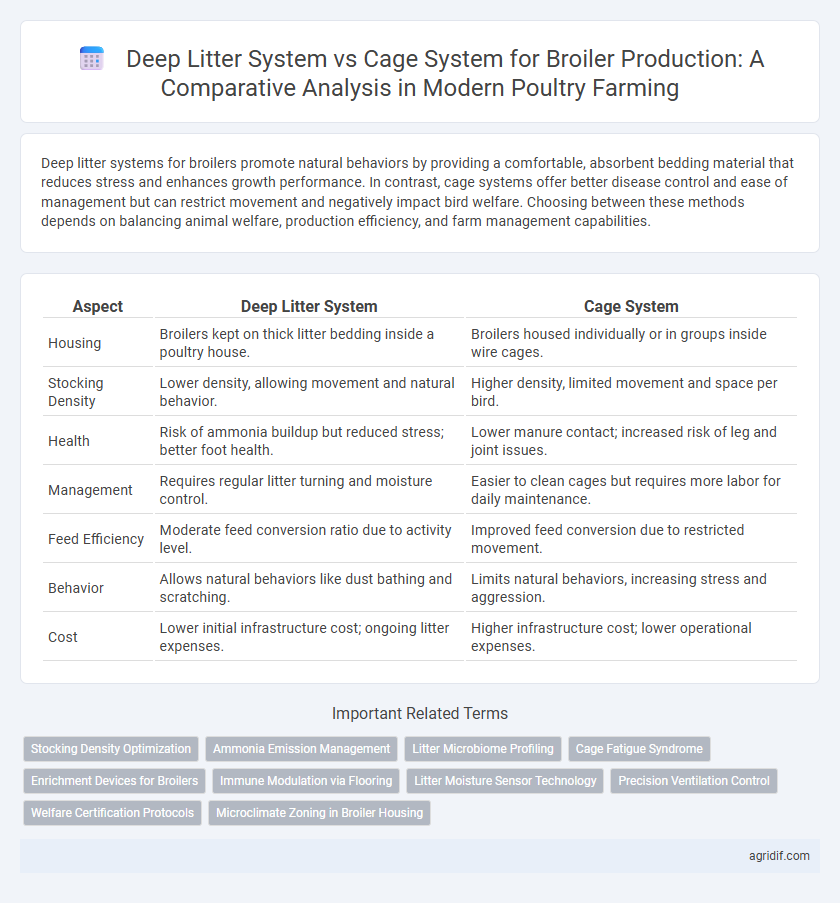

Deep litter systems for broilers promote natural behaviors by providing a comfortable, absorbent bedding material that reduces stress and enhances growth performance. In contrast, cage systems offer better disease control and ease of management but can restrict movement and negatively impact bird welfare. Choosing between these methods depends on balancing animal welfare, production efficiency, and farm management capabilities.

Table of Comparison

| Aspect | Deep Litter System | Cage System |

|---|---|---|

| Housing | Broilers kept on thick litter bedding inside a poultry house. | Broilers housed individually or in groups inside wire cages. |

| Stocking Density | Lower density, allowing movement and natural behavior. | Higher density, limited movement and space per bird. |

| Health | Risk of ammonia buildup but reduced stress; better foot health. | Lower manure contact; increased risk of leg and joint issues. |

| Management | Requires regular litter turning and moisture control. | Easier to clean cages but requires more labor for daily maintenance. |

| Feed Efficiency | Moderate feed conversion ratio due to activity level. | Improved feed conversion due to restricted movement. |

| Behavior | Allows natural behaviors like dust bathing and scratching. | Limits natural behaviors, increasing stress and aggression. |

| Cost | Lower initial infrastructure cost; ongoing litter expenses. | Higher infrastructure cost; lower operational expenses. |

Introduction to Broiler Housing Systems

Broiler housing systems primarily include the deep litter and cage systems, each designed to optimize poultry production efficiency and animal welfare. The deep litter system involves birds reared on bedding material that absorbs moisture and waste, promoting natural behaviors and environmental enrichment. In contrast, the cage system confines broilers in individual or group cages, maximizing space utilization and facilitating management but potentially limiting movement and behavioral expression.

Overview of Deep Litter System

The Deep Litter System for broilers involves raising birds on a thick layer of bedding material such as wood shavings, rice hulls, or straw, which absorbs moisture and manure, promoting microbial activity that breaks down waste. This system enhances bird welfare by allowing natural behaviors like scratching and dust bathing, reduces stress compared to cage systems, and improves air quality through litter management. Deep litter systems support sustainable waste management and reduce labor costs by minimizing the frequency of cleaning compared to conventional cage-based broiler production.

Overview of Cage System

The cage system for broilers involves housing birds in wire or metal cages that allow easy waste removal and better disease control compared to deep litter systems. This method optimizes space utilization and promotes uniform growth by limiting movement, which can reduce feed conversion ratios. However, cage systems may affect bird welfare due to restricted mobility and natural behaviors.

Performance and Growth Rates

Deep litter systems for broilers often promote better growth rates and overall performance due to improved natural behaviors and comfort, resulting in lower stress and enhanced feed conversion ratios. Cage systems, while offering controlled environments and ease of management, may restrict movement, potentially leading to slower growth rates and higher incidence of leg disorders. Studies indicate that broilers in deep litter setups can achieve weight gains up to 10-15% higher compared to those raised in conventional cages.

Health and Welfare Considerations

Deep litter systems for broilers promote natural behaviors such as dust bathing and scratching, leading to improved leg health and reduced stress levels compared to cage systems. Cage systems often restrict movement, increasing the risk of skeletal problems and negatively impacting overall welfare. Proper management of deep litter with regular cleaning and ventilation is essential to minimize disease risks and maintain optimal bird health.

