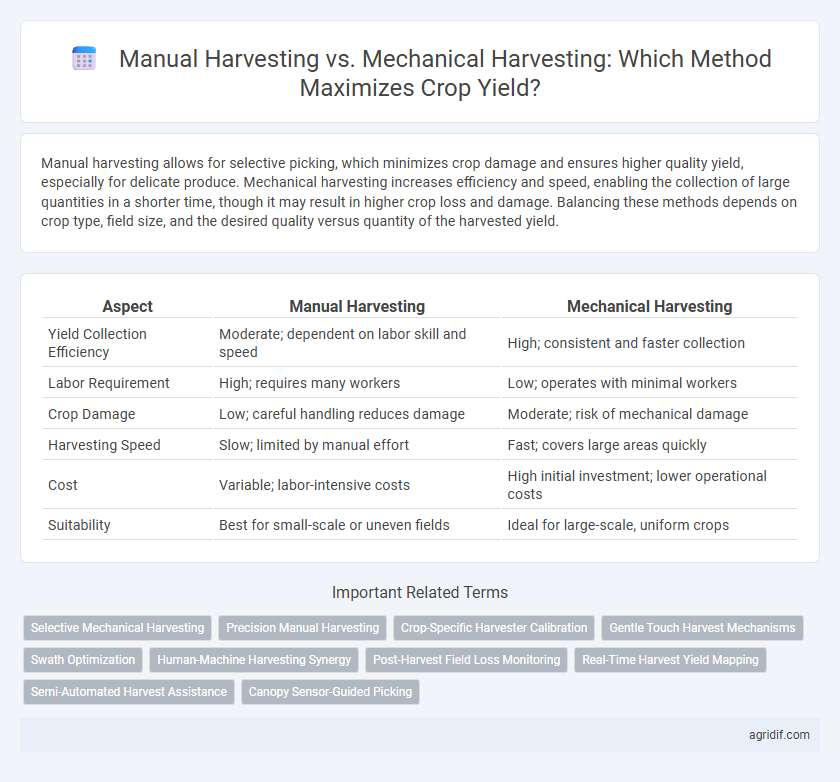

Manual harvesting allows for selective picking, which minimizes crop damage and ensures higher quality yield, especially for delicate produce. Mechanical harvesting increases efficiency and speed, enabling the collection of large quantities in a shorter time, though it may result in higher crop loss and damage. Balancing these methods depends on crop type, field size, and the desired quality versus quantity of the harvested yield.

Table of Comparison

| Aspect | Manual Harvesting | Mechanical Harvesting |

|---|---|---|

| Yield Collection Efficiency | Moderate; dependent on labor skill and speed | High; consistent and faster collection |

| Labor Requirement | High; requires many workers | Low; operates with minimal workers |

| Crop Damage | Low; careful handling reduces damage | Moderate; risk of mechanical damage |

| Harvesting Speed | Slow; limited by manual effort | Fast; covers large areas quickly |

| Cost | Variable; labor-intensive costs | High initial investment; lower operational costs |

| Suitability | Best for small-scale or uneven fields | Ideal for large-scale, uniform crops |

Introduction to Crop Harvesting Methods

Manual harvesting involves handpicking crops, which allows for selective harvesting and minimal damage to plants, making it suitable for delicate or high-value crops. Mechanical harvesting uses machinery such as combine harvesters to efficiently collect large-scale yields, significantly reducing labor costs and time. The choice between manual and mechanical methods depends on crop type, farm size, and economic factors influencing overall productivity and yield quality.

Overview of Manual Harvesting Techniques

Manual harvesting techniques involve handpicking, cutting, or gathering crops using simple tools such as sickles, knives, and baskets, allowing for selective harvesting and minimal crop damage. This method provides precise yield collection, especially suitable for delicate fruits and vegetables, improving product quality and reducing post-harvest losses. Labor-intensive and time-consuming, manual harvesting remains predominant in small-scale farms and regions with limited access to mechanized equipment.

Advances in Mechanical Harvesting Technology

Advances in mechanical harvesting technology have significantly increased efficiency and yield collection in crop production by reducing labor costs and minimizing crop losses. Innovations such as precision-guided harvesters equipped with GPS and sensor-based sorting systems enable selective picking and real-time quality assessment, enhancing overall productivity. These technologies facilitate faster processing and greater scalability compared to traditional manual harvesting, supporting large-scale agricultural operations and improving crop output consistency.

Labor Requirements: Manual vs Mechanical Harvesting

Manual harvesting demands significant labor input, requiring numerous workers to pick crops by hand, which increases labor costs and time. Mechanical harvesting drastically reduces labor requirements by utilizing advanced machinery capable of efficiently collecting high volumes of crops, minimizing human involvement. This shift not only accelerates the harvesting process but also enhances productivity and addresses labor shortages in large-scale crop production.

Impact on Crop Yield and Quality

Manual harvesting allows for selective picking, minimizing crop damage and preserving quality, which often results in higher market value despite being labor-intensive. Mechanical harvesting increases efficiency and scale but may cause more physical damage to crops, potentially reducing quality and leading to greater post-harvest losses. The choice between methods significantly influences overall yield collection, balancing speed and precision to optimize crop output and product integrity.

