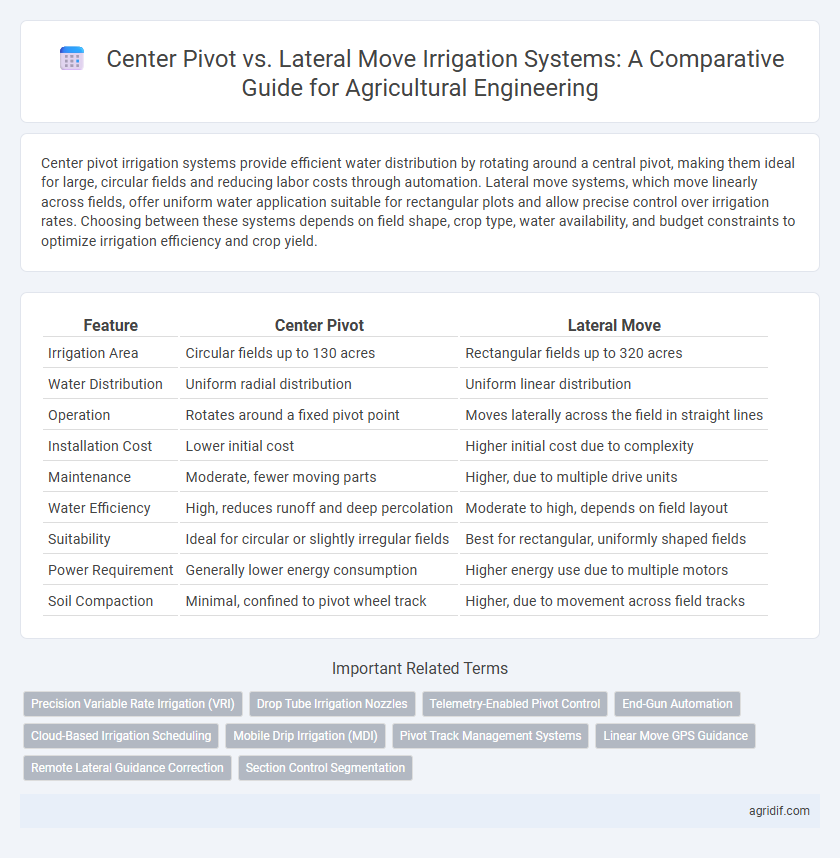

Center pivot irrigation systems provide efficient water distribution by rotating around a central pivot, making them ideal for large, circular fields and reducing labor costs through automation. Lateral move systems, which move linearly across fields, offer uniform water application suitable for rectangular plots and allow precise control over irrigation rates. Choosing between these systems depends on field shape, crop type, water availability, and budget constraints to optimize irrigation efficiency and crop yield.

Table of Comparison

| Feature | Center Pivot | Lateral Move |

|---|---|---|

| Irrigation Area | Circular fields up to 130 acres | Rectangular fields up to 320 acres |

| Water Distribution | Uniform radial distribution | Uniform linear distribution |

| Operation | Rotates around a fixed pivot point | Moves laterally across the field in straight lines |

| Installation Cost | Lower initial cost | Higher initial cost due to complexity |

| Maintenance | Moderate, fewer moving parts | Higher, due to multiple drive units |

| Water Efficiency | High, reduces runoff and deep percolation | Moderate to high, depends on field layout |

| Suitability | Ideal for circular or slightly irregular fields | Best for rectangular, uniformly shaped fields |

| Power Requirement | Generally lower energy consumption | Higher energy use due to multiple motors |

| Soil Compaction | Minimal, confined to pivot wheel track | Higher, due to movement across field tracks |

Introduction to Mechanized Irrigation Systems

Center pivot and lateral move systems represent two primary mechanized irrigation technologies widely adopted for efficient water management in agriculture. Center pivot systems rotate around a central pivot, delivering uniform water application over circular fields, optimizing water use efficiency and reducing labor costs. Lateral move systems traverse linearly across rectangular fields, offering precise irrigation control suited for larger, irregularly shaped plots, enhancing crop yield through targeted water distribution.

