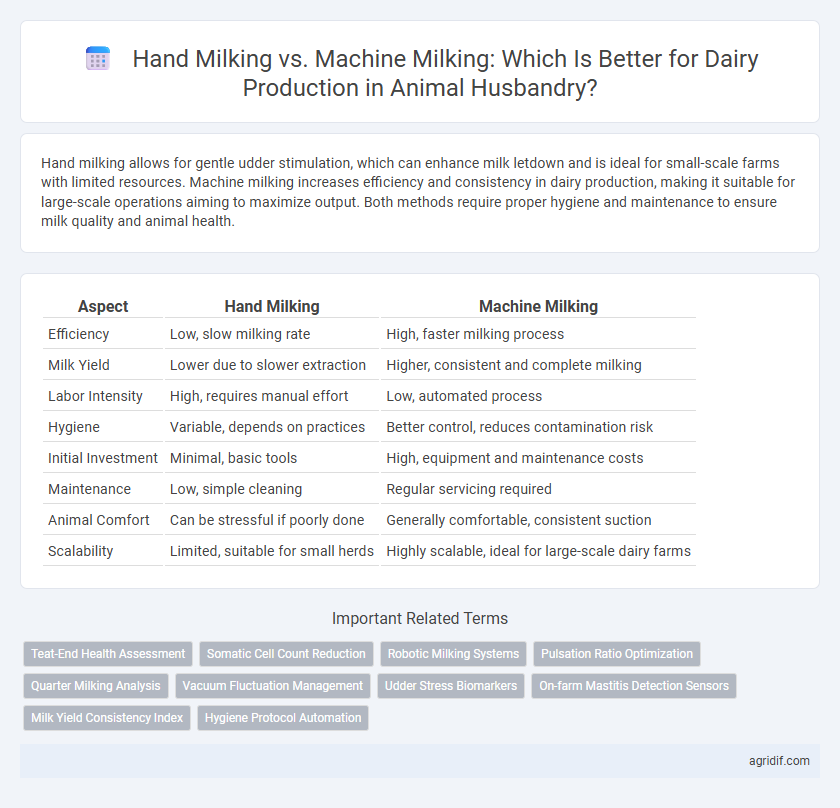

Hand milking allows for gentle udder stimulation, which can enhance milk letdown and is ideal for small-scale farms with limited resources. Machine milking increases efficiency and consistency in dairy production, making it suitable for large-scale operations aiming to maximize output. Both methods require proper hygiene and maintenance to ensure milk quality and animal health.

Table of Comparison

| Aspect | Hand Milking | Machine Milking |

|---|---|---|

| Efficiency | Low, slow milking rate | High, faster milking process |

| Milk Yield | Lower due to slower extraction | Higher, consistent and complete milking |

| Labor Intensity | High, requires manual effort | Low, automated process |

| Hygiene | Variable, depends on practices | Better control, reduces contamination risk |

| Initial Investment | Minimal, basic tools | High, equipment and maintenance costs |

| Maintenance | Low, simple cleaning | Regular servicing required |

| Animal Comfort | Can be stressful if poorly done | Generally comfortable, consistent suction |

| Scalability | Limited, suitable for small herds | Highly scalable, ideal for large-scale dairy farms |

Introduction to Milking Methods in Dairy Farming

Hand milking involves manually extracting milk from dairy animals using traditional techniques, favored in small-scale or organic farms for its low-cost setup and gentle handling. Machine milking utilizes automated milking machines, increasing efficiency, consistency, and hygiene in large-scale dairy operations, thereby enhancing productivity and reducing labor intensity. Both methods impact milk quality and animal welfare differently, influencing farm management decisions based on scale, economic factors, and output goals.

Overview of Hand Milking: Techniques and Equipment

Hand milking involves manually extracting milk from dairy animals using a coordinated thumb and forefinger grip to compress and release the teat, relying on skilled techniques to ensure efficiency and animal comfort. Essential equipment includes sanitized stainless steel milk pails, milking stools, and clean cloths for teat wiping to maintain hygiene and prevent contamination. Mastery of hand milking techniques, such as proper hand positioning and rhythm, directly influences milk yield and quality in small-scale or resource-limited dairy operations.

Machine Milking: How It Works and Required Technologies

Machine milking in dairy production relies on vacuum pumps, pulsators, and teat cups to extract milk efficiently while ensuring udder health. The vacuum creates a gentle suction that mimics a calf's natural suckling, while pulsators alternate suction and rest phases to prevent teat damage. Advanced technologies like automated cluster removers, milk flow sensors, and data integration systems optimize milking speed, hygiene, and milk quality monitoring in modern dairy farms.

Labor Efficiency: Comparing Hand Milking and Machine Milking

Machine milking significantly enhances labor efficiency in dairy production by reducing the time and physical effort required per cow compared to hand milking, enabling farmers to manage larger herds with fewer workers. Automated systems provide consistent milking speeds and routines, leading to improved overall productivity and reduced labor costs. While hand milking offers flexibility in small-scale or remote setups, machine milking remains the preferred method in commercial operations due to its scalability and labor-saving advantages.

Milk Quality and Hygiene: Manual vs Automated Approaches

Hand milking often results in higher milk quality due to the gentle extraction process that minimizes teat damage and contamination. Machine milking systems enhance hygiene by reducing human contact, utilizing automatic cleaning protocols to maintain sanitation and prevent bacterial growth. However, improper machine maintenance can lead to increased somatic cell counts and milk contamination, making consistent equipment hygiene critical for optimal dairy production.

