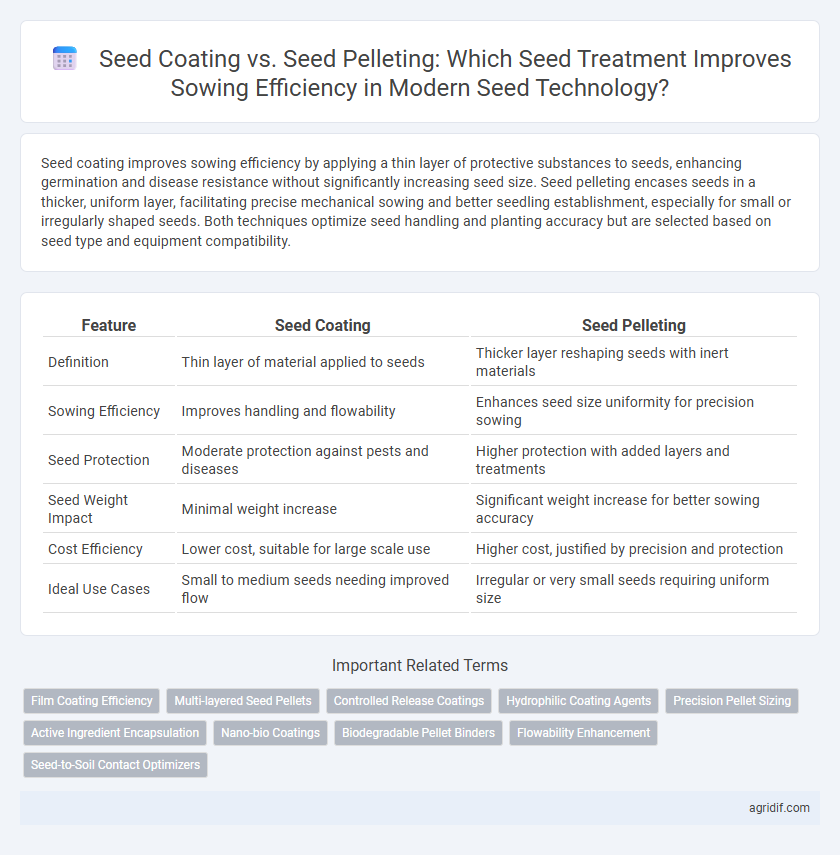

Seed coating improves sowing efficiency by applying a thin layer of protective substances to seeds, enhancing germination and disease resistance without significantly increasing seed size. Seed pelleting encases seeds in a thicker, uniform layer, facilitating precise mechanical sowing and better seedling establishment, especially for small or irregularly shaped seeds. Both techniques optimize seed handling and planting accuracy but are selected based on seed type and equipment compatibility.

Table of Comparison

| Feature | Seed Coating | Seed Pelleting |

|---|---|---|

| Definition | Thin layer of material applied to seeds | Thicker layer reshaping seeds with inert materials |

| Sowing Efficiency | Improves handling and flowability | Enhances seed size uniformity for precision sowing |

| Seed Protection | Moderate protection against pests and diseases | Higher protection with added layers and treatments |

| Seed Weight Impact | Minimal weight increase | Significant weight increase for better sowing accuracy |

| Cost Efficiency | Lower cost, suitable for large scale use | Higher cost, justified by precision and protection |

| Ideal Use Cases | Small to medium seeds needing improved flow | Irregular or very small seeds requiring uniform size |

Introduction to Seed Enhancement Techniques

Seed coating enhances sowing efficiency by applying a thin layer of protective materials, improving seed handling, germination, and disease resistance without significantly altering seed size. In contrast, seed pelleting involves encasing seeds in a bulkier outer layer that standardizes seed shape and size, facilitating precise mechanical sowing and uniform plant spacing. Both techniques optimize seed performance but are selected based on crop type, sowing equipment, and desired agronomic outcomes.

