Pivot irrigation systems provide efficient water distribution with a fixed central point, enabling uniform coverage ideal for large-scale grain production. Linear move irrigation offers flexibility by moving laterally across the field, better suited for irregularly shaped or expansive plots. Both systems optimize water use, but pivot irrigation typically reduces labor and energy costs compared to linear moves.

Table of Comparison

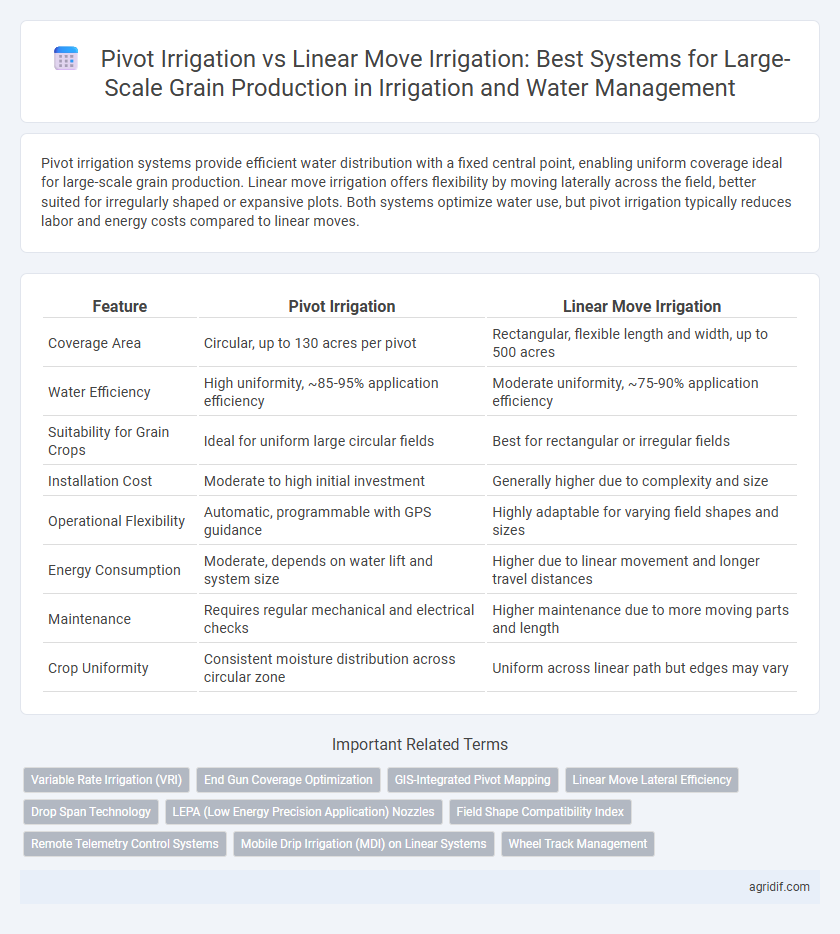

| Feature | Pivot Irrigation | Linear Move Irrigation |

|---|---|---|

| Coverage Area | Circular, up to 130 acres per pivot | Rectangular, flexible length and width, up to 500 acres |

| Water Efficiency | High uniformity, ~85-95% application efficiency | Moderate uniformity, ~75-90% application efficiency |

| Suitability for Grain Crops | Ideal for uniform large circular fields | Best for rectangular or irregular fields |

| Installation Cost | Moderate to high initial investment | Generally higher due to complexity and size |

| Operational Flexibility | Automatic, programmable with GPS guidance | Highly adaptable for varying field shapes and sizes |

| Energy Consumption | Moderate, depends on water lift and system size | Higher due to linear movement and longer travel distances |

| Maintenance | Requires regular mechanical and electrical checks | Higher maintenance due to more moving parts and length |

| Crop Uniformity | Consistent moisture distribution across circular zone | Uniform across linear path but edges may vary |

Introduction to Large-Scale Grain Irrigation Methods

Pivot irrigation systems provide efficient water distribution through rotating sprinkler arms, optimizing coverage for circular field patterns commonly found in large-scale grain production. Linear move irrigation offers uniform water application across rectangular fields by moving sprinkler units linearly, making it ideal for irregular field shapes or where consistent water coverage is needed. Both methods enhance water use efficiency and crop yield, but selection depends on field geometry, crop type, and operational cost considerations.

