Axial-flow threshers provide higher efficiency and faster grain separation compared to pedal-powered threshers, making them suitable for large-scale agricultural operations. Pedal-powered threshers offer affordability and ease of use in smallholder farms but generally require more manual labor and longer processing times. Both types impact grain quality and throughput, with axial-flow models typically delivering cleaner separation and reduced grain damage.

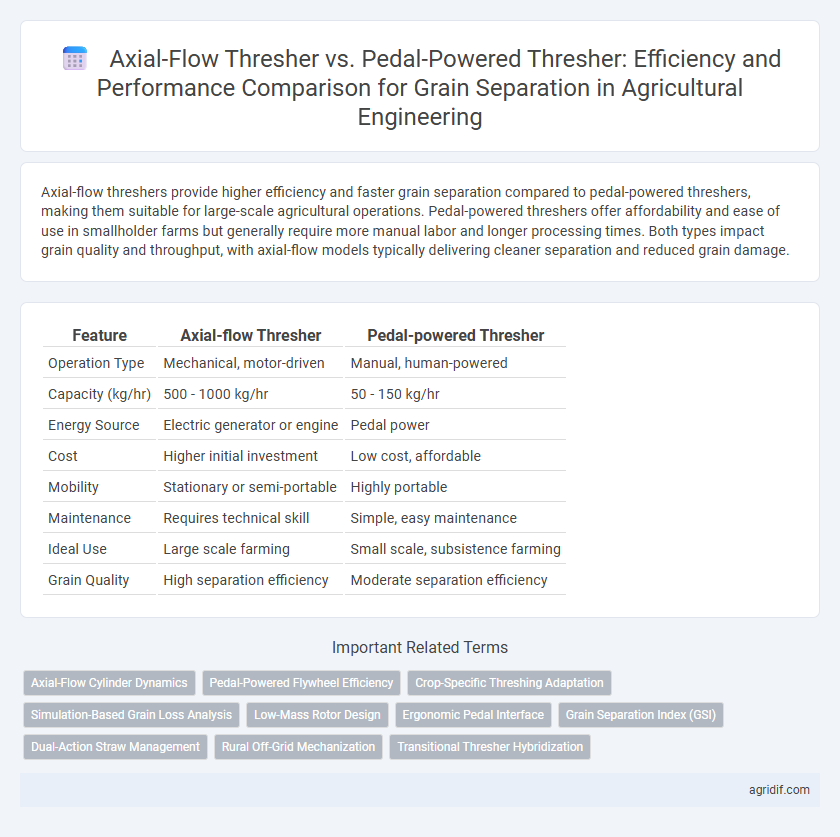

Table of Comparison

| Feature | Axial-flow Thresher | Pedal-powered Thresher |

|---|---|---|

| Operation Type | Mechanical, motor-driven | Manual, human-powered |

| Capacity (kg/hr) | 500 - 1000 kg/hr | 50 - 150 kg/hr |

| Energy Source | Electric generator or engine | Pedal power |

| Cost | Higher initial investment | Low cost, affordable |

| Mobility | Stationary or semi-portable | Highly portable |

| Maintenance | Requires technical skill | Simple, easy maintenance |

| Ideal Use | Large scale farming | Small scale, subsistence farming |

| Grain Quality | High separation efficiency | Moderate separation efficiency |

Introduction to Threshing Technologies in Agriculture

Axial-flow threshers utilize a rotary drum to efficiently separate grain from the stalk, offering higher throughput and reduced grain damage compared to traditional methods. Pedal-powered threshers operate manually through human energy, making them suitable for small-scale farmers with limited access to electricity or fuel but often result in lower processing capacity and longer operation times. Advances in threshing technologies emphasize balancing energy efficiency, cost, and throughput to enhance productivity in diverse agricultural settings.