Defining Seed Coating and Seed Pelleting

Seed coating involves applying a thin layer of materials such as polymers, nutrients, or pesticides directly onto the seed surface to enhance protection and improve germination rates. Seed pelleting encases seeds in a uniform, often heavier coating of clay or other inert materials to increase seed size and weight, facilitating precise mechanical sowing and uniform seed placement. Understanding these processes is crucial for optimizing sowing efficiency, as seed coating primarily enhances seed viability while pelleting improves handling and planting accuracy.

Materials Used in Seed Coating vs Pelleting

Seed coating materials typically include polymers, adhesives, fungicides, and insecticides designed to protect and enhance seed germination, while pelleting involves layering seeds with inert fillers like clay, talc, or lime to increase seed size and uniformity for precise mechanical sowing. Coatings offer thin, protective films that maintain seed shape and size, optimizing nutrient and chemical delivery without significantly altering seed handling, whereas pelleting transforms seed morphology to improve placement accuracy and seeding rate control in planting equipment. The choice of materials directly impacts seed sowing efficiency by balancing improved seed protection and mechanical compatibility during planting operations.

Impact on Sowing Efficiency and Precision

Seed coating enhances sowing efficiency by uniformly applying protective chemicals and nutrients, promoting better seed-soil contact and faster germination rates. Seed pelleting improves precision in sowing by increasing seed size and weight, enabling accurate placement in mechanical planters and reducing seed wastage. Both techniques optimize seed handling, but pelleting offers superior control in high-speed planting operations.

Seed Handling and Flowability Improvements

Seed coating improves sowing efficiency by enhancing seed handling and flowability through uniform application of protective materials, which reduces seed damage and improves metering accuracy. Seed pelleting increases seed size and weight, facilitating mechanical sowing with better seed-to-soil contact but may reduce flowability due to increased bulkiness. Optimal seed flowability and handling are achieved by selecting suitable coating thickness and pellet composition tailored to specific sowing equipment and crop requirements.

Germination Rates and Field Emergence

Seed coating enhances germination rates by applying thin layers of protective materials that improve moisture retention and facilitate uniform seed-soil contact, leading to more consistent field emergence. Seed pelleting involves enveloping seeds in larger, often nutrient-enriched pellets that improve sowing precision, especially for small or irregularly shaped seeds, but may slightly delay germination due to thicker barrier layers. Optimizing seed coating or pelleting techniques directly impacts sowing efficiency by balancing rapid germination with improved handling and placement accuracy in agricultural practices.

Compatibility with Modern Sowing Machinery

Seed coating offers enhanced compatibility with modern sowing machinery by maintaining seed size and flow characteristics, ensuring uniform seed planting and reduced machine blockages. Seed pelleting, while improving seed handling by enlarging and rounding seeds, may require machinery adjustments due to increased seed dimensions and altered flow dynamics. Optimizing seed treatment choice based on machinery specifications can significantly boost sowing efficiency and crop establishment.

Cost-Benefit Analysis for Farmers

Seed coating enhances seed sowing efficiency by providing a protective layer that improves seed flowability and germination rates, typically at a lower cost compared to seed pelleting. Seed pelleting involves enveloping seeds in a larger volume of inert material, significantly improving sowing precision and uniformity, but it incurs higher expenses due to increased material and processing requirements. Farmers must weigh the initial investment against yield gains, with seed coating offering cost-effective benefits for small to medium-scale operations, while pelleting suits high-value crops where precision sowing justifies the premium cost.

Environmental Effects of Coated and Pelleted Seeds

Seed coating enhances sowing efficiency by improving seed protection against pathogens and pests while promoting uniform germination, with minimal environmental impact due to targeted application of eco-friendly materials. Seed pelleting transforms irregular seeds into uniform shapes, facilitating precise mechanical sowing but may increase soil disturbance and residue from non-biodegradable components if not properly managed. Both techniques can reduce the need for chemical treatments, contributing to sustainable agriculture by minimizing agrochemical runoff and preserving soil health.

