Flat fan nozzles produce a uniform, wide spray pattern ideal for applying herbicides and pesticides evenly across field crops, ensuring effective coverage and minimal drift. Hollow cone nozzles generate a circular, finer droplet spray that penetrates dense foliage, making them suitable for fungicide applications where thorough leaf coverage is essential. Selecting between flat fan and hollow cone nozzles depends on the target crop, spray material, and desired droplet size to optimize agrochemical efficiency and reduce environmental impact.

Table of Comparison

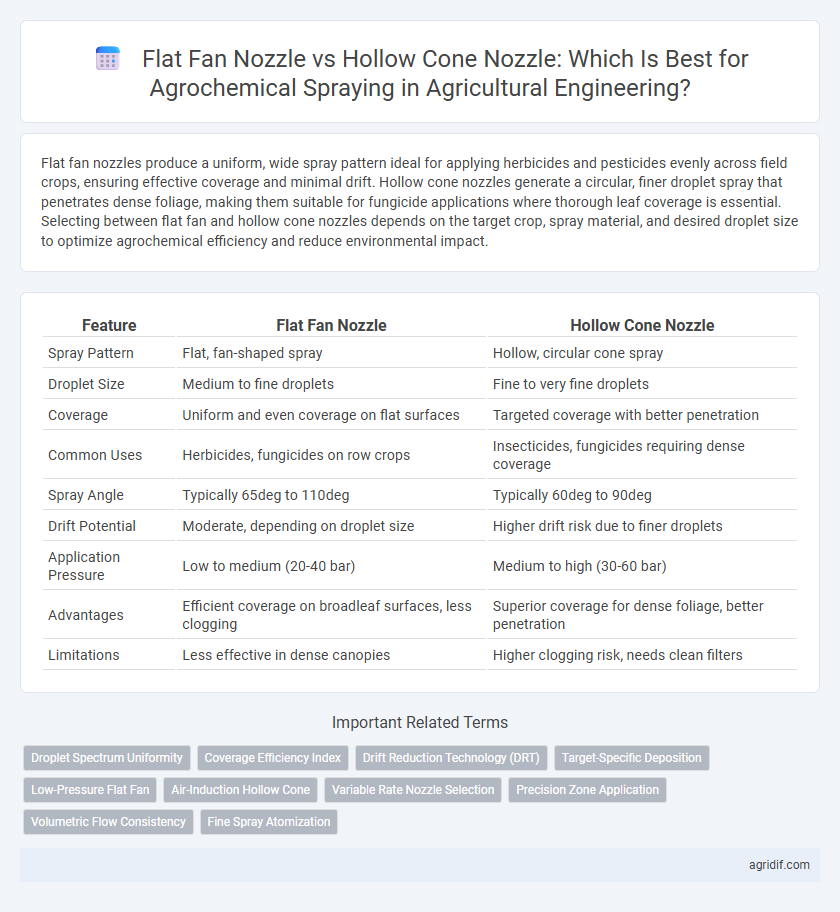

| Feature | Flat Fan Nozzle | Hollow Cone Nozzle |

|---|---|---|

| Spray Pattern | Flat, fan-shaped spray | Hollow, circular cone spray |

| Droplet Size | Medium to fine droplets | Fine to very fine droplets |

| Coverage | Uniform and even coverage on flat surfaces | Targeted coverage with better penetration |

| Common Uses | Herbicides, fungicides on row crops | Insecticides, fungicides requiring dense coverage |

| Spray Angle | Typically 65deg to 110deg | Typically 60deg to 90deg |

| Drift Potential | Moderate, depending on droplet size | Higher drift risk due to finer droplets |

| Application Pressure | Low to medium (20-40 bar) | Medium to high (30-60 bar) |

| Advantages | Efficient coverage on broadleaf surfaces, less clogging | Superior coverage for dense foliage, better penetration |

| Limitations | Less effective in dense canopies | Higher clogging risk, needs clean filters |

Overview of Nozzle Types in Agricultural Spraying

Flat fan nozzles produce a uniform, flat spray pattern ideal for low to medium volume applications, promoting even coverage and minimizing drift in agrochemical spraying. Hollow cone nozzles generate a circular spray pattern with fine droplets, enhancing penetration and coverage on dense crop canopies, making them suitable for fungicides and insecticides. Choosing between flat fan and hollow cone nozzles depends on target crop type, spray volume, and desired droplet size to optimize pesticide efficiency and reduce environmental impact.

Flat Fan Nozzle: Design and Spray Characteristics

Flat fan nozzles feature a narrow, fan-shaped spray pattern that ensures uniform coverage and precise application of agrochemicals, reducing drift and waste. The design includes a flat orifice that creates a thin, fan-shaped spray with medium to fine droplet sizes ideal for targeting specific areas and improving pesticide efficiency. Their spray characteristics provide consistent overlap, leading to even distribution and better pest control in row crops and orchards.

