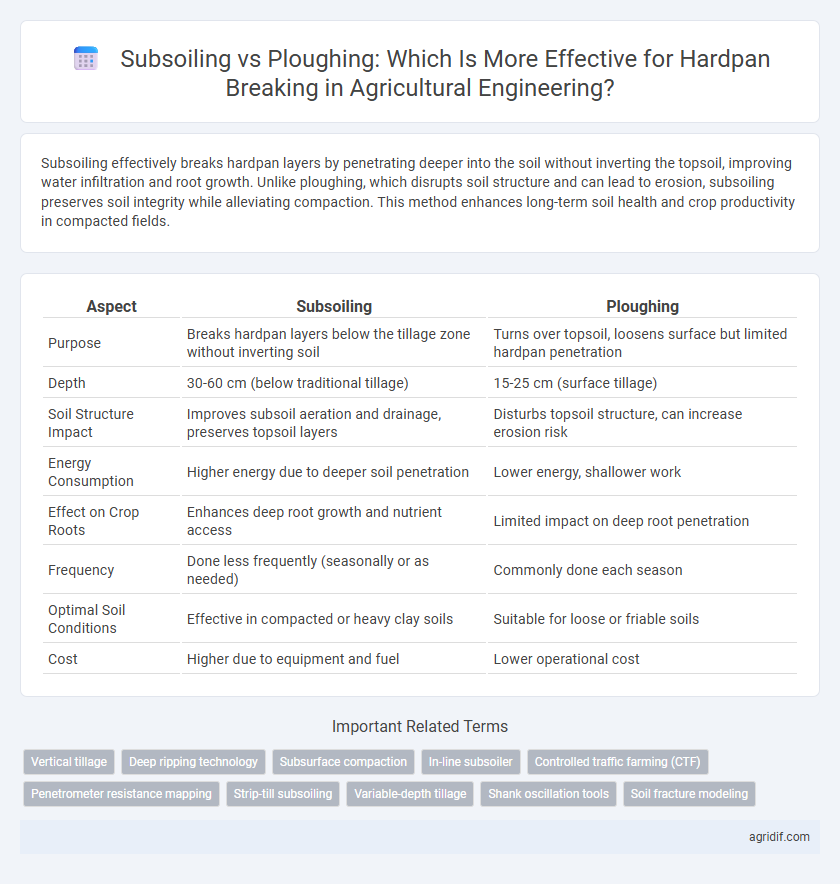

Subsoiling effectively breaks hardpan layers by penetrating deeper into the soil without inverting the topsoil, improving water infiltration and root growth. Unlike ploughing, which disrupts soil structure and can lead to erosion, subsoiling preserves soil integrity while alleviating compaction. This method enhances long-term soil health and crop productivity in compacted fields.

Table of Comparison

| Aspect | Subsoiling | Ploughing |

|---|---|---|

| Purpose | Breaks hardpan layers below the tillage zone without inverting soil | Turns over topsoil, loosens surface but limited hardpan penetration |

| Depth | 30-60 cm (below traditional tillage) | 15-25 cm (surface tillage) |

| Soil Structure Impact | Improves subsoil aeration and drainage, preserves topsoil layers | Disturbs topsoil structure, can increase erosion risk |

| Energy Consumption | Higher energy due to deeper soil penetration | Lower energy, shallower work |

| Effect on Crop Roots | Enhances deep root growth and nutrient access | Limited impact on deep root penetration |

| Frequency | Done less frequently (seasonally or as needed) | Commonly done each season |

| Optimal Soil Conditions | Effective in compacted or heavy clay soils | Suitable for loose or friable soils |

| Cost | Higher due to equipment and fuel | Lower operational cost |

Introduction: Understanding Hardpan Formation in Agriculture

Hardpan formation in agricultural soils results from soil compaction caused by repeated machinery traffic and intensive cropping practices, leading to reduced water infiltration and root penetration. Subsoiling breaks these dense soil layers without inverting the soil profile, preserving soil structure while enhancing aeration and moisture retention. Ploughing disrupts the hardpan by overturning the soil but may increase erosion risk and disturb organic matter distribution.