Overview of Pivot and Linear Move Irrigation Systems

Pivot irrigation systems consist of a central pivot with radial arms that rotate around a fixed point, delivering water evenly across large circular fields, enhancing water-use efficiency in grain production. Linear move irrigation systems operate by moving a long, straight sprinkler structure in a linear path across rectangular fields, providing uniform water distribution ideal for varied field shapes. Both systems optimize water management by reducing runoff and evaporation, but pivot systems are preferred for circular fields while linear move systems suit irregular or rectangular large-scale grain fields.

Mechanisms of Water Distribution: Pivot vs Linear

Pivot irrigation systems utilize a rotating sprinkler arm anchored at a central pivot point, delivering circular water distribution that ensures uniform coverage over large, circular fields. Linear move irrigation operates on a motorized track, moving the sprinkler system in a straight line to provide rectangular water application, ideal for fields with irregular shapes or varying slope gradients. The pivot mechanism typically offers higher water application efficiency with reduced runoff, while linear systems provide flexibility in field layout but may experience overlaps or gaps affecting water uniformity.

Coverage Area and Field Suitability Comparison

Pivot irrigation systems typically cover circular areas up to 130 acres per pivot, making them ideal for large, flat fields with minimal obstructions, while linear move irrigation covers rectangular strips up to 400 acres, offering better adaptability for irregularly shaped or elongated fields. The circular coverage of pivot systems maximizes efficiency on uniform terrain, but they may create unwatered corners in non-circular fields, whereas linear move systems provide more uniform watering across rectangular or irregular plots. Field suitability depends on topography and layout, with pivot irrigation favoring flat, open expanses and linear systems accommodating slopes or diverse field shapes common in large-scale grain production.

Water Use Efficiency in Grain Production

Pivot irrigation systems provide higher water use efficiency for large-scale grain production due to their circular coverage and precision application, reducing water waste and runoff. Linear move irrigation, while suitable for irregularly shaped fields, generally consumes more water per hectare because of overlapping passes and less uniform distribution. Optimizing irrigation scheduling and maintenance in either system enhances grain yield by improving soil moisture retention and minimizing evaporation losses.

Installation and Operational Costs

Pivot irrigation systems generally feature lower installation costs due to simpler design and fewer moving parts compared to linear move irrigation, which requires extensive infrastructure along the entire length of the field. Operational costs for pivot irrigation tend to be reduced as energy consumption is concentrated on a single pivot point, whereas linear move systems require continuous energy input for movement across the field. Large-scale grain production benefits from pivot irrigation's cost efficiency, enabling optimized water distribution with minimized expenditure on maintenance and power.

Maintenance Requirements and Longevity

Pivot irrigation systems typically offer lower maintenance requirements due to their centralized pivot point and fewer moving parts, enhancing operational efficiency in large-scale grain production. Linear move irrigation systems require more frequent maintenance on wheels and drive mechanisms because of their extensive lateral movement across fields, potentially increasing downtime. Longevity for pivot systems often surpasses linear moves, benefiting from robust construction and simpler mechanical design, making pivots a more durable choice for prolonged agricultural use.

Impact on Crop Yield and Uniformity

Pivot irrigation systems provide consistent water distribution by rotating around a central point, enhancing uniformity and promoting higher crop yields in large-scale grain production. Linear move irrigation offers flexibility in field coverage but may result in variable water application rates, potentially affecting uniformity and yield stability. Optimizing irrigation scheduling and technology integration can mitigate disparities, ensuring efficient water use and maximizing grain productivity.

Technological Advancements and Automation

Pivot irrigation systems utilize advanced GPS and variable rate technology to optimize water distribution, reducing waste and enhancing crop yield consistency in large-scale grain production. Linear move irrigation offers precise automation through programmable controls that adapt to field topography, ensuring uniform water application in irregularly shaped fields. Integration of real-time monitoring and IoT sensors in both systems facilitates data-driven water management, improving efficiency and sustainability in expansive agricultural operations.

