Manual harvesting allows for selective picking and reduces crop damage, ensuring higher quality produce, especially for delicate fruits and vegetables. Mechanical harvesting significantly increases efficiency and reduces labor costs but may cause more bruising and is less precise in uneven terrains. Choosing the optimal harvesting method depends on crop type, scale of production, and cost considerations.

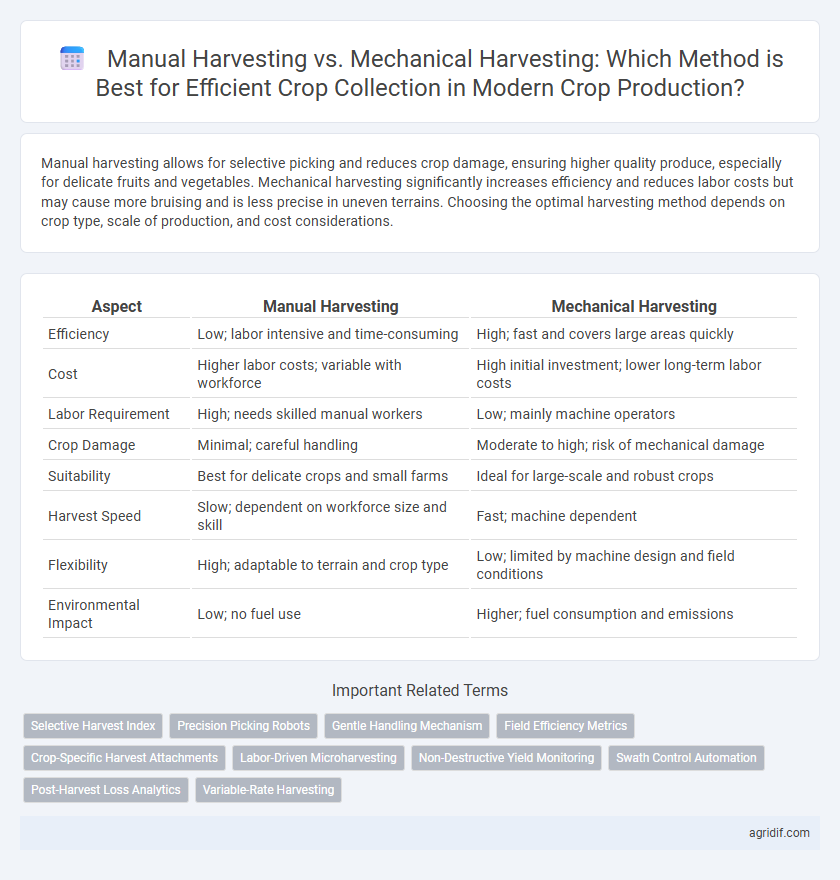

Table of Comparison

| Aspect | Manual Harvesting | Mechanical Harvesting |

|---|---|---|

| Efficiency | Low; labor intensive and time-consuming | High; fast and covers large areas quickly |

| Cost | Higher labor costs; variable with workforce | High initial investment; lower long-term labor costs |

| Labor Requirement | High; needs skilled manual workers | Low; mainly machine operators |

| Crop Damage | Minimal; careful handling | Moderate to high; risk of mechanical damage |

| Suitability | Best for delicate crops and small farms | Ideal for large-scale and robust crops |

| Harvest Speed | Slow; dependent on workforce size and skill | Fast; machine dependent |

| Flexibility | High; adaptable to terrain and crop type | Low; limited by machine design and field conditions |

| Environmental Impact | Low; no fuel use | Higher; fuel consumption and emissions |

Introduction to Crop Harvesting Methods

Manual harvesting involves labor-intensive collection of crops by hand, ensuring precision and minimal damage, ideal for delicate produce such as fruits and vegetables. Mechanical harvesting employs machines like combines and harvesters to rapidly gather crops on a large scale, significantly increasing efficiency for grains, corn, and soybeans. Choosing between these methods depends on factors such as crop type, field size, labor availability, and harvest timing to balance cost-effectiveness and crop quality.

Overview of Manual Harvesting Techniques

Manual harvesting techniques involve handpicking crops using basic tools such as sickles, knives, or shears, allowing precise selection and minimizing crop damage. These methods are highly labor-intensive, suitable for small-scale farms and delicate crops like fruits and vegetables that require careful handling. Despite lower efficiency compared to mechanical harvesters, manual techniques offer flexibility in uneven terrains and complex plant structures.

Mechanical Harvesting: Tools and Technologies

Mechanical harvesting employs advanced machinery such as combine harvesters, cotton pickers, and forage harvesters to efficiently collect crops while minimizing labor costs and time. These tools incorporate technologies like GPS guidance, automated controls, and crop sensors to enhance precision and reduce crop damage during collection. Innovations in mechanical harvesting contribute to increased productivity, scalability, and sustainability in modern agriculture.

Efficiency Comparison: Manual vs Mechanical Harvesting

Mechanical harvesting significantly increases efficiency by enabling rapid crop collection over large areas, reducing labor costs and time compared to manual harvesting. Manual harvesting, while labor-intensive and slower, offers precision in selecting ripe produce, minimizing damage in delicate crops like fruits and vegetables. Advances in mechanical harvesters, such as GPS-guided systems and automation, further optimize productivity and operational efficiency in large-scale crop production.

Labor Requirements and Workforce Implications

Manual harvesting demands intensive labor input, requiring a large, skilled workforce to efficiently pick crops, which can drive up labor costs and increase reliance on seasonal workers. Mechanical harvesting significantly reduces labor requirements by utilizing machines capable of harvesting large areas quickly, lowering overall workforce needs but increasing initial capital expenditure and maintenance costs. The shift from manual to mechanical harvesting impacts rural employment patterns, potentially reducing job opportunities while improving productivity and consistency in crop collection.

