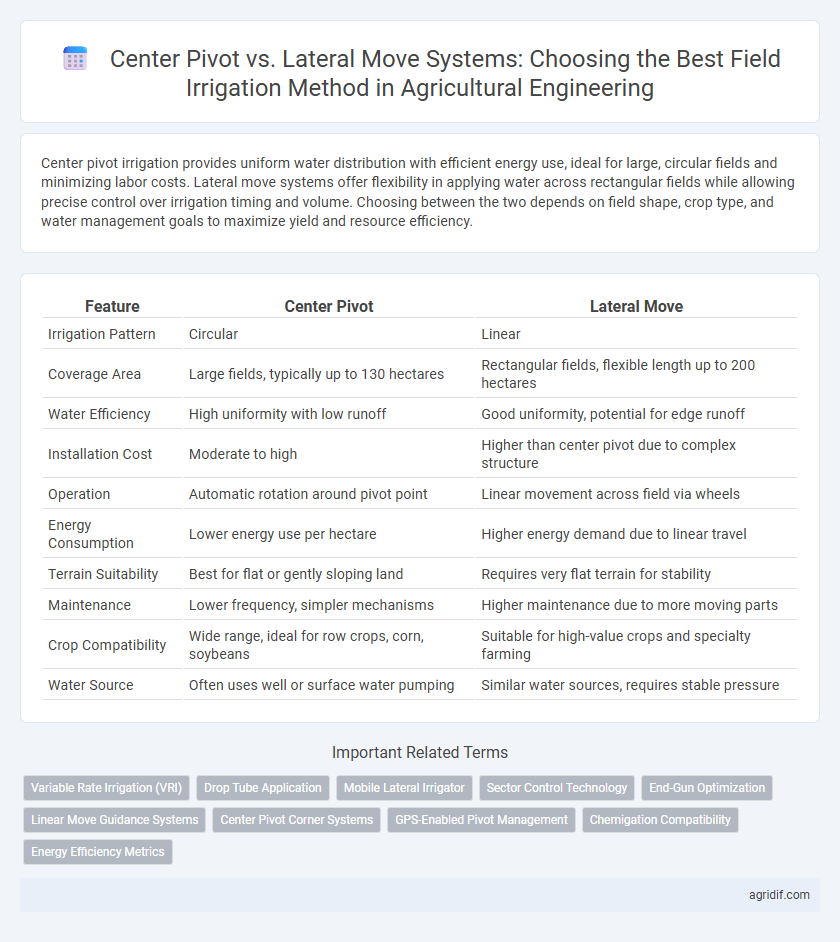

Center pivot irrigation provides uniform water distribution with efficient energy use, ideal for large, circular fields and minimizing labor costs. Lateral move systems offer flexibility in applying water across rectangular fields while allowing precise control over irrigation timing and volume. Choosing between the two depends on field shape, crop type, and water management goals to maximize yield and resource efficiency.

Table of Comparison

| Feature | Center Pivot | Lateral Move |

|---|---|---|

| Irrigation Pattern | Circular | Linear |

| Coverage Area | Large fields, typically up to 130 hectares | Rectangular fields, flexible length up to 200 hectares |

| Water Efficiency | High uniformity with low runoff | Good uniformity, potential for edge runoff |

| Installation Cost | Moderate to high | Higher than center pivot due to complex structure |

| Operation | Automatic rotation around pivot point | Linear movement across field via wheels |

| Energy Consumption | Lower energy use per hectare | Higher energy demand due to linear travel |

| Terrain Suitability | Best for flat or gently sloping land | Requires very flat terrain for stability |

| Maintenance | Lower frequency, simpler mechanisms | Higher maintenance due to more moving parts |

| Crop Compatibility | Wide range, ideal for row crops, corn, soybeans | Suitable for high-value crops and specialty farming |

| Water Source | Often uses well or surface water pumping | Similar water sources, requires stable pressure |

Introduction to Mechanized Field Irrigation Systems

Center pivot and lateral move irrigation systems represent two primary mechanized field irrigation methods widely used to optimize water distribution efficiency. Center pivot systems rotate around a central pivot point, providing uniform irrigation over circular fields, while lateral move systems travel laterally across rectangular fields for precise water application. These mechanized systems enhance water conservation, labor efficiency, and crop yield compared to traditional irrigation techniques.

