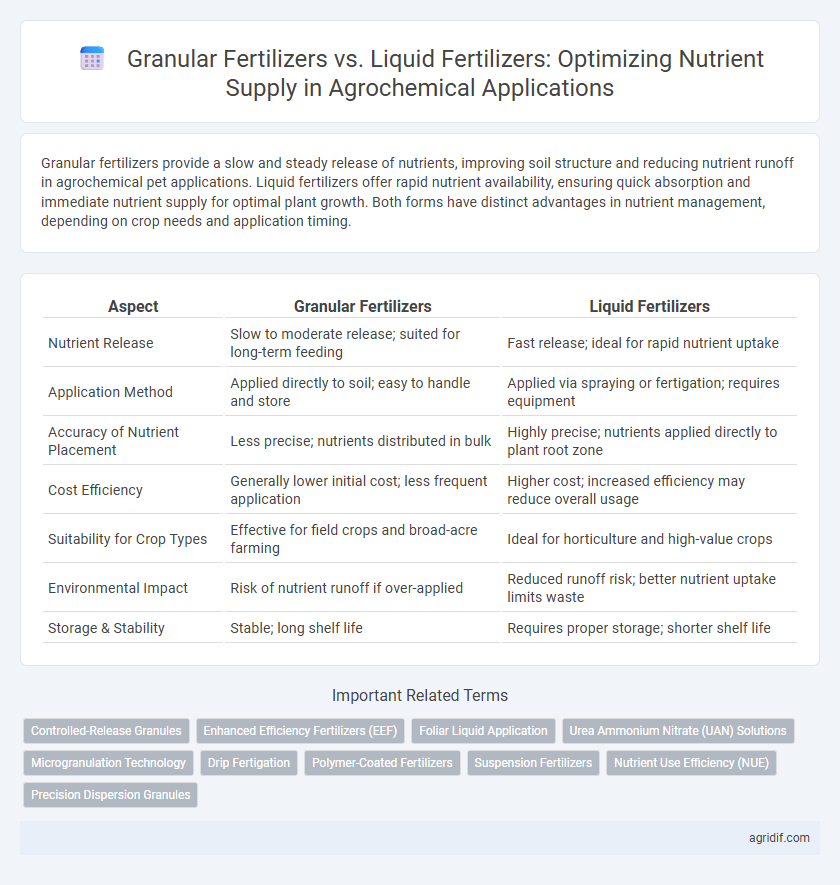

Granular fertilizers provide a slow and steady release of nutrients, improving soil structure and reducing nutrient runoff in agrochemical pet applications. Liquid fertilizers offer rapid nutrient availability, ensuring quick absorption and immediate nutrient supply for optimal plant growth. Both forms have distinct advantages in nutrient management, depending on crop needs and application timing.

Table of Comparison

| Aspect | Granular Fertilizers | Liquid Fertilizers |

|---|---|---|

| Nutrient Release | Slow to moderate release; suited for long-term feeding | Fast release; ideal for rapid nutrient uptake |

| Application Method | Applied directly to soil; easy to handle and store | Applied via spraying or fertigation; requires equipment |

| Accuracy of Nutrient Placement | Less precise; nutrients distributed in bulk | Highly precise; nutrients applied directly to plant root zone |

| Cost Efficiency | Generally lower initial cost; less frequent application | Higher cost; increased efficiency may reduce overall usage |

| Suitability for Crop Types | Effective for field crops and broad-acre farming | Ideal for horticulture and high-value crops |

| Environmental Impact | Risk of nutrient runoff if over-applied | Reduced runoff risk; better nutrient uptake limits waste |

| Storage & Stability | Stable; long shelf life | Requires proper storage; shorter shelf life |

Introduction to Granular and Liquid Fertilizers

Granular fertilizers consist of solid, dry particles that release nutrients slowly, offering precise nutrient management and longer-lasting soil enrichment. Liquid fertilizers provide nutrients in a soluble form, allowing for rapid absorption and immediate availability to plants, which is ideal for correcting nutrient deficiencies quickly. Both types play critical roles in modern agrochemical practices by addressing specific crop needs based on soil conditions and growth stages.

