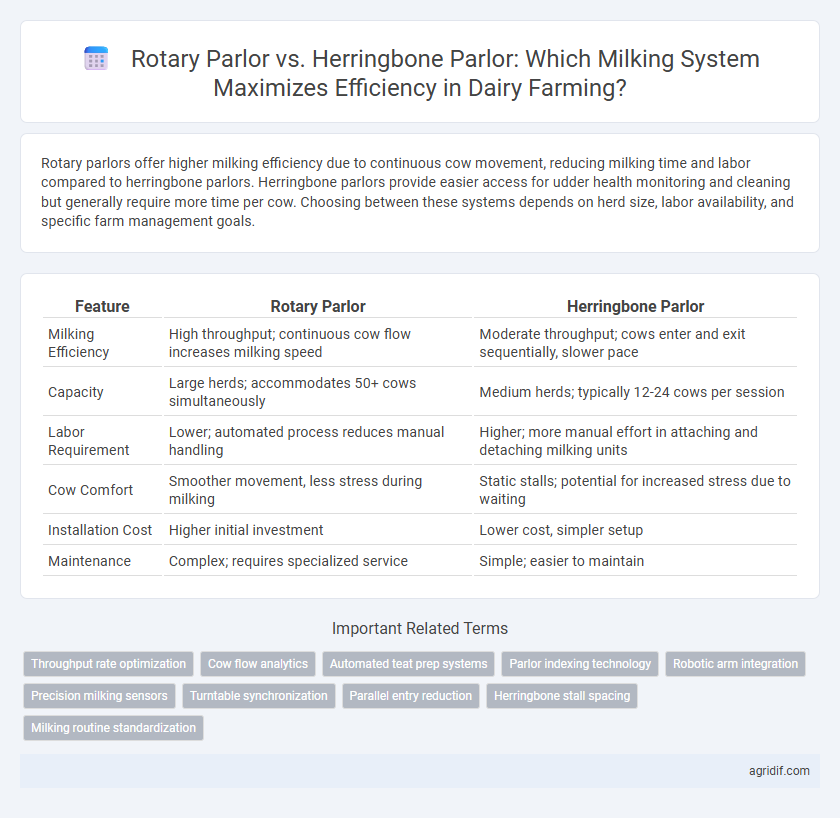

Rotary parlors offer higher milking efficiency due to continuous cow movement, reducing milking time and labor compared to herringbone parlors. Herringbone parlors provide easier access for udder health monitoring and cleaning but generally require more time per cow. Choosing between these systems depends on herd size, labor availability, and specific farm management goals.

Table of Comparison

| Feature | Rotary Parlor | Herringbone Parlor |

|---|---|---|

| Milking Efficiency | High throughput; continuous cow flow increases milking speed | Moderate throughput; cows enter and exit sequentially, slower pace |

| Capacity | Large herds; accommodates 50+ cows simultaneously | Medium herds; typically 12-24 cows per session |

| Labor Requirement | Lower; automated process reduces manual handling | Higher; more manual effort in attaching and detaching milking units |

| Cow Comfort | Smoother movement, less stress during milking | Static stalls; potential for increased stress due to waiting |

| Installation Cost | Higher initial investment | Lower cost, simpler setup |

| Maintenance | Complex; requires specialized service | Simple; easier to maintain |

Overview of Milking Parlor Systems

Rotary parlors offer continuous cow movement allowing high-throughput milking, processing up to 60-100 cows per hour, which significantly enhances efficiency in large-scale dairy operations. Herringbone parlors feature a fixed, angled stall layout with cows standing at a 45-60 degree angle, enabling easier access to udders but limiting throughput to around 30-60 cows per hour. Choosing between rotary and herringbone systems depends on herd size, labor availability, and desired milking speed, where rotary parlors excel in volume and flow optimization while herringbone parlors provide simplicity and cost-effectiveness.

Rotary Parlor: Design and Functionality

Rotary parlors feature a circular platform that continuously rotates, allowing multiple cows to be milked simultaneously, significantly increasing throughput compared to herringbone parlors. Their ergonomic design facilitates efficient cow movement and operator access, reducing milking time and labor costs. Advanced automation and sensors integrated into rotary systems enhance milk flow monitoring, herd management, and overall milking efficiency.

Herringbone Parlor: Design and Setup

Herringbone parlors feature a slanted stall design where cows stand at an angle, allowing simultaneous access to udder quarters for efficient milking. The setup typically includes a raised platform for operators, facilitating easy attachment of milking machines and reducing animal stress during the process. This design maximizes space utilization and enhances milking speed by enabling multiple cows to be milked side-by-side in a controlled environment.

Throughput Comparison: Rotary vs. Herringbone

Rotary parlors typically achieve higher milking throughput than herringbone parlors due to their continuous, circular operation allowing multiple cows to be milked simultaneously without interruption. Herringbone parlors operate in a linear fashion with cows entering and exiting sequentially, often resulting in longer cycle times and lower overall capacity. Farms seeking maximum efficiency often prefer rotary systems for their ability to handle larger herds with faster milking rates, optimizing daily labor and reducing bottlenecks.

Labor Efficiency in Rotary and Herringbone Parlors

Rotary parlors offer superior labor efficiency by enabling continuous milking with minimal operator movement, allowing one worker to manage multiple cows simultaneously. Herringbone parlors require more manual labor as cows enter and exit in batches, necessitating frequent attention to positioning and milking stages. The streamlined workflow of rotary systems reduces labor time per cow, increasing overall throughput on dairy farms.