Overview: Center Pivot vs Lateral Move Irrigation

Center pivot irrigation systems utilize a rotating sprinkler arm anchored at a central pivot point, providing efficient water distribution over circular fields with uniform coverage and reduced labor requirements. Lateral move irrigation systems employ a linear sprinkler mechanism that moves across rectangular fields, offering greater flexibility in field shapes but often requiring more energy and maintenance due to continuous lateral movement. Both systems optimize water use in agricultural engineering, with center pivots favored for their automation and lower operational complexity, while lateral moves suit diverse terrain and crop patterns requiring precise irrigation control.

System Design and Operational Principles

Center pivot irrigation systems feature a radial design where a central pivot distributes water uniformly in a circular pattern, facilitating efficient energy use and minimal labor. Lateral move systems operate by traversing the field in straight lines, delivering water through linear pipes supported by towers that incrementally advance. The choice between center pivot and lateral move irrigation depends on field shape, water source availability, and maintenance preferences, impacting overall water distribution efficiency and crop yield optimization.

Field Shape and Size Compatibility

Center pivot irrigation systems are ideal for large, circular fields and efficiently cover up to 130 acres per pivot, maximizing water distribution with minimal labor. Lateral move systems are better suited for rectangular or irregularly shaped fields, providing uniform irrigation across extensive lengths, often over 1000 feet, ensuring adaptability in varying terrain. Choosing between center pivot and lateral move depends on field geometry and size, impacting irrigation uniformity, energy use, and installation cost.

Water Distribution Uniformity and Efficiency

Center pivot irrigation systems provide superior water distribution uniformity by delivering consistent coverage in circular patterns, minimizing water waste and optimizing crop hydration. Lateral move systems, while effective for rectangular fields, may experience uneven water application at system edges, potentially reducing irrigation efficiency. Evaluating soil type, field geometry, and water source sustainability is critical when selecting between these systems to maximize overall irrigation performance.

Installation, Maintenance, and Mobility

Center pivot irrigation systems require a simpler installation process with a fixed central point allowing easier setup, while lateral move systems involve more complex layout and anchoring across large fields. Maintenance for center pivots is generally lower due to fewer moving parts and centralized components, whereas lateral move systems demand regular monitoring along extensive travel paths. Mobility favors lateral move systems with their ability to traverse fields for uniform coverage, contrasted with center pivots which irrigate in circular patterns around a fixed pivot.

Energy and Water Consumption Comparison

Center pivot irrigation systems typically consume less energy per acre compared to lateral move systems due to their circular coverage and efficient water distribution patterns. Water application efficiency in center pivots often exceeds 85%, minimizing runoff and deep percolation losses, whereas lateral move systems may experience uneven water distribution and higher evaporation rates. Selecting center pivot systems can lead to significant reductions in both water and energy consumption, enhancing sustainability in agricultural water management.

Cost Analysis: Initial Investment and Long-term Operation

Center pivot irrigation systems require a higher initial investment, often ranging from $50,000 to $150,000 depending on field size, but offer lower maintenance costs and greater water-use efficiency over time. Lateral move systems, while having a lower upfront cost typically between $30,000 and $100,000, involve increased labor and energy expenses due to their complexity and continuous movement across the field. Long-term operational costs reveal that center pivots minimize energy consumption and maintenance needs, leading to better cost-effectiveness for large-scale farming operations.

Crop Adaptability and Productivity Impact

Center pivot irrigation systems excel in large, circular fields and are highly adaptable to a variety of crops such as corn, wheat, and soybeans, optimizing water distribution for improved yield. Lateral move systems cover rectangular fields, offering uniform water application that enhances productivity for row crops like vegetables and cotton by minimizing water stress. Crop adaptability and productivity are influenced by field shape and system design, with center pivots boosting efficiency on irregular terrains and lateral moves providing precise irrigation control for diverse crop requirements.