Animal Welfare Considerations in Milking Practices

Hand milking allows for gentle handling of dairy animals, reducing stress and promoting better udder health compared to machine milking, which can sometimes cause teat damage if improperly adjusted. Machine milking offers efficiency and consistency but requires regular maintenance and monitoring to prevent discomfort and mastitis. Prioritizing animal welfare involves balancing milking technique, frequency, and equipment hygiene to ensure cattle well-being and optimal milk quality.

Cost Analysis: Investment and Operational Expenses

Hand milking requires minimal initial investment with basic tools and low operational costs primarily involving labor, making it suitable for small-scale dairy farms. Machine milking demands significant capital expenditure on milking equipment and maintenance, as well as higher energy and repair costs, though it enhances efficiency for large-scale operations. Cost analysis reveals that while hand milking minimizes upfront expenses, machine milking offers long-term savings through increased productivity and reduced labor intensity.

Suitability for Small-Scale and Large-Scale Dairy Operations

Hand milking offers greater suitability for small-scale dairy operations due to lower initial costs, ease of use, and the ability to maintain close animal contact, which benefits herd health monitoring. Machine milking significantly enhances efficiency and consistency in large-scale dairy farms by enabling faster milking times, improved hygiene, and reduced labor requirements. Small-scale farmers often rely on hand milking for flexibility and affordability, whereas commercial dairy producers invest in automated systems to support high-volume milk production and stringent quality standards.

Environmental Impact of Milking Methods

Hand milking reduces energy consumption and lowers carbon emissions compared to machine milking, making it an eco-friendly option for small-scale dairy farms. Machine milking increases water use and electricity demand due to mechanized cleaning and operation, contributing to a larger environmental footprint. Efficient maintenance and renewable energy integration in machine milking systems can mitigate some negative environmental impacts in large dairy production.

Future Trends in Dairy Milking Technologies

Emerging advancements in dairy milking technologies emphasize automation, precision monitoring, and animal welfare, driving a shift from traditional hand milking to high-efficiency machine milking systems. Innovations such as robotic milking machines integrated with IoT sensors enable real-time data collection on milk yield, udder health, and cow behavior, optimizing dairy production and reducing labor costs. Future trends forecast widespread adoption of AI-powered milking robots that enhance productivity, ensure hygienic conditions, and promote sustainable dairy farming practices.

Related Important Terms

Teat-End Health Assessment

Hand milking allows for gentle teat handling, reducing the risk of teat-end damage and promoting better teat-end keratin preservation, which is crucial for preventing mastitis. Machine milking systems, when properly calibrated, provide consistent vacuum levels and pulsation rates that minimize teat-end hyperkeratosis, but improper use can lead to increased teat-end lesions and inflammation.

Somatic Cell Count Reduction

Machine milking systems incorporate automated cleaning and precision teat stimulation, significantly reducing somatic cell counts by minimizing bacterial contamination compared to hand milking. Consistent milking pressure and hygiene protocols in mechanical milking also enhance udder health, leading to improved milk quality and lower incidences of mastitis.

Robotic Milking Systems

Robotic milking systems enhance dairy production by improving milking efficiency, ensuring consistent teat stimulation, and providing real-time health monitoring through automated sensors. These systems reduce labor costs and stress on animals, leading to increased milk yield and better overall herd management compared to traditional hand or machine milking methods.

Pulsation Ratio Optimization

Optimizing the pulsation ratio in machine milking enhances milk flow efficiency and animal comfort, crucial for maximizing dairy production. Hand milking lacks consistent pulsation control, leading to variable milk output and increased udder stress compared to precisely calibrated machine milking systems.

Quarter Milking Analysis

Quarter milking analysis reveals that machine milking offers more consistent milk yield and better udder health monitoring compared to hand milking. Automated systems facilitate precise milk flow measurement from each quarter, enhancing detection of mastitis and optimizing overall dairy production efficiency.

Vacuum Fluctuation Management

Vacuum fluctuation management is critical in both hand milking and machine milking systems to ensure consistent milk flow and prevent teat damage, with machine milking offering precise vacuum control through automated sensors and pulsation settings. Hand milking relies on manual rhythm and pressure, which can cause irregular vacuum levels, increasing the risk of teat tissue trauma and reduced milk yield compared to the stable vacuum environment maintained by modern milking machines.

Udder Stress Biomarkers

Hand milking in dairy production tends to cause lower levels of udder stress biomarkers such as cortisol and somatic cell count compared to machine milking, which can induce mechanical stress and microtrauma to the teat tissue. Monitoring these biomarkers helps optimize milking methods to enhance animal welfare and improve milk quality by reducing inflammation and infection risks.

On-farm Mastitis Detection Sensors

On-farm mastitis detection sensors integrated with machine milking systems provide real-time monitoring of somatic cell counts and milk conductivity, enabling early detection of infections and reducing the risk of herd-wide contamination. Hand milking lacks this precise sensor technology, making it less effective for timely mastitis diagnosis and intervention in large-scale dairy operations.

Milk Yield Consistency Index

The Milk Yield Consistency Index tends to be higher in machine milking due to precise timing and uniform extraction, reducing variability in daily milk output. Hand milking often results in fluctuating yields as it depends on the skill and endurance of the milker, impacting overall production stability.

Hygiene Protocol Automation

Hand milking relies heavily on manual hygiene practices, increasing the risk of contamination through inconsistent cleaning of hands and equipment. Machine milking systems automate hygiene protocols with integrated teat sanitizers and automated cluster cleaning cycles, significantly reducing bacterial load and enhancing milk safety in dairy production.

Hand Milking vs Machine Milking for Dairy Production Infographic

agridif.com

agridif.com