Poly pipe offers superior flexibility and corrosion resistance compared to aluminum pipe, making it ideal for mainline water delivery in irrigation systems. While aluminum pipes are lightweight and easy to install, they are prone to corrosion and damage under harsh environmental conditions. Choosing poly pipe ensures durability and long-term cost efficiency in water management applications.

Table of Comparison

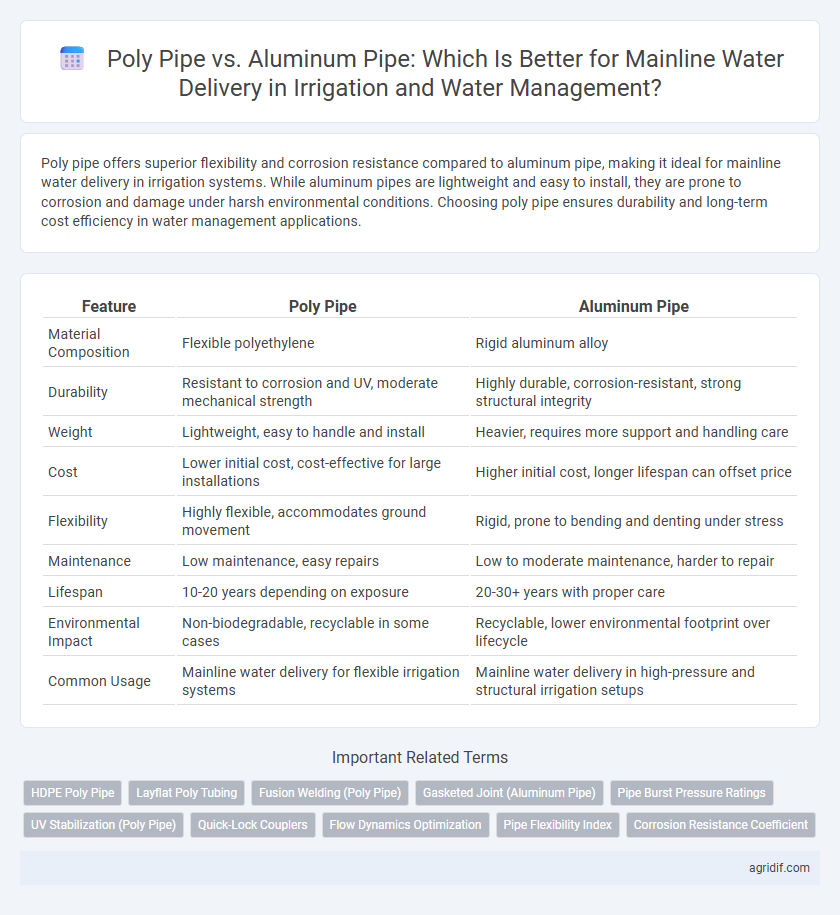

| Feature | Poly Pipe | Aluminum Pipe |

|---|---|---|

| Material Composition | Flexible polyethylene | Rigid aluminum alloy |

| Durability | Resistant to corrosion and UV, moderate mechanical strength | Highly durable, corrosion-resistant, strong structural integrity |

| Weight | Lightweight, easy to handle and install | Heavier, requires more support and handling care |

| Cost | Lower initial cost, cost-effective for large installations | Higher initial cost, longer lifespan can offset price |

| Flexibility | Highly flexible, accommodates ground movement | Rigid, prone to bending and denting under stress |

| Maintenance | Low maintenance, easy repairs | Low to moderate maintenance, harder to repair |

| Lifespan | 10-20 years depending on exposure | 20-30+ years with proper care |

| Environmental Impact | Non-biodegradable, recyclable in some cases | Recyclable, lower environmental footprint over lifecycle |

| Common Usage | Mainline water delivery for flexible irrigation systems | Mainline water delivery in high-pressure and structural irrigation setups |

Introduction: Importance of Mainline Pipe Selection in Irrigation

Selecting the appropriate mainline pipe in irrigation systems critically impacts water flow efficiency and system longevity. Poly pipes offer flexibility, corrosion resistance, and ease of installation, making them suitable for varied terrains and long-term use. In contrast, aluminum pipes provide durability and resistance to UV radiation but may incur higher costs and require more maintenance, influencing overall water management effectiveness.

