Mechanical weeders provide precise soil disturbance that effectively uproots weeds in row crops without chemical use, promoting healthier plant growth and soil structure. Flame weeding offers a non-chemical alternative by applying targeted heat to destroy weed seedlings, reducing herbicide reliance but requiring careful timing to avoid crop damage. Both methods support sustainable organic farming practices by minimizing environmental impact while maintaining weed control efficiency.

Table of Comparison

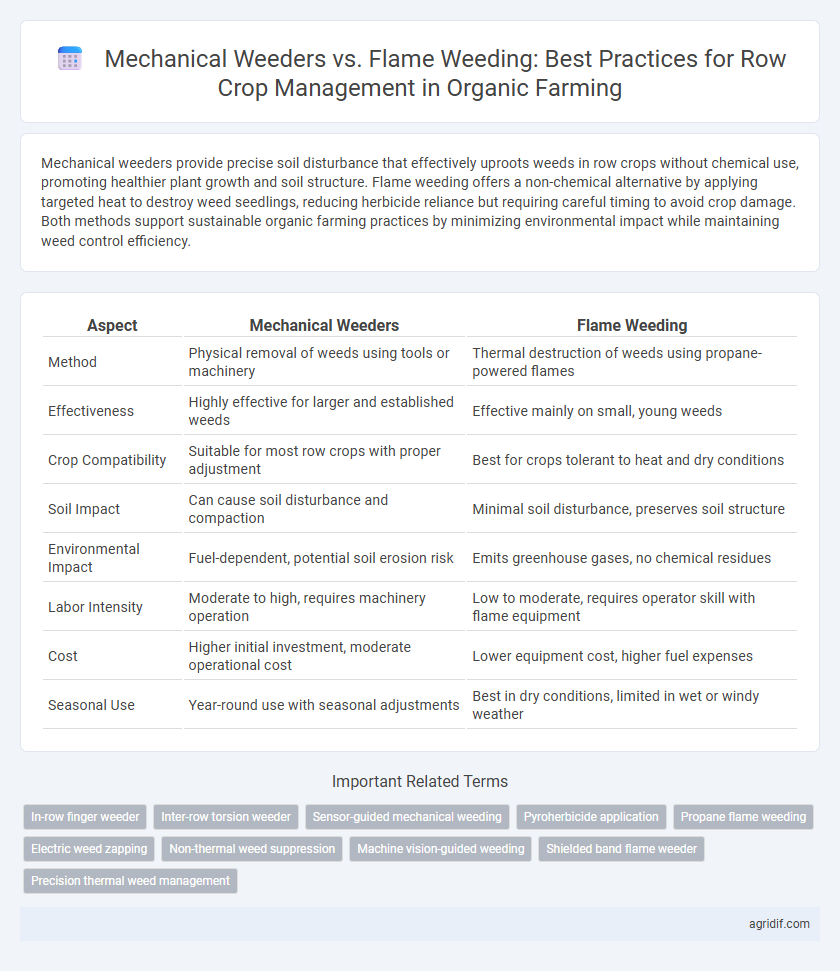

| Aspect | Mechanical Weeders | Flame Weeding |

|---|---|---|

| Method | Physical removal of weeds using tools or machinery | Thermal destruction of weeds using propane-powered flames |

| Effectiveness | Highly effective for larger and established weeds | Effective mainly on small, young weeds |

| Crop Compatibility | Suitable for most row crops with proper adjustment | Best for crops tolerant to heat and dry conditions |

| Soil Impact | Can cause soil disturbance and compaction | Minimal soil disturbance, preserves soil structure |

| Environmental Impact | Fuel-dependent, potential soil erosion risk | Emits greenhouse gases, no chemical residues |

| Labor Intensity | Moderate to high, requires machinery operation | Low to moderate, requires operator skill with flame equipment |

| Cost | Higher initial investment, moderate operational cost | Lower equipment cost, higher fuel expenses |

| Seasonal Use | Year-round use with seasonal adjustments | Best in dry conditions, limited in wet or windy weather |

Introduction to Weed Control in Organic Row Crops

Mechanical weeders in organic row crop management offer precise soil disturbance that disrupts weed growth while preserving crop roots, making them highly effective for early-stage weed control. Flame weeding applies targeted heat to weed seedlings, causing cell damage and suppressing weed emergence without chemical residues, ideal for use in organic systems. Combining both methods enhances weed management by reducing weed seed banks and promoting healthier crop development in organic farming practices.

