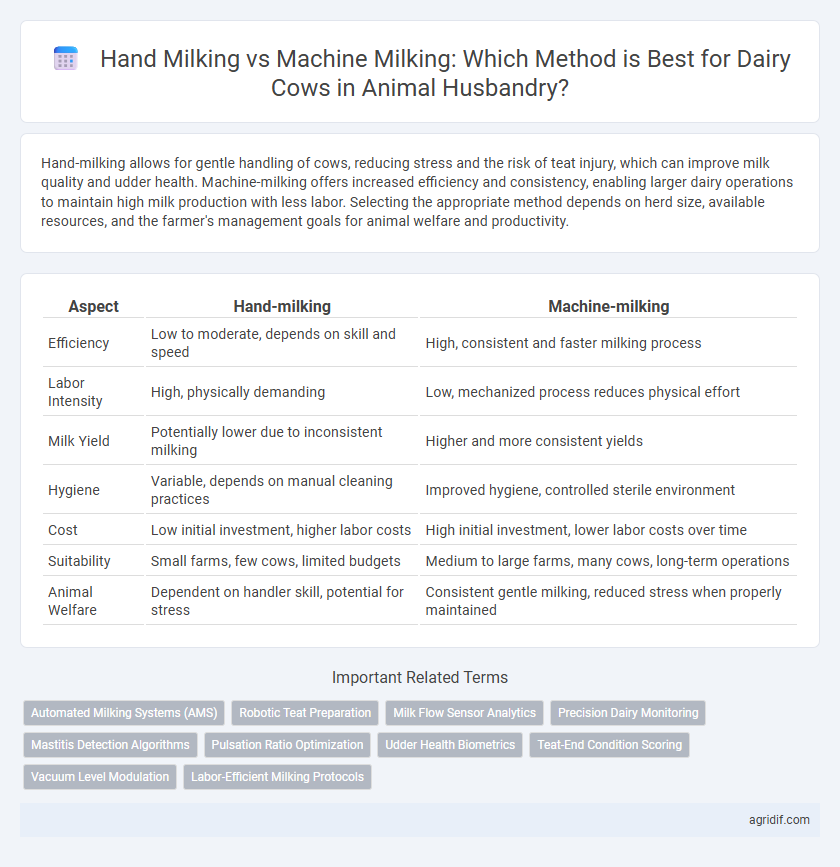

Hand-milking allows for gentle handling of cows, reducing stress and the risk of teat injury, which can improve milk quality and udder health. Machine-milking offers increased efficiency and consistency, enabling larger dairy operations to maintain high milk production with less labor. Selecting the appropriate method depends on herd size, available resources, and the farmer's management goals for animal welfare and productivity.

Table of Comparison

| Aspect | Hand-milking | Machine-milking |

|---|---|---|

| Efficiency | Low to moderate, depends on skill and speed | High, consistent and faster milking process |

| Labor Intensity | High, physically demanding | Low, mechanized process reduces physical effort |

| Milk Yield | Potentially lower due to inconsistent milking | Higher and more consistent yields |

| Hygiene | Variable, depends on manual cleaning practices | Improved hygiene, controlled sterile environment |

| Cost | Low initial investment, higher labor costs | High initial investment, lower labor costs over time |

| Suitability | Small farms, few cows, limited budgets | Medium to large farms, many cows, long-term operations |

| Animal Welfare | Dependent on handler skill, potential for stress | Consistent gentle milking, reduced stress when properly maintained |

Introduction to Milking Methods in Dairy Farming

Hand-milking and machine-milking are two fundamental methods used in dairy farming to extract milk from cows. Hand-milking requires manual skill and provides intimate control over the milking process, often preferred in small-scale or traditional farms. Machine-milking uses automated pumps that increase efficiency, consistency, and reduce labor, making it suitable for large-scale dairy operations.

Overview of Hand-Milking: Traditional Techniques

Hand-milking employs traditional techniques where the milker uses fingers and thumb to extract milk from cow udders, ensuring gentle stimulation and controlled flow. This method requires minimal equipment, making it ideal for small-scale farms and regions with limited access to advanced technology. Despite being labor-intensive, hand-milking promotes close animal-human interaction, potentially improving udder health through attentive handling.

Machine-Milking: Modern Innovations Explained

Machine-milking in dairy farming leverages advanced technologies such as automated milking systems (AMS) equipped with sensors and robotic arms to enhance efficiency and animal welfare. These innovations enable precise control over milking duration, udder health monitoring, and data collection for improved herd management. Integration of IoT and AI in machine-milking optimizes milk yield, reduces labor costs, and ensures consistent milk quality compared to traditional hand-milking methods.

Milk Yield Comparison: Hand vs. Machine

Machine-milking significantly increases milk yield compared to hand-milking due to consistent stimulation and efficient extraction. Studies show machine-milking can boost daily milk production by 30-50%, optimizing dairy farm productivity. Hand-milking often results in lower yield and variability, especially in large-scale operations where efficiency is critical.

Animal Health and Udder Hygiene Impacts

Hand-milking allows for gentle, personalized care that can reduce teat damage and promote udder health by minimizing contamination risks through direct observation and immediate cleaning. Machine-milking offers consistent milking pressure and efficiency but may increase the risk of teat-end hyperkeratosis and mastitis if equipment is improperly maintained or used. Implementing strict hygiene protocols and regular equipment inspection can mitigate health issues, ensuring both methods support optimal udder hygiene and animal welfare in dairy herds.

Labor Efficiency and Workforce Considerations

Hand-milking requires more time and physical effort, limiting the number of cows milked per worker, whereas machine-milking significantly increases labor efficiency by allowing a single operator to handle multiple cows simultaneously. Workforce considerations include the need for skilled labor to manage and maintain milking machines, reducing overall labor costs in large-scale dairy operations. Machine-milking also enhances hygiene and milk quality, which can lead to higher productivity and economic benefits for dairy farms.