Choosing the Right System for Large-Scale Grain Farms

Pivot irrigation systems offer uniform water distribution with efficient coverage of circular fields, making them ideal for large-scale grain production on expansive, flat terrains. Linear move irrigation provides adaptability for rectangular or irregularly shaped fields, allowing precise water application along linear pathways, which helps optimize water use efficiency in varied farm layouts. Selecting the right system depends on field shape, water availability, and crop water requirements to maximize yield and resource management in grain farming.

Related Important Terms

Variable Rate Irrigation (VRI)

Pivot irrigation systems offer superior efficiency in large-scale grain production by enabling precise Variable Rate Irrigation (VRI) that adjusts water application based on soil variability and crop needs, reducing water waste and enhancing yield. Linear move irrigation provides consistent coverage but lacks the advanced spatial VRI capabilities found in pivot systems, making it less adaptable to heterogeneous field conditions typical in expansive grain farms.

End Gun Coverage Optimization

Pivot irrigation systems optimize end gun coverage by delivering targeted water application at field edges, reducing overlap and runoff, whereas linear move irrigation offers uniform coverage but often requires complicated end gun adjustments to minimize water wastage over extensive grain production fields. Effective end gun coverage optimization in pivot systems enhances water use efficiency and crop yield by precisely tailoring spray patterns to the circular irrigation footprint typical of large-scale grain farming.

GIS-Integrated Pivot Mapping

GIS-integrated pivot mapping enhances precision in large-scale grain production by enabling real-time monitoring and efficient water distribution in pivot irrigation systems, reducing water waste and improving crop yields. Linear move irrigation lacks this advanced spatial analytics integration, making pivot systems more suitable for optimized water management and resource allocation across varied field terrains.

Linear Move Lateral Efficiency

Linear move irrigation systems demonstrate higher lateral efficiency compared to pivot irrigation in large-scale grain production by delivering water more uniformly across rectangular fields, minimizing overlaps and runoff. This improved water distribution enhances crop yield potential while optimizing water and energy use efficiency in extensive agricultural operations.

Drop Span Technology

Pivot irrigation systems equipped with Drop Span Technology offer superior water distribution efficiency and reduced evaporation loss compared to linear move irrigation, making them ideal for large-scale grain production. Drop Span reduces wind drift by lowering sprinkler height during operation, enhancing uniform water application and improving crop yield and water use efficiency.

LEPA (Low Energy Precision Application) Nozzles

LEPA nozzles in pivot irrigation systems deliver water with high uniformity and low energy consumption, enhancing water-use efficiency for large-scale grain production compared to the higher energy demands and less uniform distribution of linear move irrigation. Pivot systems equipped with LEPA technology reduce evaporation and wind drift losses, promoting precise soil moisture maintenance critical for maximizing grain yield and resource conservation.

Field Shape Compatibility Index

Pivot irrigation demonstrates a higher Field Shape Compatibility Index due to its circular watering pattern, maximizing efficiency in square or rectangular grain fields by reducing water overlap and runoff. Linear move irrigation offers better adaptability for irregularly shaped large-scale grain production fields, ensuring uniform water distribution along elongated or non-circular field geometries.

Remote Telemetry Control Systems

Pivot irrigation systems equipped with advanced remote telemetry control enable precise water distribution and real-time monitoring, enhancing efficiency in large-scale grain production. Linear move irrigation with telemetry offers flexible coverage and automated adjustments but may require more complex coordination for uniform water application across expansive fields.

Mobile Drip Irrigation (MDI) on Linear Systems

Mobile Drip Irrigation (MDI) integrated with linear move irrigation systems optimizes water use efficiency by delivering precise volumes directly to the root zone, reducing evaporation and runoff compared to pivot irrigation in large-scale grain production. This method enhances uniformity and flexibility over uneven terrains, offering significant water savings and improved crop yields in extensive agricultural operations.

Wheel Track Management

Pivot irrigation systems offer superior wheel track management in large-scale grain production by minimizing soil compaction through centralized circular movement, whereas linear move irrigation tends to cause more extensive wheel track damage due to its repetitive linear paths. Effective wheel track management in pivot systems enhances soil aeration and water infiltration, promoting better crop growth and yield stability.

Pivot irrigation vs Linear move irrigation for large-scale grain production Infographic

agridif.com

agridif.com