Choosing the Right System: Factors for Decision-Making

Choosing the appropriate irrigation system depends on field size, shape, soil type, and water availability. Center pivot systems excel in circular fields and offer efficient water distribution with lower labor costs, while lateral move systems suit rectangular fields and provide uniform coverage with flexible application rates. Evaluating crop type, terrain slope, and budget constraints ensures optimal water management and maximizes crop yield.

Related Important Terms

Variable Rate Irrigation (VRI)

Center Pivot systems equipped with Variable Rate Irrigation (VRI) technology enable precise water application by adjusting irrigation rates based on soil variability and crop needs, enhancing water use efficiency and crop yield uniformity. Lateral Move systems with VRI offer similar benefits but are better suited for rectangular fields, providing uniform lateral coverage and optimized water distribution across varying soil zones.

Drop Tube Application

Center pivot irrigation systems utilize drop tubes to deliver water directly to crops with minimal evaporation loss, optimizing water efficiency in circular fields. In contrast, lateral move systems employ elevated drop tubes that ensure uniform water distribution across rectangular fields, enhancing irrigation uniformity and crop yield.

Mobile Lateral Irrigator

Mobile lateral irrigators offer enhanced flexibility for uneven or irregularly shaped fields compared to center pivot systems, allowing precise water application along contour lines. These systems improve water efficiency and reduce labor by moving laterally on wheels, making them ideal for diverse topographies and variable crop needs.

Sector Control Technology

Sector control technology in center pivot irrigation enables precise water application by dividing the field into multiple sectors, improving water use efficiency and crop yield. Lateral move systems lack such advanced sector control, often resulting in less uniform irrigation and higher water consumption.

End-Gun Optimization

End-gun optimization in center pivot irrigation enhances water distribution efficiency by precisely controlling application rates at the system's outer reaches, reducing runoff and ensuring uniform crop hydration. In contrast, lateral move systems require tailored end-gun adjustments to minimize overlap and water waste, critical for maximizing irrigation effectiveness across rectangular fields.

Linear Move Guidance Systems

Linear move guidance systems in lateral move irrigation utilize GPS and laser technology to ensure precise alignment and uniform water distribution across fields, minimizing overlap and runoff. These systems enhance operational efficiency compared to center pivot irrigation by allowing adjustable lateral movement tailored to field shape and topography, optimizing crop water usage.

Center Pivot Corner Systems

Center pivot corner systems enhance irrigation efficiency by extending water coverage beyond the traditional circular pattern, utilizing corner booms or wheel lines to irrigate rectangular fields. These systems reduce water waste and improve uniformity, making them preferable in large-scale agricultural operations with irregularly shaped plots.

GPS-Enabled Pivot Management

GPS-enabled pivot management in center pivot irrigation systems enhances precision in water application by optimizing pivot positioning and movement based on real-time spatial data, reducing water waste and improving crop yield uniformity. Lateral move systems, while effective, lack the advanced spatial tracking capabilities of GPS, resulting in less precise irrigation patterns and potentially higher water usage compared to GPS-integrated center pivots.

Chemigation Compatibility

Center pivot irrigation systems offer superior chemigation compatibility due to their precise application and centralized control, enabling efficient distribution of fertilizers and pesticides across circular fields. In contrast, lateral move systems, while effective for rectangular fields, generally provide less uniform chemigation application and require more complex equipment to manage chemical injection.

Energy Efficiency Metrics

Center pivot irrigation systems typically consume less energy per acre compared to lateral move systems due to their circular coverage and reduced pipe friction losses. Energy efficiency metrics show center pivots achieve higher uniformity and lower operational pressure requirements, resulting in cost savings and sustainable water use.

Center Pivot vs Lateral Move for Field Irrigation Infographic

agridif.com

agridif.com