What is Subsoiling? Definition and Mechanism

Subsoiling is a deep tillage practice aimed at breaking the compacted soil layer known as hardpan, which restricts root growth and water infiltration. It involves using specialized equipment called subsoilers or rippers that penetrate beyond the ploughing depth to fracture the hardpan without inverting the soil. This mechanical disruption improves soil aeration, enhances root penetration, and promotes better water movement in the subsoil, ultimately boosting crop productivity.

Ploughing Explained: Traditional Soil Preparation

Ploughing involves turning over the topsoil to a depth of 15-30 cm, effectively breaking surface compaction but often failing to penetrate hardpan layers deeper than 30 cm. This traditional soil preparation method improves aeration and root penetration in the topsoil but may require repeated passes or complementary techniques to address subsoil hardpan. Compared to subsoiling, ploughing disrupts soil structure more intensively, potentially leading to faster moisture loss and erosion in some agricultural settings.

Comparing Efficiency: Subsoiling vs Ploughing for Hardpan Disruption

Subsoiling penetrates deeper soil layers, effectively breaking compacted hardpan without inverting soil strata, which preserves soil structure and enhances water infiltration. Ploughing primarily disrupts upper soil layers, often leading to soil erosion and reduced moisture retention due to the inversion process. Studies indicate subsoiling improves root growth and crop yield more efficiently in hardpan-affected soils compared to conventional ploughing methods.

Impact on Soil Structure and Crop Yield

Subsoiling penetrates compacted hardpan layers without inverting the soil, preserving soil structure and enhancing water infiltration and root growth, which leads to improved crop yields in heavy soils. Ploughing disrupts soil aggregates and can cause structural degradation over time, potentially reducing soil aeration and moisture retention despite temporarily loosening the soil. Studies indicate subsoiling offers longer-term benefits for soil health and sustained yield increases by maintaining optimal root zone conditions compared to conventional ploughing methods.

Energy, Cost, and Equipment Considerations

Subsoiling effectively breaks hardpan layers with lower energy consumption compared to traditional ploughing, reducing fuel costs and soil compaction. Equipment for subsoiling typically includes deep-tillage shanks designed to penetrate beyond the plough layer, requiring less horsepower than conventional ploughs, which demand more power and frequent maintenance. Choosing subsoiling over ploughing can optimize operational costs by minimizing energy use while enhancing soil structure for improved crop yield.

Environmental Implications: Soil Health and Erosion

Subsoiling effectively breaks hardpan layers without inverting soil, preserving soil structure and reducing erosion risks compared to ploughing. Ploughing disrupts soil aggregates and exposes soil to wind and water erosion, leading to nutrient loss and degradation of soil health. Implementing subsoiling enhances water infiltration, promotes root growth, and maintains microbial activity vital for sustainable agriculture.

Suitable Conditions for Subsoiling and Ploughing

Subsoiling is most suitable for dry, compacted soils with a hardpan layer located 12 to 18 inches below the surface, where deep tillage can improve root penetration and water infiltration without excessive soil disturbance. Ploughing is preferable for soils with loose or moderately compacted top layers, especially when surface residue needs inversion and aeration is required to prepare a seedbed. Selecting subsoiling or ploughing depends on soil moisture, compaction depth, and the presence of surface residues to maximize crop yield potential and maintain soil structure.

Practical Guidelines for Choosing the Right Method

Subsoiling penetrates deeper soil layers, breaking hardpans without inverting the soil, preserving soil structure and moisture retention critical for crop growth. Ploughing effectively aerates the topsoil but may compact lower layers, making it suitable for moderate hardpan issues in loamy soils. Choosing between subsoiling and ploughing should consider soil type, hardpan depth, crop requirements, and tractor power capacity to optimize root development and yield.