Composition and Forms of Granular vs Liquid Fertilizers

Granular fertilizers consist of solid particles that release nutrients gradually, often containing nitrogen, phosphorus, potassium, and micronutrients in a balanced form ideal for long-term nutrient supply. Liquid fertilizers are primarily aqueous solutions or suspensions containing readily available nutrients like nitrogen and micronutrients, allowing for rapid absorption through foliar feeding or soil application. The physical state of granular fertilizers enables slow nutrient release and soil conditioning, while liquid fertilizers provide precise nutrient management and immediate plant uptake.

Nutrient Release Profiles: Granular vs Liquid

Granular fertilizers provide a slow and controlled nutrient release, improving nutrient uptake efficiency over time by plants, which suits long-term crop nutrition strategies. Liquid fertilizers deliver nutrients rapidly, allowing for immediate availability and targeted application during critical growth stages, enhancing precision in nutrient management. Choosing between granular and liquid forms depends on crop needs, soil conditions, and timing of nutrient supply to optimize agricultural productivity.

Application Methods for Both Fertilizer Types

Granular fertilizers are typically applied through broadcasting, banding, or side-dressing, allowing for targeted nutrient placement near the root zone, which enhances nutrient uptake efficiency. Liquid fertilizers are often delivered via foliar sprays, fertigation systems, or injection into irrigation water, enabling rapid nutrient absorption and uniform distribution across crops. Each application method affects the nutrient availability and environmental impact, making choice dependent on crop type, soil conditions, and irrigation practices.

Efficiency of Nutrient Uptake

Granular fertilizers release nutrients gradually, enhancing root absorption over time and improving long-term nutrient retention in soil. Liquid fertilizers provide immediate nutrient availability, promoting rapid uptake by plants and quick correction of deficiencies. Efficiency of nutrient uptake depends on crop type, soil conditions, and timing of application, with liquid fertilizers offering precision and quick response while granular types support sustained nutrition.

Suitability for Different Crops and Soils

Granular fertilizers offer precise nutrient release beneficial for crops requiring steady nutrient supply, thriving in well-drained or sandy soils, while liquid fertilizers provide rapid nutrient availability ideal for high-demand crops and soils needing immediate correction. Crops like cereals and root vegetables benefit from granular forms due to controlled nutrient release, whereas vegetables and fruit crops respond better to liquid fertilizers for quick uptake. Soil texture and moisture conditions largely influence the effectiveness, with granular fertilizers suited to less frequent applications in coarse soils and liquid formulations favored in fine or compacted soils requiring uniform nutrient distribution.

Cost Considerations and Economic Impact

Granular fertilizers typically offer lower upfront costs and longer shelf life, making them economically attractive for bulk nutrient supply in large-scale farming. Liquid fertilizers, while generally more expensive per unit, allow precise application and faster nutrient uptake, potentially increasing crop yield efficiency and reducing overall input costs. Cost considerations must balance initial investment with long-term economic impact based on crop type, soil condition, and application technology.

Environmental Implications and Runoff Risks

Granular fertilizers tend to release nutrients slowly, reducing immediate runoff risks but increasing the potential for nutrient accumulation in soil and groundwater contamination over time. Liquid fertilizers offer rapid nutrient availability but pose higher risks of leaching and surface runoff, especially during heavy rainfall, leading to eutrophication in nearby water bodies. Environmental implications highlight the trade-off between nutrient efficiency and potential water pollution, emphasizing the need for precision application based on soil type and climate conditions.

Storage, Handling, and Safety Aspects

Granular fertilizers offer superior storage stability with lower risk of spillage and easier handling due to their solid form, reducing safety hazards related to chemical exposure. Liquid fertilizers require specialized containers and storage conditions to prevent leakage, corrosion, and contamination, increasing handling complexity and potential health risks. Proper training and equipment are essential for safe application of both forms, but granular fertilizers generally present fewer safety concerns during transport and storage.