Equipment Investment and Maintenance Costs

Hand-milking requires minimal equipment investment, typically just a clean bucket and a sturdy stool, resulting in negligible maintenance costs. Machine-milking involves significant upfront investment in milking machines, pipelines, and storage tanks, with ongoing expenses for regular servicing, parts replacement, and cleaning systems. For large-scale dairy operations, machine-milking offers efficiency despite higher maintenance costs, whereas hand-milking remains cost-effective for small herds with limited capital.

Quality Control: Milk Contamination and Safety

Hand-milking reduces the risk of mechanical contamination but relies heavily on stringent hygiene practices to prevent bacterial introduction, making consistent quality control challenging. Machine-milking systems, equipped with automated cleaning protocols and controlled suction, enhance milk safety by minimizing human contact and potential contamination sources. Implementing regular maintenance and monitoring of milking equipment is critical in both methods to ensure optimal milk quality and prevent pathogen proliferation.

Environmental and Sustainability Factors

Hand-milking cows requires minimal energy use and produces no greenhouse gas emissions from machinery, making it a low-impact method for small-scale farms focused on sustainability. Machine-milking, while energy-intensive, improves efficiency and allows for better hygiene control, reducing milk spoilage and waste, which supports environmentally responsible dairy production on larger scales. Balancing these methods depends on farm size and resource availability to optimize environmental outcomes and sustain long-term productivity.

Choosing the Right Milking Method for Your Farm

Hand-milking offers greater control and is ideal for small-scale farms or cows with irregular teat structure, promoting cow comfort and reducing mastitis risk. Machine-milking enhances efficiency and consistency on larger farms, increasing milk yield and reducing labor costs through automated pulsation and vacuum systems. Selecting the appropriate milking method depends on herd size, labor availability, initial investment capacity, and the farm's long-term production goals.

Related Important Terms

Automated Milking Systems (AMS)

Automated Milking Systems (AMS) enhance dairy farm efficiency by reducing labor costs and minimizing human error during the milking process, ensuring consistent milk quality and animal welfare. AMS technology incorporates advanced sensors and data analytics to monitor cow health, milk yield, and milking frequency, driving optimized herd management and increased productivity.

Robotic Teat Preparation

Robotic teat preparation systems enhance hygiene and stimulate milk letdown, reducing the risk of mastitis and increasing overall milking efficiency compared to traditional hand-milking. These automated systems integrate teat cleaning, disinfecting, and pre-milking massage, optimizing udder health and milk yield in machine-milking operations.

Milk Flow Sensor Analytics

Milk flow sensor analytics enhance machine-milking efficiency by providing real-time data on milk yield, flow rate, and cow health indicators, enabling timely interventions to optimize production and animal welfare. Hand-milking lacks this precision technology, resulting in lower data accuracy and reduced potential for monitoring udder health and detecting mastitis early.

Precision Dairy Monitoring

Hand-milking offers direct tactile feedback that allows farmers to detect abnormalities in udder health, but machine-milking integrated with precision dairy monitoring systems provides continuous real-time data on milk yield, cow behavior, and health metrics, enhancing herd management efficiency. Automated sensors embedded in milking machines track somatic cell counts and milking speed, facilitating early detection of mastitis and optimizing milk production through data-driven interventions.

Mastitis Detection Algorithms

Hand-milking allows farmers to detect early signs of mastitis through tactile sensitivity and visual inspection, enhancing timely intervention compared to machine-milking. Mastitis detection algorithms integrated into automated milking systems utilize sensor data like electrical conductivity and somatic cell count to identify infections promptly, improving herd health management.

Pulsation Ratio Optimization

Optimizing the pulsation ratio in machine-milking enhances milk extraction efficiency and udder health by mimicking the natural suckling rhythm of calves, reducing teat-end stress and preventing mastitis. Hand-milking lacks consistency in pulsation timing, leading to variable milk flow and potential discomfort, whereas machine-milking with precise pulsation control ensures uniform milking and improved animal welfare.

Udder Health Biometrics

Hand-milking offers gentle stimulation and reduces teat-end damage, promoting better udder health biometrics such as lower somatic cell counts and minimal teat edema. In contrast, machine-milking, while efficient for large herds, can increase the risk of teat-end hyperkeratosis and higher somatic cell counts if not properly calibrated and maintained.

Teat-End Condition Scoring

Hand-milking preserves teat-end integrity with lower risk of hyperkeratosis, promoting optimal udder health, while machine-milking often necessitates regular teat-end condition scoring to prevent tissue damage caused by vacuum pressure. Precise teat-end scoring using standardized scales aids in monitoring the effects of milking methods, enabling adjustments to machine settings and milking routines to minimize teat-end lesions and ensure animal welfare.

Vacuum Level Modulation

Vacuum level modulation in machine-milking optimizes milk flow and preserves teat health by adjusting suction intensity to mimick natural milking rhythms, reducing the risk of teat tissue damage compared to constant pressure systems. Hand-milking provides gentle, manual control over vacuum pressure but lacks the efficiency and consistent modulation achievable through automated vacuum-level adjustments in modern milking machines.

Labor-Efficient Milking Protocols

Hand-milking requires significant manual labor and time, making it less efficient for large-scale dairy operations, while machine-milking systems significantly reduce labor intensity and increase milking speed, supporting higher herd productivity. Investing in automated milking machines enhances labor efficiency by enabling simultaneous milking of multiple cows and reducing physical strain on workers, thereby optimizing overall milk yield and operational workflow.

Hand-milking vs Machine-milking for Milking Cows Infographic

agridif.com

agridif.com