Feed and Resource Management

Deep litter systems for broilers enhance feed efficiency by allowing natural behaviors such as foraging, reducing feed wastage compared to cage systems where feed spillage is common. Resource management in deep litter setups benefits from the recycling of bedding materials that absorb moisture and manure, minimizing the need for frequent cleaning and lowering water consumption. In contrast, cage systems demand more intensive resource inputs for waste removal and ventilation, increasing operational costs associated with feed and environmental control.

Labor and Operational Costs

The deep litter system for broilers generally reduces labor costs by minimizing daily cleaning and maintenance compared to the cage system, which requires frequent cage cleaning and waste management. Operational expenses in the deep litter method tend to be lower due to less water usage and reduced equipment needs, while the cage system incurs higher costs from regular disinfecting and ventilation requirements. Overall, deep litter systems offer more economical labor and operational efficiencies, particularly in large-scale broiler production.

Environmental Impact and Waste Management

Deep litter systems for broilers generate less concentrated waste compared to cage systems, facilitating natural decomposition and reducing the need for extensive manure handling. Cage systems produce high volumes of concentrated excreta, leading to increased ammonia emissions and potential soil and water contamination if not properly managed. Proper waste management techniques in deep litter systems support nutrient recycling and lower environmental pollution, making them more sustainable in the context of animal husbandry.

Productivity and Profitability Comparison

The deep litter system for broilers enhances productivity by promoting natural behaviors and improving bird welfare, leading to better feed conversion ratios and weight gain compared to the cage system. Profitability in the deep litter approach benefits from lower infrastructure costs and reduced labor in cleaning, while cage systems require higher initial investments and maintenance expenses. Studies indicate that deep litter setups yield higher net returns per bird due to combined improvements in growth performance and cost efficiency.

Conclusion: Choosing the Optimal System

Selecting the optimal system for broiler production hinges on balancing animal welfare, production efficiency, and cost-effectiveness. Deep litter systems promote natural behaviors and better foot health, leading to improved overall welfare, while cage systems offer higher stock density and easier disease control. Producers must evaluate their specific operational goals and environmental constraints to make an informed decision.

Related Important Terms

Stocking Density Optimization

Deep litter systems for broilers enable higher stocking density optimization by providing a natural environment that enhances bird welfare and reduces stress-related behaviors compared to cage systems. Cage systems often restrict movement, limiting stocking density to prevent health issues, whereas deep litter allows better distribution of birds, optimizing space utilization and improving overall growth performance.

Ammonia Emission Management

Deep litter systems for broilers significantly reduce ammonia emissions compared to cage systems by promoting microbial degradation of nitrogenous waste within the bedding material. Efficient ventilation combined with regular litter management in deep litter systems minimizes ammonia volatilization, enhancing air quality and bird welfare.

Litter Microbiome Profiling

Litter microbiome profiling reveals that deep litter systems promote a diverse microbial community beneficial for broiler gut health and pathogen suppression, whereas cage systems exhibit limited microbial diversity with higher risks of pathogenic outbreaks. Optimizing litter management based on microbiome data enhances broiler performance and reduces reliance on antibiotics.

Cage Fatigue Syndrome

Deep litter systems for broilers reduce the risk of Cage Fatigue Syndrome by allowing natural behaviors such as scratching and dust bathing, which improve bird welfare and reduce stress-related disorders. In contrast, cage systems often restrict movement, leading to muscle weakness, skeletal problems, and increased incidence of Cage Fatigue Syndrome.

Enrichment Devices for Broilers

Enrichment devices in deep litter systems for broilers, such as perches, pecking objects, and dust baths, promote natural behaviors and improve welfare by reducing stress and aggression compared to cage systems. Cage systems often limit the use of enrichment tools due to space constraints, resulting in restricted movement and diminished behavioral expression in broilers.

Immune Modulation via Flooring

Deep litter flooring in broiler production enhances immune modulation by promoting beneficial microbial interactions and reducing stress through natural behaviors, which supports stronger immune responses. In contrast, cage systems limit movement and microbial exposure, often leading to compromised immunity and increased susceptibility to pathogens.

Litter Moisture Sensor Technology

Litter moisture sensor technology in deep litter systems for broilers allows real-time monitoring and control of moisture levels, reducing ammonia emissions and improving bird welfare compared to traditional cage systems. Accurate moisture detection enhances litter quality, minimizes footpad dermatitis incidents, and supports sustainable animal husbandry practices by optimizing environmental conditions.

Precision Ventilation Control

Precision ventilation control in deep litter systems enhances broiler health by maintaining optimal air quality and humidity levels, reducing ammonia concentration and respiratory issues. In contrast, cage systems often require more complex mechanical ventilation setups to ensure consistent airflow, which can increase operational costs and energy consumption.

Welfare Certification Protocols

Deep litter systems promote natural behaviors and improved welfare outcomes for broilers by providing bedding that minimizes stress and encourages movement, aligning with welfare certification protocols such as those from RSPCA and Global Animal Partnership. Cage systems often restrict mobility and natural behaviors, posing challenges for meeting high welfare certification standards that emphasize environmental enrichment and animal well-being.

Microclimate Zoning in Broiler Housing

Deep litter systems in broiler housing enhance microclimate zoning by providing layered bedding that absorbs moisture and facilitates natural temperature gradients, improving bird comfort and health. Cage systems limit microclimate variation, potentially increasing heat stress and ammonia concentration due to restricted airflow and concentrated waste areas.

Deep Litter vs Cage System for Broilers Infographic

agridif.com

agridif.com