Poly Pipe and Aluminum Pipe: An Overview

Poly pipe offers flexibility, durability, and resistance to corrosion, making it ideal for mainline water delivery in irrigation systems where movement and environmental exposure are factors. Aluminum pipe provides strength and lightweight characteristics but is susceptible to corrosion and denting, which can affect long-term water flow efficiency. Selecting between poly and aluminum pipes depends on site conditions, budget, and longevity requirements for effective water management.

Durability and Lifespan: Poly vs Aluminum

Poly pipes exhibit superior corrosion resistance and flexibility, making them highly durable for mainline water delivery in irrigation systems, with an average lifespan exceeding 25 years. Aluminum pipes, while lightweight and easy to install, are more prone to corrosion and physical damage, reducing their effective lifespan to approximately 10-15 years under typical irrigation conditions. Choosing poly pipes ensures longer-term reliability and lower maintenance costs in water management infrastructure.

Installation Ease and Flexibility

Poly pipes offer superior installation ease and flexibility for mainline water delivery in irrigation systems due to their lightweight nature and ability to bend around obstacles without the need for numerous fittings. Aluminum pipes, while durable and resistant to corrosion, are rigid and require precise alignment with additional connectors, increasing labor time and complexity. The adaptability of poly pipes reduces installation costs and time, making them the preferred choice for efficient water management in varied terrain.

Cost Comparison: Upfront and Maintenance

Poly pipes for mainline water delivery offer a significantly lower upfront cost compared to aluminum pipes, making them a budget-friendly choice for large-scale irrigation projects. Maintenance expenses for poly pipes remain minimal due to their resistance to corrosion and flexibility, while aluminum pipes often incur higher maintenance costs because of susceptibility to corrosion and potential damage from environmental factors. Overall, poly pipes deliver superior cost-efficiency over the entire lifecycle, especially in water management systems requiring durable and economical solutions.

Resistance to Corrosion and Weathering

Polyethylene (poly) pipes exhibit superior resistance to corrosion and weathering compared to aluminum pipes, making them ideal for mainline water delivery in irrigation systems. Unlike aluminum, which is susceptible to oxidation and can degrade when exposed to moisture and varying weather conditions, poly pipes maintain structural integrity and functionality over extended periods. This durability reduces maintenance needs and ensures consistent water flow under diverse environmental stresses.

Water Flow Efficiency and Pressure Ratings

Poly pipes offer superior water flow efficiency due to their smooth interior surface, reducing friction loss and maintaining consistent pressure over long distances. Aluminum pipes, while durable and corrosion-resistant, often have rougher interiors that increase turbulence and decrease flow efficiency in mainline water delivery. Pressure ratings for poly pipes typically range from 100 to 315 psi, accommodating various irrigation system needs more flexibly compared to aluminum pipes, which have higher pressure thresholds but less adaptability to field conditions.

Environmental Impact and Recyclability

Poly pipe used for mainline water delivery in irrigation offers high durability and flexibility with low environmental impact due to its resistance to corrosion and reduced water loss. Aluminum pipes, while lightweight and sturdy, present a higher environmental footprint from mining and processing but are highly recyclable, contributing to sustainable metal reuse. The choice between poly and aluminum pipes hinges on balancing the environmental cost of production against recyclability and long-term performance in water management systems.

Suitability for Various Crops and Soil Types

Poly pipes offer superior flexibility and corrosion resistance, making them ideal for diverse crop types and varying soil conditions, including acidic and sandy soils. Aluminum pipes are more rigid and prone to corrosion in certain soil types, which limits their suitability mainly to stable, less corrosive environments. For crops sensitive to water quality variability, poly pipes provide a more consistent delivery, enhancing overall irrigation efficiency.