Center Pivot Irrigation: Overview and Mechanism

Center pivot irrigation systems consist of a long, rotating arm anchored at a central pivot point, delivering water efficiently over circular fields through evenly spaced sprinklers. This mechanism provides uniform water distribution by moving continuously around the pivot, optimizing water usage and reducing labor costs. Advanced sensors and automation enhance the system's precision, making it suitable for large-scale agricultural operations.

Lateral Move Irrigation: Overview and Mechanism

Lateral move irrigation systems consist of a series of connected spans mounted on wheeled towers that move laterally across rectangular fields, providing uniform water distribution through adjustable sprinkler nozzles. These systems are powered by electric or hydraulic motors controlled by a central panel, ensuring precise speed regulation to optimize irrigation efficiency based on soil moisture and crop needs. Compared to center pivot systems, lateral move irrigation offers better adaptability for irregular field shapes and varying topographies, enhancing water conservation and crop yield in diverse agricultural applications.

Water Distribution Efficiency: Center Pivot vs Lateral Move

Center pivot irrigation systems typically achieve water distribution efficiency rates of 85-90%, offering uniform application across circular fields. In contrast, lateral move systems provide efficiency around 75-85%, with greater variability due to linear movement and field shape constraints. Water distribution uniformity in center pivots reduces runoff and deep percolation, optimizing water use compared to lateral move systems.

Field Shape and Size Suitability Comparison

Center pivot irrigation systems are best suited for circular fields or large, uniform areas due to their fixed radial pattern, optimizing water distribution in fields typically ranging from 40 to 130 acres. Lateral move systems excel in rectangular or irregularly shaped fields, providing flexible coverage and scalability for fields spanning 10 to 100 acres or more by moving laterally across the terrain. Field shape and size directly impact irrigation efficiency, with center pivots maximizing uniformity in round fields and lateral moves offering adaptability for diverse crop layouts and topographies.

Installation and Operational Costs Analysis

Center pivot irrigation systems generally have lower installation costs due to simpler design and fewer components compared to lateral move systems, which require extensive pipe networks and multiple pumping stations. Operational costs for center pivots tend to be more economical as they consume less energy and require less labor for maintenance, while lateral move systems can incur higher expenses due to frequent adjustments and complex mechanical parts. Analyzing cost-efficiency, center pivot systems are often preferred for large, uniform fields, whereas lateral move systems may justify their higher costs in irregularly shaped or varied terrain requiring precise irrigation control.

Maintenance Requirements and Longevity

Center pivot irrigation systems generally require less frequent maintenance due to their simpler mechanical structure and fewer moving parts compared to lateral move systems, which can have more complex track and wheel assemblies prone to wear. The longevity of center pivot systems often exceeds that of lateral move systems, with expected operational lifespans of 15 to 20 years when properly maintained, while lateral move systems typically last 10 to 15 years. Regular inspections, timely replacement of worn components, and proper lubrication are critical maintenance practices that enhance performance and extend the lifespan of both irrigation system types.

Water Use Efficiency and Conservation

Center pivot irrigation systems typically achieve higher water use efficiency by delivering water uniformly across circular fields, minimizing runoff and deep percolation losses. Lateral move systems offer precise control over irrigation timing and amount on rectangular fields, reducing water waste and promoting conservation through targeted application. Both systems incorporate advanced monitoring technologies to optimize water distribution, enhancing sustainable water management in agricultural engineering.

Crop Adaptability and Performance

Center pivot irrigation systems offer superior crop adaptability for circular fields and high-efficiency water distribution, enhancing yield uniformity in crops like corn and soybeans. Lateral move systems provide flexibility for rectangular fields and row crops such as vegetables and cotton, promoting uniform water application across the field length. Performance differences depend on field shape and crop type, with center pivots excelling in water use efficiency and lateral moves optimizing coverage for varied terrain and crop layouts.