Cost Analysis: Manual Versus Mechanical Harvesting

Manual harvesting incurs higher labor costs and longer harvest times, impacting overall profitability, especially for large-scale farms. Mechanical harvesting requires significant upfront investment in machinery but reduces labor expenses and accelerates yield collection, improving efficiency and cost-effectiveness over time. Optimizing the balance between labor costs and machinery expenses is crucial for maximizing economic returns in crop production.

Environmental Considerations in Harvesting Choices

Manual harvesting minimizes soil compaction and preserves biodiversity due to selective crop removal, reducing environmental degradation. Mechanical harvesting increases efficiency but often leads to higher energy consumption, greenhouse gas emissions, and greater soil disturbance. Choosing between methods depends on balancing yield optimization with sustainability goals and farm-scale environmental impact.

Suitability for Different Crop Types

Manual harvesting offers precision and is ideal for delicate crops like fruits and vegetables that require careful handling to prevent damage. Mechanical harvesting suits large-scale grain crops such as wheat, corn, and soybeans, enabling faster collection and increased efficiency. Crop characteristics, field size, and labor availability determine the optimal harvesting method for maximizing yield collection.

Post-Harvest Handling and Efficiency

Manual harvesting allows for selective crop picking, minimizing damage and preserving quality during post-harvest handling. Mechanical harvesting significantly boosts efficiency by reducing labor time and accelerating yield collection, though it may increase the risk of bruising and spoilage. Integrating advanced sorting and cleaning technologies after mechanical harvesting enhances overall crop quality and storage longevity.

Future Trends in Harvesting Technologies

Emerging trends in harvesting technologies emphasize the integration of AI-powered robotics and drone-based systems to enhance efficiency and precision in yield collection. Advances in sensor technology and machine learning enable real-time crop health monitoring and selective harvesting, reducing waste and maximizing output. Future harvesting solutions aim to balance cost-effectiveness with sustainability by minimizing labor requirements while improving crop quality and overall productivity.

Related Important Terms

Selective Mechanical Harvesting

Selective mechanical harvesting enhances yield collection by precisely targeting mature crops, reducing damage to plants and minimizing unripe produce collection. This method increases efficiency and preserves crop quality compared to traditional manual harvesting or broad mechanical approaches, optimizing overall farm productivity.

Precision Manual Harvesting

Precision manual harvesting allows for selective picking of ripe crops, significantly reducing damage and loss compared to broad mechanical harvesting methods. This targeted approach enhances overall yield quality and maximizes the market value of harvested produce by carefully handling each plant at optimal maturity.

Crop-Specific Harvester Calibration

Manual harvesting allows precise crop-specific handling, reducing damage and maintaining quality, but is labor-intensive and slower. Mechanical harvesting requires careful calibration of harvesters to match crop characteristics such as size, moisture content, and density to optimize yield collection and minimize losses.

Gentle Touch Harvest Mechanisms

Manual harvesting ensures minimal crop damage through gentle touch techniques that preserve the integrity of delicate fruits and vegetables, leading to higher-quality yield collection. Mechanical harvesting with advanced gentle touch mechanisms reduces bruising and losses, improving efficiency while maintaining crop quality comparable to hand-picking.

Swath Optimization

Swath optimization in manual harvesting allows precise control over crop placement, reducing grain losses and enhancing yield quality through selective cutting and careful bundling. Mechanical harvesting achieves higher efficiency by automating swath width and overlap adjustments, maximizing field coverage and minimizing unharvested areas, thereby increasing overall yield collection.

Human-Machine Harvesting Synergy

Manual harvesting allows for precise crop selection and minimizes damage to delicate produce, while mechanical harvesting significantly increases efficiency and reduces labor costs on large-scale farms. Combining human expertise with advanced machinery optimizes yield collection by balancing accuracy and speed, enhancing overall productivity in crop production.

Post-Harvest Field Loss Monitoring

Manual harvesting allows for selective crop collection, reducing initial field damage but often causes inconsistent post-harvest losses due to human error and slower processing. Mechanical harvesting increases efficiency and uniformity in yield collection but may result in higher post-harvest field losses through grain shattering and incomplete crop retrieval, necessitating advanced loss monitoring technologies to optimize overall productivity.

Real-Time Harvest Yield Mapping

Real-time harvest yield mapping enhances manual harvesting by allowing precise tracking of crop yields at specific locations, improving decision-making and field management. Mechanical harvesting integrates advanced yield monitors with GPS technology to provide continuous, high-resolution data, optimizing harvest efficiency and enabling accurate yield variability analysis across large fields.

Semi-Automated Harvest Assistance

Semi-automated harvest assistance integrates manual dexterity with mechanical efficiency, enhancing yield collection by reducing labor intensity while maintaining crop integrity. This hybrid approach optimizes harvesting speed and accuracy in diverse terrains, leading to higher productivity and minimized post-harvest losses compared to purely manual or fully mechanical methods.

Canopy Sensor-Guided Picking

Canopy sensor-guided picking enhances yield accuracy by enabling precise identification of ripe crops, reducing crop loss compared to manual harvesting which relies heavily on labor skill and speed. Mechanical harvesting integrated with canopy sensors optimizes efficiency and uniformity, improving overall crop production while minimizing human error.

Manual Harvesting vs Mechanical Harvesting for Yield Collection Infographic

agridif.com

agridif.com