Harvest Quality and Crop Loss Considerations

Manual harvesting ensures higher harvest quality by allowing precise selection and gentle handling of crops, reducing damage and preserving freshness. Mechanical harvesting increases efficiency but often results in greater crop loss and bruising due to less selective and more forceful collection methods. Careful evaluation of crop type and market standards is essential to balance quality preservation against harvest speed and cost.

Economic Analysis of Harvesting Methods

Manual harvesting requires significant labor costs and longer operation times, leading to higher overall expenses compared to mechanical harvesting. Mechanical harvesting offers increased efficiency and reduced labor dependency but demands substantial initial investment and maintenance costs. Economic analysis shows that mechanical methods become more cost-effective at larger scales of crop production, especially for high-yield and labor-intensive crops like wheat and corn.

Environmental Impact: Manual vs Mechanical Approaches

Manual harvesting minimizes soil compaction and reduces fuel consumption, leading to lower carbon emissions compared to mechanical harvesting. Mechanical harvesters often disturb soil structure, increase greenhouse gas emissions, and contribute to higher energy use. Choosing manual methods supports sustainable agriculture by preserving soil health and reducing environmental degradation.

Suitability for Different Crop Types

Manual harvesting excels in delicate crops like fruits, vegetables, and specialty herbs that require careful handling to prevent damage and ensure quality. Mechanical harvesting is best suited for large-scale grain crops such as wheat, corn, and soybeans, where speed and efficiency are critical to meet harvesting windows. Crop characteristics like plant height, density, and fragility heavily influence the choice between manual and mechanical methods for optimal yield and minimal loss.

Future Trends in Crop Harvesting Technologies

Future trends in crop harvesting technologies emphasize increasing automation and precision, with mechanical harvesting systems integrating AI-driven sensors and robotics to enhance efficiency and reduce labor costs. Advances in drone technology and GPS-guided machinery enable real-time monitoring and targeted crop collection, optimizing yield quality and minimizing waste. Innovations in biodegradable sensor networks and IoT connectivity promise to revolutionize crop management, ensuring sustainable and scalable harvesting solutions.

Related Important Terms

Selective Harvest Index

Manual harvesting allows for precise selective harvest index by enabling workers to pick only ripe or high-quality crops, minimizing damage and waste. Mechanical harvesting offers high efficiency but often sacrifices selectivity, leading to potential losses in crop quality and increased post-harvest sorting requirements.

Precision Picking Robots

Precision picking robots revolutionize manual harvesting by using advanced sensors and AI to identify and collect ripe crops with minimal damage, significantly increasing efficiency compared to traditional handpicking. These robots reduce labor costs, improve crop yield quality, and enable precise harvesting schedules tailored to specific plant maturity stages.

Gentle Handling Mechanism

Manual harvesting ensures gentle handling of crops by minimizing bruising and damage through careful handpicking, preserving quality especially in delicate fruits and vegetables. Mechanical harvesting, while faster and more efficient, requires advanced gentle handling mechanisms like cushioned conveyors and adjustable picking speeds to reduce crop damage during collection.

Field Efficiency Metrics

Manual harvesting typically results in lower field efficiency, with average crop collection rates around 0.5 to 1 ton per hectare per hour, heavily influenced by labor skill and crop type. In contrast, mechanical harvesting can achieve efficiency rates exceeding 5 tons per hectare per hour, significantly reducing labor costs and increasing the speed of crop collection while maintaining consistent quality.

Crop-Specific Harvest Attachments

Manual harvesting remains essential for delicate crops like grapes and strawberries, where precision and minimal damage are crucial; specialized tools such as pruning shears and hand rakes are commonly used to ensure optimal quality. Mechanical harvesting utilizes crop-specific attachments like combine headers for grains and pickers for cotton, enhancing efficiency but requiring adjustments to reduce crop loss and maintain product integrity.

Labor-Driven Microharvesting

Labor-driven microharvesting in crop production involves manual harvesting techniques that enable precise selection and minimal crop damage, particularly beneficial for delicate or specialty crops. While mechanical harvesting increases efficiency and scale, manual methods offer superior control and adaptability in diverse field conditions, supporting crop quality and niche markets.

Non-Destructive Yield Monitoring

Manual harvesting preserves crop integrity by allowing selective picking, which minimizes damage and enables precise non-destructive yield monitoring through direct visual assessment and sampling. Mechanical harvesting increases efficiency yet risks crop bruising and loss, challenging accurate yield estimation and requiring advanced sensor technology to achieve reliable non-destructive data collection.

Swath Control Automation

Swath control automation in mechanical harvesting enhances efficiency by precisely managing crop windrow placement, minimizing overlap and crop loss compared to manual harvesting methods. Advanced sensor technology and GPS integration ensure consistent swath width and optimal field coverage, increasing overall yield and reducing labor costs.

Post-Harvest Loss Analytics

Manual harvesting often results in lower post-harvest losses for delicate crops due to careful handling, but it is labor-intensive and slower compared to mechanical harvesting, which can increase throughput yet cause higher damage rates and losses due to machine inefficiencies. Post-harvest loss analytics reveal that optimizing mechanical harvester settings and maintenance can significantly reduce crop damage and improve overall yield quality in large-scale production systems.

Variable-Rate Harvesting

Manual harvesting allows precise crop collection by selectively picking ripe plants, but it is labor-intensive and time-consuming. Mechanical harvesting with variable-rate technology adjusts machinery speed and settings based on crop yield data, maximizing efficiency and reducing grain loss during collection.

Manual Harvesting vs Mechanical Harvesting for Crop Collection Infographic

agridif.com

agridif.com