Overview of Axial-flow Threshers

Axial-flow threshers use a continuous, cylindrical rotor to separate grains efficiently by employing centrifugal force and abrasion, significantly increasing throughput compared to pedal-powered threshers. These machines are designed for high-capacity grain processing, reducing labor intensity and time requirements in large-scale agricultural operations. Their mechanized operation allows for consistent grain quality and minimizes losses, making axial-flow threshers ideal for modern grain separation needs.

Overview of Pedal-powered Threshers

Pedal-powered threshers utilize human energy to separate grains, providing an affordable and eco-friendly alternative to motorized axial-flow threshers. These machines are lightweight, portable, and well-suited for smallholder farmers in regions with limited access to electricity or fuel. Their design typically features a foot-operated pedal system connected to a rotating cylinder that efficiently threshes grain while minimizing grain damage and loss.

Mechanisms of Grain Separation

Axial-flow threshers use rotary cylinders with rasp bars that accelerate grains along a horizontal axis, efficiently separating grain from straw through centrifugal and impact forces. Pedal-powered threshers rely on manual pedaling to rotate a drum or concave, with grain separation achieved by friction and beating actions at lower speeds. The axial-flow mechanism typically offers higher throughput and cleaner separation due to continuous, high-speed processing, while pedal-powered threshers provide simplicity and energy efficiency suitable for small-scale farming.

Efficiency Comparison: Axial-flow vs Pedal-powered Threshers

Axial-flow threshers exhibit higher efficiency in grain separation by delivering continuous, high-capacity processing that minimizes grain breakage and loss. Pedal-powered threshers rely on manual input, resulting in lower throughput and increased labor intensity, making them less suitable for large-scale operations. The axial-flow design optimizes crop flow dynamics, enhancing separation quality and operational speed compared to the intermittent action of pedal-powered threshers.

Energy Consumption and Power Requirements

Axial-flow threshers typically consume higher energy due to their motorized operation, requiring power sources ranging from 5 to 15 kW to efficiently separate grain from stalks, suitable for large-scale farming. Pedal-powered threshers demand significantly less external energy, relying on human power with an average input of around 100 to 200 watts, making them ideal for smallholder farmers in off-grid areas. The choice between the two hinges on balancing energy availability and power requirements against throughput capacity and operational efficiency.

Grain Quality and Post-threshing Losses

Axial-flow threshers typically provide higher grain quality with fewer broken grains due to their controlled, continuous threshing action, reducing both physical damage and contamination. Pedal-powered threshers often result in increased post-threshing losses and grain breakage caused by uneven manual operation and less efficient separation mechanisms. Therefore, axial-flow threshers are preferred for minimizing grain damage and optimizing yield in large-scale grain separation processes.

Suitability for Smallholder vs Large-scale Farms

Axial-flow threshers provide high throughput and efficiency, making them suitable for large-scale farms with substantial grain processing demands. Pedal-powered threshers offer a cost-effective and energy-efficient solution ideal for smallholder farmers with limited land and financial resources. The choice depends on farm size and resource availability, with axial-flow threshers favored for mechanized, high-volume operations and pedal-powered models for low-cost, low-capacity requirements.

Economic and Environmental Considerations

Axial-flow threshers offer higher efficiency and faster grain separation but require significant fuel or electricity, increasing operational costs and carbon emissions. Pedal-powered threshers have minimal energy costs and zero emissions, making them economically accessible and environmentally sustainable for small-scale farmers. Choosing between them depends on balancing throughput needs with available resources and environmental impact goals.

Future Trends in Thresher Development

Future trends in thresher development emphasize improving efficiency and sustainability, with axial-flow threshers advancing through automation and sensor integration for optimized grain separation. Pedal-powered threshers are evolving to incorporate lightweight materials and ergonomic designs, increasing accessibility in remote areas while reducing physical strain on users. Both technologies show promise in integrating IoT for real-time monitoring, enhancing performance, and enabling data-driven farming practices.