What Are Mechanical Weeders?

Mechanical weeders are specialized agricultural tools designed to uproot or dislodge weeds from the soil without harming row crops, using methods such as hoeing, cultivating, or rotary tilling. These machines enhance soil aeration and reduce weed competition by physically disturbing weed roots, promoting healthier crop growth in organic farming systems. Compared to flame weeding, mechanical weeders offer precise targeting of weeds, minimizing the risk of crop damage from heat exposure and providing a sustainable alternative for integrated weed management.

Understanding Flame Weeding Techniques

Flame weeding uses directed heat to disrupt weed cell structure, effectively controlling early-stage weed growth in row crops without disturbing soil integrity. This technique reduces reliance on mechanical weeders by targeting weed seedlings with precise thermal radiation, minimizing crop damage and promoting soil microbiome health. Understanding optimal flame intensity, exposure time, and environmental conditions is crucial for maximizing herbicidal efficiency while maintaining sustainable organic farming practices.

Comparative Effectiveness: Mechanical vs Flame Weed Control

Mechanical weeders provide targeted soil disturbance, effectively uprooting weeds within row crops while minimizing crop damage through precise adjustment. Flame weeding uses heat to desiccate weed tissues, delivering rapid control but often requiring careful timing to avoid crop injury and repeated applications for persistent weeds. Studies indicate mechanical weeders excel in consistent long-term control and soil aeration benefits, whereas flame weeding proves efficient for quick suppression of small annual weeds in organic row crop systems.

Soil Health Impacts of Mechanical and Flame Weeding

Mechanical weeders promote soil aeration and structure by disturbing the topsoil, enhancing microbial activity and nutrient cycling in organic row crop systems. Flame weeding, while effective in controlling weeds without soil disruption, may reduce soil microbial biomass and organic matter over time due to heat exposure. Balancing mechanical and flame weeding techniques optimizes weed control while maintaining long-term soil health and fertility.

Environmental Considerations: Emissions and Residues

Mechanical weeders produce minimal emissions and leave no chemical residues, making them environmentally preferable for row crop management. Flame weeding generates greenhouse gases and poses risks of residual combustion by-products that can affect soil health. Choosing mechanical weeders supports sustainable farming by reducing pollution and preserving soil ecosystems.

Cost Analysis: Equipment, Fuel, and Labor

Mechanical weeders for row crop management require significant upfront investment in specialized equipment but offer lower ongoing fuel costs compared to flame weeding, which demands continuous propane consumption. Labor costs for mechanical weeding are generally higher due to slower operation speeds and frequent adjustments, whereas flame weeding can reduce manual labor time but increases fuel expenses. Overall, mechanical weeders may provide cost advantages in large-scale operations with available labor, while flame weeding suits smaller farms prioritizing reduced labor despite higher fuel costs.

Crop Safety and Selectivity in Weed Management

Mechanical weeders offer precise soil disturbance mainly around crop rows, minimizing crop damage while effectively uprooting weeds. Flame weeding uses controlled heat to desiccate weed seedlings without soil disruption, but careful application is critical to prevent crop injury, especially in sensitive row crops. Selecting between these methods depends on crop tolerance, growth stage, and weed species, with mechanical weeders often preferred for greater selectivity and crop safety in organic row crop management.

Farmer Experiences and Practical Challenges

Farmers report mechanical weeders provide precise soil cultivation and effective weed control in row crops, but often require multiple passes and can be labor-intensive. Flame weeding offers rapid weed suppression with minimal soil disturbance, yet challenges include fuel costs, safety concerns, and limited efficacy against deep-rooted weeds. Practical experiences highlight the necessity to balance operational costs, environmental impact, and crop sensitivity when selecting between these two organic weed management methods.

