Conventional milking methods rely on manual labor, requiring more time and physical effort but offering direct animal interaction and control. Robotic milking systems automate the milking process, improving efficiency and consistency while reducing labor costs and stress on dairy cows. Both methods impact milk quality and farm management differently, with robotic technology increasingly favored for large-scale operations.

Table of Comparison

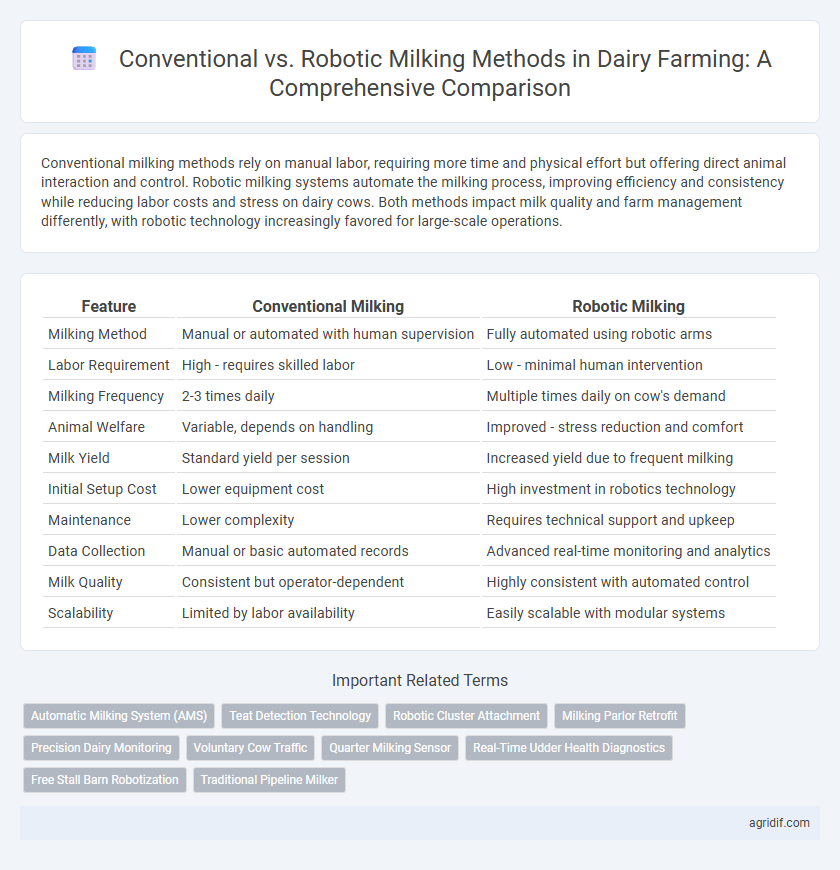

| Feature | Conventional Milking | Robotic Milking |

|---|---|---|

| Milking Method | Manual or automated with human supervision | Fully automated using robotic arms |

| Labor Requirement | High - requires skilled labor | Low - minimal human intervention |

| Milking Frequency | 2-3 times daily | Multiple times daily on cow's demand |

| Animal Welfare | Variable, depends on handling | Improved - stress reduction and comfort |

| Milk Yield | Standard yield per session | Increased yield due to frequent milking |

| Initial Setup Cost | Lower equipment cost | High investment in robotics technology |

| Maintenance | Lower complexity | Requires technical support and upkeep |

| Data Collection | Manual or basic automated records | Advanced real-time monitoring and analytics |

| Milk Quality | Consistent but operator-dependent | Highly consistent with automated control |

| Scalability | Limited by labor availability | Easily scalable with modular systems |

Overview of Conventional and Robotic Milking Methods

Conventional milking methods rely on manual labor using milking machines operated by farmers, requiring scheduled milking times and consistent human intervention to ensure animal welfare and milk hygiene. Robotic milking systems utilize automated technology with sensors and artificial intelligence to identify individual cows, monitor health, and allow cows to be milked voluntarily, improving efficiency and reducing labor costs. Both methods aim to maximize milk production and quality, but robotic milking offers enhanced data collection and flexibility in herd management.

Historical Development of Milking Techniques

Milking techniques have evolved from manual hand milking to conventional mechanical systems introduced in the late 19th century, which significantly increased efficiency on dairy farms. The development of robotic milking systems began in the 1990s, integrating advanced automation and sensor technology to optimize milk yield and animal health monitoring. This shift has transformed dairy farming by enhancing precision and reducing labor demands while maintaining milk quality.

Installation and Infrastructure Requirements

Conventional milking systems require extensive infrastructure, including large milking parlors with manual stalls and piping for milk transport. Robotic milking systems demand high initial investment in automated machinery, sensor integration, and reliable power supply, along with modifications to barn layouts to accommodate robotic units. Both methods depend on stable water sources and waste management setups, but robotic systems emphasize advanced data connectivity and maintenance facilities to ensure continuous operation.

Labor Efficiency and Management

Robotic milking systems significantly enhance labor efficiency by automating the milking process, reducing the need for manual labor and allowing farmers to manage larger herds with fewer workers. Conventional milking requires consistent manual labor, demanding scheduled milking times and increasing labor costs and management complexity. Robotic technology also provides real-time data monitoring, improving herd health management and operational decision-making, which is less feasible with traditional methods.

Animal Welfare and Cow Comfort

Robotic milking systems enhance animal welfare by allowing cows to be milked on demand, reducing stress and promoting natural behaviors. Conventional milking methods often involve fixed schedules and more human handling, which can increase discomfort and anxiety in cows. Improved cow comfort in robotic systems leads to better udder health and higher milk quality, contributing to overall herd well-being.