Future Trends in Hardpan Breaking Technologies

Future trends in hardpan breaking technologies emphasize precision subsoiling techniques combined with GPS-guided machinery to enhance soil aeration while minimizing energy consumption. Innovations in electro-mechanical subsoilers and sensor-integrated ploughs enable targeted disruption of compacted soil layers, improving root penetration without excessive soil disturbance. Integration of AI-driven soil condition monitoring systems offers real-time adjustment capabilities, optimizing hardpan breaking efficacy and promoting sustainable agricultural productivity.

Related Important Terms

Vertical tillage

Vertical tillage using subsoiling methods effectively breaks hardpan layers without inverting the soil, preserving soil structure and moisture content, unlike traditional ploughing which disrupts soil horizons and increases erosion risk. Subsoiling's deep-reaching shanks penetrate compacted layers, enhancing root growth and nutrient uptake, optimizing crop yields and soil health in sustainable farming systems.

Deep ripping technology

Deep ripping technology effectively breaks hardpan layers below plough depth, enhancing soil aeration and water infiltration more efficiently than traditional ploughing. Subsoiling with deep rippers minimizes soil disturbance while improving root penetration and crop yield potential in compacted soils.

Subsurface compaction

Subsoiling effectively breaks subsurface compaction by penetrating deeper soil layers beyond the reach of traditional ploughing, enhancing root growth and water infiltration. Unlike ploughing, which primarily disturbs the topsoil, subsoiling mitigates hardpan formation without inverting soil layers, preserving soil structure and promoting long-term soil health.

In-line subsoiler

In-line subsoilers effectively break hardpan layers by penetrating deeply without inverting soil, preserving soil structure and moisture retention compared to traditional ploughing. This targeted soil loosening enhances root growth, improves water infiltration, and reduces compaction problems commonly associated with ploughing.

Controlled traffic farming (CTF)

Subsoiling penetrates hardpan layers more effectively than ploughing by breaking compacted soil below the usual tillage depth, enhancing root growth and water infiltration in Controlled Traffic Farming (CTF) systems. CTF concentrates machinery traffic on permanent lanes, reducing soil compaction outside these zones and maximizing the benefits of subsoiling for long-term soil structure improvement.

Penetrometer resistance mapping

Subsoiling significantly reduces penetrometer resistance in compacted soil layers compared to traditional ploughing, enhancing root penetration and water infiltration. Penetrometer resistance mapping reveals that subsoilers break the hardpan more effectively, improving soil structure and crop yield potential.

Strip-till subsoiling

Strip-till subsoiling targets hardpan breaking by creating narrow tilled strips that improve soil aeration and water infiltration while preserving residue cover to reduce erosion. Compared to traditional ploughing, strip-till subsoiling minimizes soil disturbance, enhances root penetration, and promotes more efficient nutrient uptake, resulting in better crop growth and reduced compaction.

Variable-depth tillage

Variable-depth tillage enables targeted hardpan breaking by adjusting subsoiler depth according to soil compaction layers, enhancing root penetration and water infiltration more efficiently than uniform ploughing. Research shows that subsoiling at variable depths reduces soil disruption and conserves moisture while improving crop yield compared to traditional ploughing methods that often invert soil and exacerbate compaction below consistent depths.

Shank oscillation tools

Shank oscillation tools in subsoiling provide efficient hardpan breaking by minimizing soil disturbance and preserving soil structure compared to traditional ploughing methods, which often lead to compaction and reduced aeration. These oscillating subsoiler shanks penetrate deeper, enhancing root growth and water infiltration while reducing fuel consumption and soil erosion risks.

Soil fracture modeling

Subsoiling generates deeper and more uniform soil fractures compared to ploughing, effectively disrupting hardpan layers and enhancing root penetration, which is supported by advanced soil fracture modeling using finite element analysis. Modeling results demonstrate that subsoiling induces tensile stresses that exceed the soil's fracture threshold at greater depths, promoting long-term soil structure improvement and increased water infiltration.

Subsoiling vs Ploughing for hardpan breaking Infographic

agridif.com

agridif.com