Choosing the Right Pipe for Your Irrigation Needs

Poly pipe offers flexibility, corrosion resistance, and cost-effectiveness, making it ideal for low to medium pressure irrigation systems. Aluminum pipe provides superior durability and strength for high-pressure mainline water delivery but is prone to corrosion in acidic soils and requires grounding to prevent electrical issues. Selecting the right pipe depends on factors like water pressure, soil conditions, longevity requirements, and budget constraints to ensure efficient and reliable irrigation system performance.

Related Important Terms

HDPE Poly Pipe

HDPE Poly pipe is highly preferred over aluminum pipe for mainline water delivery in irrigation due to its superior flexibility, corrosion resistance, and durability under varying soil conditions. Its lightweight structure and seamless joints minimize leakage risks and enhance hydraulic efficiency, optimizing water management systems.

Layflat Poly Tubing

Layflat Poly Tubing offers superior flexibility and corrosion resistance compared to rigid aluminum pipes, making it ideal for efficient mainline water delivery in irrigation systems. Its lightweight design facilitates easier installation and maintenance while minimizing water loss through leaks, enhancing overall irrigation performance.

Fusion Welding (Poly Pipe)

Poly pipe mainline water delivery systems utilize fusion welding techniques to create seamless, leak-proof joints that ensure high durability and corrosion resistance compared to aluminum pipes. Fusion welding of poly pipes improves system integrity and reduces maintenance costs, making them ideal for efficient irrigation and water management applications.

Gasketed Joint (Aluminum Pipe)

Gasketed joints in aluminum pipes provide superior leak prevention and ease of installation compared to traditional poly pipe connections, ensuring efficient mainline water delivery in irrigation systems. Their durable rubber gaskets create a watertight seal that reduces maintenance frequency and enhances long-term system reliability under varying pressure conditions.

Pipe Burst Pressure Ratings

Poly pipes typically offer burst pressure ratings ranging from 150 to 350 psi, making them suitable for most irrigation mainline water delivery systems, whereas aluminum pipes have higher burst pressures, often exceeding 600 psi, providing superior resistance to high-pressure conditions. The choice between poly and aluminum pipes should consider the maximum operating pressure of the irrigation system and environmental factors affecting durability and flexibility.

UV Stabilization (Poly Pipe)

Poly pipes used in mainline water delivery boast superior UV stabilization, incorporating additives that prevent degradation and extend service life under prolonged sun exposure. Aluminum pipes lack intrinsic UV resistance, making poly pipes a more durable and cost-effective choice for irrigation systems exposed to harsh environmental conditions.

Quick-Lock Couplers

Poly pipes offer superior flexibility and corrosion resistance compared to aluminum pipes in mainline water delivery systems, enhancing durability under variable environmental conditions. Quick-lock couplers in poly pipe systems provide faster, tool-free connections that reduce installation time and minimize leaks, making them ideal for efficient irrigation and water management.

Flow Dynamics Optimization

Poly pipe offers superior flow dynamics optimization compared to aluminum pipe in mainline water delivery due to its smooth inner surface, which reduces friction loss and maintains consistent pressure over long distances. Aluminum pipes, while durable, have a rougher interior that increases turbulence and flow resistance, leading to reduced hydraulic efficiency in irrigation systems.

Pipe Flexibility Index

Poly pipes exhibit a high Pipe Flexibility Index, allowing easier installation around bends and uneven terrains without the need for extensive fittings, which reduces labor costs and potential leak points. In contrast, aluminum pipes possess a low flexibility index, making them rigid, less adaptable to varied landscapes, and more prone to damage under stress during mainline water delivery in irrigation systems.

Corrosion Resistance Coefficient

Poly pipe demonstrates a significantly higher Corrosion Resistance Coefficient compared to aluminum pipes, ensuring longer service life and reduced maintenance costs in mainline water delivery systems. Aluminum pipes are prone to oxidation and galvanic corrosion, especially in acidic or saline environments, resulting in lower corrosion resistance and potential water contamination.

Poly pipe vs Aluminum pipe for mainline water delivery Infographic

agridif.com

agridif.com