Milking Frequency and Yield Comparisons

Robotic milking systems enable cows to be milked up to three times per day, increasing milking frequency compared to conventional methods that typically milk cows twice daily. Studies show robotic milking can boost average milk yield by 5-15% due to more frequent milking and reduced cow stress. Conventional milking requires fixed schedules, potentially limiting output, while robotics offer flexible milking intervals tailored to individual cow needs, enhancing overall productivity.

Economic Investment and Operational Costs

Conventional milking systems require lower upfront capital investment but incur higher ongoing labor costs and maintenance expenses compared to robotic milking systems. Robotic milking technology involves significant initial expenditure, often exceeding $150,000 per unit, but reduces labor costs by automating the milking process and improving herd management efficiency. Over time, robotic systems can provide better economic returns through increased milk yield and reduced labor intensity, despite higher initial investment and maintenance costs.

Milk Quality and Hygiene Standards

Conventional milking methods rely on manual labor and basic machinery, which can introduce variability in hygiene standards and increase the risk of contamination, potentially affecting milk quality. Robotic milking systems use automated cleaning protocols and sensors to consistently maintain optimal hygiene, resulting in improved milk quality with reduced bacterial counts and minimal somatic cell levels. Enhanced teat preparation and post-milking teat disinfection in robotic systems ensure superior udder health and higher standards of milk hygiene compared to conventional milking practices.

Data Management and Technology Integration

Robotic milking systems leverage advanced data management platforms to monitor cow health, milk yield, and feed efficiency in real-time, enhancing precision and decision-making on dairy farms. Conventional milking methods rely heavily on manual recording and limited automation, resulting in less comprehensive data collection and slower response to animal needs. Integration of IoT sensors and machine learning in robotic systems allows seamless synchronization with farm management software, optimizing operational efficiency and animal welfare.

Environmental and Sustainability Impact

Conventional milking systems typically require more labor and energy, leading to higher greenhouse gas emissions and water usage compared to robotic milking systems. Robotic milking enhances sustainability by optimizing cow health and feed efficiency, reducing waste and nutrient runoff, and allowing more precise resource management. Studies show that robotic systems can lower the carbon footprint of dairy farms by improving milk yield per cow while minimizing environmental impacts.

Related Important Terms

Automatic Milking System (AMS)

Automatic Milking Systems (AMS) enhance dairy farming efficiency by using robotics to independently milk cows, reducing labor costs and improving animal welfare through consistent milking routines. Compared to conventional milking methods, AMS offers real-time data monitoring, optimized milk yield, and lower instances of mastitis, driving both productivity and herd health.

Teat Detection Technology

Conventional milking methods rely on manual teat detection, often resulting in inconsistent milking and increased labor costs, while robotic milking systems use advanced teat detection technology with machine vision and sensors to ensure precise and efficient milking. This technology improves milking speed, reduces udder health issues, and enhances overall dairy farm productivity through automated, real-time monitoring and adjustment.

Robotic Cluster Attachment

Robotic cluster attachment technology in dairy farming enhances milking efficiency by automating teat detection and attachment, reducing labor costs and improving animal welfare through consistent milking routines. Conventional milking methods rely on manual cluster attachment, which is labor-intensive and prone to variability in milking times and animal stress levels.

Milking Parlor Retrofit

Milking parlor retrofit in dairy farming upgrades conventional systems by integrating robotic milking technology, enhancing efficiency and animal welfare through automated milking processes and real-time monitoring. This retrofit reduces labor costs and increases milking frequency, improving milk yield and quality compared to traditional manual or semi-automated parlors.

Precision Dairy Monitoring

Conventional milking relies on manual labor and scheduled routines, limiting real-time herd data collection, whereas robotic milking systems integrate precision dairy monitoring technologies that continuously track cow health, milk yield, and udder condition. This automation enhances data accuracy and early disease detection, leading to improved milk quality and optimized farm management decisions.

Voluntary Cow Traffic

Robotic milking systems enhance voluntary cow traffic by allowing cows to choose milking times, improving milk yield and cow welfare compared to conventional fixed-schedule milking. This technology leverages cow autonomy to increase milking frequency and reduce labor costs, optimizing overall dairy farm productivity.

Quarter Milking Sensor

Quarter milking sensors in robotic milking systems enable precise monitoring of milk yield and quality at the udder quarter level, enhancing udder health management and early detection of mastitis compared to conventional milking methods. These sensors improve milking efficiency by automatically adjusting milking parameters, reducing labor costs, and increasing overall herd productivity.

Real-Time Udder Health Diagnostics

Robotic milking systems provide real-time udder health diagnostics through integrated sensors that monitor milk conductivity, temperature, and somatic cell counts, enabling early detection of mastitis and improved herd health management. Conventional milking methods rely on periodic manual inspections and delayed laboratory results, often missing early signs of udder infections and leading to reduced milk quality.

Free Stall Barn Robotization

Free stall barn robotization in dairy farming enhances milking efficiency by allowing cows to be milked voluntarily, improving herd health monitoring, and reducing labor costs compared to conventional milking methods. This technology integrates automated milking systems within free stall barns, optimizing cow comfort and boosting milk yield through precise, real-time data collection and management.

Traditional Pipeline Milker

Traditional pipeline milkers in conventional dairy farming offer a cost-effective, reliable solution with established infrastructure and minimal technological complexity. However, they require significant manual labor and have limited real-time monitoring capabilities compared to advanced robotic milking systems.

Conventional vs Robotic for milking method Infographic

agridif.com

agridif.com