Choosing the Right Fertilizer for Optimal Yield

Granular fertilizers provide slow-release nutrients that enhance soil structure and support long-term crop growth, making them ideal for steady nutrient supply. Liquid fertilizers offer rapid nutrient uptake and precise application, allowing for timely correction of nutrient deficiencies during critical growth stages. Selecting the right fertilizer depends on crop type, soil conditions, and nutrient management goals to maximize yield and improve plant health.

Related Important Terms

Controlled-Release Granules

Controlled-release granules in agrochemicals provide a precise nutrient supply by slowly releasing essential elements, minimizing nutrient loss and enhancing plant uptake efficiency compared to liquid fertilizers. These granules optimize soil nutrient availability over time, reducing leaching and promoting sustainable crop growth with improved yield consistency.

Enhanced Efficiency Fertilizers (EEF)

Granular fertilizers, particularly Enhanced Efficiency Fertilizers (EEFs), provide controlled nutrient release, improving uptake efficiency and reducing environmental losses compared to traditional liquid fertilizers. Liquid fertilizers offer rapid nutrient availability but often require frequent applications, whereas EEFs optimize nutrient use by incorporating inhibitors and slow-release technologies that enhance crop yield and sustainability in agrochemical nutrient management.

Foliar Liquid Application

Foliar liquid fertilizers enhance nutrient uptake efficiency by delivering essential micronutrients directly to plant leaves, promoting rapid absorption and targeted nutrient supply compared to slower-release granular fertilizers. This method minimizes nutrient losses through leaching and volatilization, optimizing plant growth and improving crop yields in precision agrochemical applications.

Urea Ammonium Nitrate (UAN) Solutions

Granular fertilizers provide a slow and controlled nutrient release ideal for steady crop growth, while Urea Ammonium Nitrate (UAN) solutions deliver nitrogen in a readily available liquid form, enhancing rapid absorption and uniform application. UAN solutions combine urea and ammonium nitrate, offering flexibility in fertigation and foliar feeding, which improves nitrogen use efficiency compared to traditional granular forms.

Microgranulation Technology

Microgranulation technology enhances granular fertilizers by producing uniform, fine particles that improve nutrient release control and soil adherence compared to conventional liquid fertilizers, which offer rapid nutrient availability but may suffer from leaching. This technology optimizes nutrient use efficiency, particularly for micronutrients, ensuring precise delivery and sustained supply in various soil conditions.

Drip Fertigation

Granular fertilizers provide a controlled release of nutrients, ideal for sustained feeding in drip fertigation systems, while liquid fertilizers offer rapid nutrient availability and precise application through drip lines. Optimizing fertilizer type in drip fertigation enhances nutrient use efficiency, crop yield, and minimizes environmental impact.

Polymer-Coated Fertilizers

Polymer-coated granular fertilizers offer controlled nutrient release, reducing leaching and enhancing efficiency compared to liquid fertilizers, which provide immediate but often short-lived nutrient availability. This gradual release mechanism improves crop uptake and minimizes environmental impact, making polymer-coated granules a sustainable choice for precise nutrient management in agrochemical applications.

Suspension Fertilizers

Suspension fertilizers, a type of liquid fertilizer, provide uniform nutrient distribution and improved nutrient availability compared to granular fertilizers, enhancing crop uptake efficiency. These formulations maintain stable nutrient suspensions, ensuring consistent application rates and minimizing nutrient losses in the soil.

Nutrient Use Efficiency (NUE)

Granular fertilizers demonstrate higher Nutrient Use Efficiency (NUE) by releasing nutrients slowly and reducing leaching, which enhances root uptake and minimizes environmental losses. Liquid fertilizers offer rapid nutrient availability but often exhibit lower NUE due to potential runoff and volatilization, limiting sustained nutrient supply to crops.

Precision Dispersion Granules

Granular fertilizers provide precise nutrient supply through controlled release and targeted application, minimizing nutrient loss and enhancing soil absorption efficiency. Precision Dispersion Granules optimize nutrient delivery by ensuring uniform distribution and reducing environmental impact compared to liquid fertilizers, which may suffer from runoff and uneven application.

Granular fertilizers vs liquid fertilizers for nutrient supply Infographic

agridif.com

agridif.com