Related Important Terms

Axial-Flow Cylinder Dynamics

Axial-flow threshers employ a high-speed rotating cylinder with helical rasp bars that create a continuous axial movement of grain and straw, enhancing separation efficiency through centrifugal and rubbing forces, unlike pedal-powered threshers which rely on manual rotation with limited throughput. The dynamic design of the axial-flow cylinder reduces grain damage and increases capacity, making it ideal for large-scale grain separation in agricultural engineering.

Pedal-Powered Flywheel Efficiency

Pedal-powered threshers utilize a flywheel system to convert human mechanical energy into consistent rotational motion, enhancing grain separation efficiency by maintaining steady drum speed and reducing kernel damage. This design offers increased energy efficiency compared to axial-flow threshers by maximizing power transfer through the pedal-flywheel mechanism, making it ideal for small-scale farming with limited fuel resources.

Crop-Specific Threshing Adaptation

Axial-flow threshers offer high efficiency and adaptability for large-scale crops such as wheat and maize through adjustable cylinder speed and concave clearance, optimizing grain separation and minimizing damage. Pedal-powered threshers provide tailored threshing solutions for small-scale farmers dealing with diverse crops like rice and millets, allowing precise control over threshing intensity to reduce grain loss and preserve quality.

Simulation-Based Grain Loss Analysis

Simulation-based grain loss analysis reveals axial-flow threshers typically achieve lower grain loss rates, averaging 2-4%, due to their high-capacity, continuous operation that efficiently separates grains from stalks. Pedal-powered threshers, while cost-effective and energy-efficient for small-scale farming, exhibit higher grain loss rates, often exceeding 6%, as simulation models indicate reduced throughput and increased seed damage under manual operation.

Low-Mass Rotor Design

Low-mass rotor design in axial-flow threshers enhances grain separation efficiency by reducing inertia, leading to lower energy consumption and minimized grain damage compared to pedal-powered threshers. This design allows for higher throughput and consistent threshing performance, critical for large-scale agricultural operations.

Ergonomic Pedal Interface

The ergonomic pedal interface of the pedal-powered thresher reduces operator fatigue and enhances control, making it suitable for small-scale farmers in regions with limited access to electricity. In contrast, the axial-flow thresher, powered by engines, offers higher throughput but often lacks ergonomic design features, resulting in greater physical strain during manual operation or maintenance.

Grain Separation Index (GSI)

Axial-flow threshers exhibit a higher Grain Separation Index (GSI), typically exceeding 90%, due to their continuous axial movement and efficient grain cleaning mechanisms that minimize grain damage and loss. Pedal-powered threshers generally achieve a lower GSI around 70-80%, limited by manual operation speed and less optimized separation, making axial-flow models more effective for large-scale grain processing.

Dual-Action Straw Management

Axial-flow threshers offer efficient grain separation with dual-action straw management by simultaneously threshing and separating grains while minimizing straw damage, enhancing fodder quality and reducing post-harvest losses. Pedal-powered threshers provide a cost-effective, manual alternative suitable for small-scale farmers, featuring basic dual-action straw management that allows moderate grain separation but may result in higher straw breakage and lower throughput.

Rural Off-Grid Mechanization

Axial-flow threshers offer higher throughput and efficiency for grain separation compared to pedal-powered threshers, making them suitable for small to medium-scale rural off-grid farms with access to mechanical power sources. Pedal-powered threshers provide cost-effective, low-energy solutions ideal for remote off-grid communities lacking fuel or electricity, enabling sustainable grain processing without reliance on fossil fuels.

Transitional Thresher Hybridization

Transitional thresher hybridization combines the mechanical efficiency of axial-flow threshers with the low energy cost and accessibility of pedal-powered threshers, optimizing grain separation in small to medium-scale farming. This hybrid approach enhances throughput and reduces grain damage by integrating controlled axial flow and human-powered mechanical input, improving overall operational sustainability.

Axial-flow thresher vs Pedal-powered thresher for grain separation Infographic

agridif.com

agridif.com