Cow Comfort and Flow Management

Rotary parlors enhance milking efficiency by promoting continuous cow movement, reducing waiting times and stress, which improves overall cow comfort. The circular design allows for smoother flow management, minimizing disruptions and optimizing labor efficiency. Herringbone parlors offer a simpler setup but may cause longer pauses between cows, potentially increasing stress and reducing flow consistency compared to rotary systems.

Space and Infrastructure Requirements

Rotary parlors require a larger circular space with specialized infrastructure for efficient rotation and worker access, making them suitable for high-capacity dairy farms. Herringbone parlors demand less floor space in a linear layout, allowing easier integration into existing barns with simpler infrastructure needs. The choice impacts farm design, with rotary parlors necessitating more extensive investment in space optimization and mechanical systems compared to herringbone parlors.

Operational Costs: Rotary vs. Herringbone Parlors

Rotary parlors typically have higher upfront installation costs but offer lower long-term operational expenses due to faster cow throughput and reduced labor requirements. Herringbone parlors often incur lower initial investment but experience increased operational costs related to slower milking times and higher labor intensity. Optimizing operational costs involves evaluating herd size, labor availability, and milking frequency to determine the most cost-efficient parlor system.

Maintenance Demands and Downtime

Rotary parlors often require specialized maintenance due to their complex mechanical and electrical systems, which can lead to higher upkeep costs and extended downtime during repairs. In contrast, herringbone parlors have simpler designs with fewer moving parts, resulting in lower maintenance demands and quicker recovery times after maintenance. Efficient farm operations benefit from understanding that rotary parlors may increase milking capacity at the expense of more frequent and costly maintenance compared to the relatively low-maintenance, more reliable herringbone parlors.

Choosing the Right Parlor for Your Dairy Farm

Rotary parlors offer superior milking efficiency with continuous cow movement, reducing milking time per animal compared to herringbone parlors, which require cows to enter and exit individually. For large-scale dairy farms, rotary systems enhance throughput and labor productivity, while herringbone parlors remain cost-effective for smaller operations with lower herd sizes. Selecting the right parlor depends on herd size, labor availability, and budget constraints to optimize milk yield and operational efficiency.

Related Important Terms

Throughput rate optimization

Rotary parlors offer higher throughput rates by allowing continuous cow movement and simultaneous milking, significantly reducing idle time compared to herringbone parlors, which process cows in batches with intermittent pauses. Optimizing milking efficiency in dairy farming relies on deploying rotary systems that maximize herd throughput and minimize labor bottlenecks.

Cow flow analytics

Rotary parlors enable continuous cow movement, significantly improving milking efficiency through optimized cow flow and reduced idle time, whereas herringbone parlors often experience bottlenecks due to batch processing and slower cow turnover. Advanced cow flow analytics reveal that rotary systems maintain consistent throughput rates, enhancing overall milking speed and cow comfort compared to the intermittent flow characteristic of herringbone designs.

Automated teat prep systems

Rotary parlors with automated teat prep systems enhance milking efficiency by ensuring consistent teat cleaning and stimulation, reducing milking time per cow compared to herringbone parlors, which often rely on manual or less integrated preparation methods. Automated teat prep in rotary systems improves udder health through precise sanitizer application and uniform teat drying, leading to higher milk quality and reduced mastitis incidence.

Parlor indexing technology

Rotary parlors utilize advanced parlor indexing technology that enables continuous, smooth rotation of cows, significantly increasing milking efficiency by reducing idle time during unit attachment and detachment. Herringbone parlors, while effective, rely on manual or semi-automated indexing, resulting in longer transition times and lower throughput compared to the streamlined process of rotary systems.

Robotic arm integration

Rotary parlors offer enhanced milking efficiency through continuous cow rotation and seamless integration with robotic arms, enabling precision teat cleaning and automated milking processes that reduce labor and increase throughput. In contrast, herringbone parlors, with their stationary cow positioning, face limitations in robotic arm integration, resulting in slower milking cycles and less automation adaptability.

Precision milking sensors

Rotary parlors equipped with precision milking sensors enable continuous, real-time monitoring of each cow's health and milk yield, significantly enhancing milking efficiency compared to herringbone parlors. Herringbone systems, while effective, typically lack the advanced sensor integration found in rotary parlors, resulting in slower throughput and less precise individual cow data collection.

Turntable synchronization

Rotary parlors achieve higher milking efficiency through precise turntable synchronization, enabling continuous, simultaneous milking of multiple cows and reducing idle time between clusters. In contrast, herringbone parlors lack this synchronized movement, leading to sequential milking that extends overall milking duration and lowers throughput.

Parallel entry reduction

Rotary parlors significantly enhance milking efficiency by enabling continuous parallel entry and exit of cows, reducing bottlenecks common in herringbone parlors where cows enter and exit sequentially at an angle. This parallel movement in rotary systems minimizes cow handling time and increases throughput compared to the slower, angled entry and exit patterns of herringbone designs.

Herringbone stall spacing

Herringbone parlors feature wider stall spacing compared to rotary parlors, allowing easier cow movement and access for milking operators, which can enhance milking efficiency in smaller herds. While rotary parlors offer continuous cow flow suited for large-scale operations, the 45-55 degree angle and ample stall width in herringbone designs reduce cow stress and milking time, optimizing udder access and cleaning procedures.

Milking routine standardization

Rotary parlors enable high-throughput milking with consistent cow movement, promoting standardized milking routines and reducing handling variability. Herringbone parlors offer easier access for operators but often result in longer milking times and less uniform milking intervals, impacting efficiency.

Rotary parlor vs herringbone parlor for milking efficiency Infographic

agridif.com

agridif.com