Choosing the Right Technique for Specific Crops

Seed coating enhances sowing efficiency by applying a thin layer of protective and nutrient-enriched materials, ideal for small to medium-sized seeds like vegetables and cereals. Seed pelleting, involving the application of a larger, uniform outer layer, is preferred for irregularly shaped or very small seeds such as lettuce or onions, improving mechanical sowing accuracy and seed placement. Selecting the appropriate seed treatment depends on crop type, seed size, and planting equipment, ensuring optimal germination and growth performance.

Related Important Terms

Film Coating Efficiency

Film coating enhances seed germination by providing a uniform layer that improves moisture retention and protects against pathogens, resulting in higher sowing efficiency compared to seed pelleting. Unlike seed pelleting, which increases seed size and weight, film coating maintains seed size while optimizing seed flow and distribution during planting.

Multi-layered Seed Pellets

Multi-layered seed pellets enhance sowing efficiency by providing precise seed placement and improved protection against pests and environmental stress compared to traditional seed coatings. These pellets incorporate multiple nutrient and polymer layers, optimizing germination rates and enabling uniform seed distribution in various soil conditions.

Controlled Release Coatings

Controlled release seed coatings enhance sowing efficiency by precisely regulating the delivery of nutrients, pesticides, and growth stimulants, optimizing seed germination and early seedling vigor. Compared to seed pelleting, these coatings minimize seed size alteration and improve compatibility with mechanical sowing equipment, leading to uniform seed placement and higher crop establishment rates.

Hydrophilic Coating Agents

Hydrophilic coating agents in seed coating enhance water absorption and uniform germination rates, improving sowing efficiency by promoting rapid seed imbibition and early seedling vigor. In contrast, seed pelleting primarily modifies seed size and shape for mechanical sowing precision, with less direct impact on water uptake dynamics.

Precision Pellet Sizing

Precision pellet sizing in seed pelleting significantly enhances sowing efficiency by ensuring uniform seed placement and optimal soil contact, which promotes consistent germination rates. Unlike seed coating, which primarily protects the seed, precision pelleting standardizes pellet dimensions to improve mechanical sowing accuracy and reduce seed wastage.

Active Ingredient Encapsulation

Seed coating provides a thin layer embedding active ingredients that enhance germination and protect against pests with minimal seed size increase, optimizing sowing density and precision. Seed pelleting encapsulates seeds in a larger, uniform shell containing active compounds, improving seed handling and uniformity but potentially requiring adjustment in sowing equipment due to increased seed diameter.

Nano-bio Coatings

Nano-bio coatings enhance seed coating by improving germination rates, disease resistance, and nutrient delivery through precise nanoscale encapsulation, whereas seed pelleting primarily modifies seed size and shape for mechanical sowing compatibility. Integrating nanotechnology in seed coatings offers superior sowing efficiency and crop uniformity compared to traditional pelleting methods by enabling targeted bioactive compound release and environmental stress protection.

Biodegradable Pellet Binders

Seed coating enhances sowing efficiency by applying a thin layer of protective film, while seed pelleting involves encasing seeds in a larger, uniform biodegradable pellet that improves handling and precise placement. Biodegradable pellet binders not only support seed integrity during sowing but also decompose naturally, reducing environmental impact and promoting sustainable agriculture.

Flowability Enhancement

Seed coating enhances sowing efficiency by creating a uniform layer around seeds, improving flowability and protecting seeds from environmental stress. Seed pelleting, while also increasing size and weight for better metering, offers superior flowability enhancements by transforming irregular seeds into smooth, evenly shaped pellets ideal for mechanical sowing.

Seed-to-Soil Contact Optimizers

Seed coating enhances seed-to-soil contact by providing a thin, uniform layer that improves moisture retention and protects seeds from pathogens, thus optimizing germination rates. In contrast, seed pelleting encases seeds in a thicker, shaped layer that ensures better seed placement and uniform depth during sowing, increasing precision and reducing seed loss for efficient crop establishment.

Seed Coating vs Seed Pelleting for Sowing Efficiency Infographic

agridif.com

agridif.com