Environmental and Resource Considerations

Center pivot irrigation systems often use less water due to their circular coverage, reducing runoff and evaporation losses, which enhances water-use efficiency in agricultural fields. Lateral move systems cover rectangular areas, enabling more precise water application but can result in higher water consumption and increased energy use due to longer pipeline lengths and pump operations. Both systems require careful soil moisture monitoring to minimize water wastage and protect surrounding ecosystems by preventing nutrient leaching and soil erosion.

Related Important Terms

Precision Variable Rate Irrigation (VRI)

Center pivot irrigation systems enable precise variable rate irrigation (VRI) by utilizing GPS and soil data to apply water variably across circular fields, optimizing water use efficiency. Lateral move systems also support VRI with linear movement and adaptable sprinkler zones, suitable for rectangular fields requiring uniform but customizable water application.

Drop Tube Irrigation Nozzles

Drop tube irrigation nozzles in center pivot systems enhance water distribution efficiency by delivering water closer to the crop canopy, reducing evaporation and wind drift compared to lateral move systems. Their vertical placement allows precise application in uneven terrains, improving uniformity and minimizing water waste in large-scale agricultural fields.

Telemetry-Enabled Pivot Control

Telemetry-enabled pivot control enhances center pivot irrigation systems by providing real-time monitoring and adjustment capabilities, optimizing water application efficiency and reducing labor costs. Unlike lateral move systems, center pivots equipped with telemetry offer precise data on soil moisture, weather conditions, and system performance, enabling adaptive irrigation management tailored to crop needs.

End-Gun Automation

Center pivot irrigation systems equipped with automated end-gun controls optimize water distribution by adjusting spray patterns based on field geometry, reducing water waste and improving crop uniformity. In contrast, lateral move systems primarily rely on manual or less advanced automation for end-gun operation, often resulting in less precise irrigation coverage and higher water consumption.

Cloud-Based Irrigation Scheduling

Cloud-based irrigation scheduling leverages real-time data and remote monitoring to optimize water application in both center pivot and lateral move systems, enhancing precision and reducing water waste. Integration of IoT sensors and AI analytics in these systems ensures adaptive irrigation tailored to crop needs, soil moisture levels, and weather forecasts, improving overall agricultural efficiency and sustainability.

Mobile Drip Irrigation (MDI)

Center pivot and lateral move systems provide efficient large-scale irrigation, but Mobile Drip Irrigation (MDI) enhances water use efficiency by delivering precise water application directly to the root zone, reducing evaporation and runoff. MDI integrates mobility with drip technology, offering flexibility and uniform water distribution ideal for crops sensitive to water stress in diverse field conditions.

Pivot Track Management Systems

Center pivot irrigation systems utilize Pivot Track Management Systems to optimize wheel line alignment and reduce soil compaction, enhancing irrigation efficiency on uneven terrains. These systems employ GPS and sensor technology to monitor pivot tracks, minimizing track damage and improving machine longevity compared to lateral move systems.

Linear Move GPS Guidance

Lateral move irrigation systems equipped with Linear Move GPS Guidance enhance precision in water distribution by enabling automated, real-time adjustments based on field geometry and crop needs, reducing water waste compared to traditional center pivot systems. This GPS-guided technology optimizes irrigation efficiency, minimizes overlap, and supports uniform crop growth across irregularly shaped agricultural fields.

Remote Lateral Guidance Correction

Center pivot irrigation systems provide efficient water distribution for circular fields, while lateral move systems cover rectangular areas with precise control; Remote Lateral Guidance Correction enhances lateral move irrigation by using GPS technology to automatically adjust wheel alignment, improving water application uniformity and reducing labor costs. This innovative guidance system minimizes soil compaction and operational errors, promoting sustainable irrigation practices in agricultural engineering.

Section Control Segmentation

Center pivot irrigation systems utilize section control segmentation to precisely manage water distribution by activating specific pivot spans, reducing overlap and minimizing water waste. Lateral move systems employ segmented control panels that enable targeted irrigation across rectangular fields, optimizing water use efficiency and crop growth uniformity.

Center pivot vs Lateral move systems for irrigation Infographic

agridif.com

agridif.com