Conclusion: Best Practices for Organic Weed Control

Mechanical weeders provide precise weed removal in row crop management, minimizing soil disruption and preserving crop health. Flame weeding offers rapid, chemical-free destruction of young weed seedlings but may risk crop injury if misapplied. The best practice for organic weed control combines mechanical weeding for targeted removal with flame weeding for early-stage weed suppression, optimizing crop yield and soil integrity.

Related Important Terms

In-row finger weeder

The in-row finger weeder offers precise mechanical weed control in organic row crop management by disturbing soil around crops without harming them, enhancing soil aeration and promoting healthy root development. Unlike flame weeding, which uses thermal energy to eliminate weeds, finger weeders minimize crop damage and reduce energy use, making them a sustainable choice for organic farmers seeking efficient, chemical-free weed management.

Inter-row torsion weeder

Inter-row torsion weeders offer precise mechanical weed control for row crops, effectively disrupting weed growth without damaging the crop plants or soil structure. Flame weeding, while efficient for surface weed suppression, risks crop injury and soil microorganism disruption, making torsion weeders a preferred choice for sustainable organic farming practices.

Sensor-guided mechanical weeding

Sensor-guided mechanical weeders leverage advanced imaging and AI technology to precisely target weeds in row crops, reducing crop damage and improving weed control efficiency compared to traditional flame weeding, which uses heat to destroy weeds but may risk crop injury and soil microbiome disruption. This technology enhances organic farming practices by minimizing chemical use, promoting soil health, and optimizing labor input through automated, site-specific interventions.

Pyroherbicide application

Mechanical weeders provide precise physical disturbance to control weeds in row crops, promoting soil aeration and reducing compaction; pyroherbicide application through flame weeding offers effective thermal weed control by causing cellular damage without chemical residues. Pyroherbicide technology enhances organic farming sustainability by minimizing herbicide reliance, improving weed management efficiency in crops like corn and soybeans.

Propane flame weeding

Propane flame weeding offers precise control of weeds in row crop management by targeting weed seedlings with intense heat, effectively disrupting cellular structures without soil disturbance. This method reduces soil erosion and preserves beneficial microorganisms compared to mechanical weeders, which rely on physical disruption and may damage crop roots or compact the soil.

Electric weed zapping

Electric weed zapping in organic farming offers precise, energy-efficient mechanical weed control by targeting weed stems with electric currents, reducing crop damage compared to traditional flame weeding. This method minimizes soil disturbance and eliminates the fire risk associated with flame weeding, making it a safer and more sustainable option for row crop management.

Non-thermal weed suppression

Mechanical weeders provide effective non-thermal weed suppression by physically uprooting weeds in row crop management, maintaining soil structure and minimizing chemical use. Flame weeding, while commonly recognized for thermal weed control, can also support non-thermal weed suppression by selectively damaging weed seedlings' tissues without extensive soil disturbance.

Machine vision-guided weeding

Machine vision-guided mechanical weeders utilize advanced sensors and AI algorithms to precisely identify and remove weeds in row crops, significantly reducing crop damage and enhancing weed control efficiency compared to traditional flame weeding. This technology enables targeted, eco-friendly weed management by minimizing soil disturbance and eliminating the use of heat, promoting sustainable organic farming practices.

Shielded band flame weeder

Shielded band flame weeders offer precise heat application for row crop management, effectively targeting weeds without damaging adjacent crops, making them ideal for organic farming. These mechanical weeders reduce reliance on manual labor and chemical herbicides, enhancing weed control efficiency and promoting sustainable crop yields.

Precision thermal weed management

Mechanical weeders offer targeted soil disturbance to remove weeds in row crops, enhancing soil aeration and minimizing crop damage, while flame weeding utilizes precise thermal energy to disrupt weed cell structure, effectively controlling weeds without soil disruption. Precision thermal weed management with flame weeding reduces herbicide reliance, lowers carbon footprint, and improves crop health by selectively targeting weed seedlings in early growth stages.

Mechanical weeders vs flame weeding for row crop management Infographic

agridif.com

agridif.com