Hollow Cone Nozzle: Structure and Atomization Features

Hollow cone nozzles feature a conical spray pattern that produces fine droplets ideal for uniform coverage in agrochemical applications. Their design incorporates a swirl chamber that imparts rotational force to the liquid, enhancing atomization and creating a hollow circular spray for improved penetration. This structure ensures efficient pesticide distribution while minimizing drift and waste during agricultural spraying.

Droplet Size and Distribution: Flat Fan vs Hollow Cone

Flat fan nozzles produce uniform, medium-sized droplets ideal for even coverage on flat surfaces, minimizing drift and maximizing spray efficiency. Hollow cone nozzles generate finer droplets with a wider distribution pattern, enhancing penetration in dense crops but increasing drift potential. Selecting between flat fan and hollow cone nozzles depends on balancing droplet size for target coverage and minimizing off-target movement in agrochemical spraying.

Coverage Efficiency in Crop Canopies

Flat fan nozzles provide uniform, wide coverage ideal for dense crop canopies, ensuring even distribution of agrochemicals with minimal overlap. Hollow cone nozzles generate finer droplets and a circular spray pattern, improving penetration in taller or irregular canopies but may cause drift and uneven coverage at varying heights. Optimal coverage efficiency depends on canopy structure, spray volume, and droplet size, with flat fan nozzles favored for broad, uniform coverage and hollow cone nozzles suited for targeted penetration.

Drift Potential and Environmental Impact Comparison

Flat fan nozzles generally produce larger droplets that reduce drift potential, minimizing off-target movement of agrochemicals and lowering environmental contamination risks. In contrast, hollow cone nozzles generate finer droplets that improve coverage but increase drift potential, potentially leading to greater atmospheric dispersion and environmental harm. Selecting flat fan nozzles optimizes spray efficiency by balancing effective application with reduced environmental impact.

Suitable Applications: Herbicide, Fungicide, and Insecticide Spraying

Flat fan nozzles provide uniform coverage and are ideal for herbicide applications, ensuring even distribution across broadleaf weeds. Hollow cone nozzles produce a finer spray pattern suited for fungicide and insecticide treatments, enabling better penetration and coverage on dense foliage. Selecting the appropriate nozzle type improves pesticide efficacy and reduces chemical waste in agricultural spraying.

Pressure Requirements and Operating Conditions

Flat fan nozzles typically operate efficiently at lower pressures, around 20-40 psi, providing uniform spray patterns ideal for herbicide applications. Hollow cone nozzles require higher pressures, usually between 40-70 psi, to generate a fine droplet size suitable for fungicide and insecticide sprays. The choice between these nozzles depends on specific crop protection needs and environmental conditions, as pressure impacts droplet size, coverage, and drift potential.

Maintenance, Clogging, and Durability Aspects

Flat fan nozzles typically require less maintenance due to their simpler design and are less prone to clogging, making them suitable for spraying agrochemicals with lower viscosity or particulates. Hollow cone nozzles, while providing better coverage in dense canopies, are more susceptible to clogging and demand frequent cleaning and inspection to maintain durability and spray efficacy. Optimal nozzle selection balances the ease of maintenance and clog resistance with the durability needed for specific agrochemical formulations and field conditions.

Selecting the Right Nozzle for Optimal Spraying Performance

Flat fan nozzles deliver a uniform, fan-shaped spray pattern ideal for herbicide applications, providing excellent coverage and minimizing drift. Hollow cone nozzles produce a circular spray pattern with finer droplets suited for fungicides and insecticides, ensuring thorough canopy penetration and better target coverage. Selecting the right nozzle depends on the type of agrochemical, crop structure, and environmental conditions to maximize efficacy and reduce chemical waste.

Related Important Terms

Droplet Spectrum Uniformity

Flat fan nozzles produce a narrower droplet size distribution, enhancing droplet spectrum uniformity for precise agrochemical application and reduced drift. In contrast, hollow cone nozzles generate a wider range of droplet sizes, leading to less uniform coverage but improved penetration in dense canopies.

Coverage Efficiency Index

Flat fan nozzles deliver a uniform spray pattern with a higher Coverage Efficiency Index, ensuring more consistent agrochemical deposition across crop surfaces. Hollow cone nozzles produce a circular, mist-like spray with lower coverage efficiency but better penetration in dense canopies, making them suitable for targeted spraying.

Drift Reduction Technology (DRT)

Flat fan nozzles with Drift Reduction Technology (DRT) deliver larger droplets and a more uniform spray pattern, significantly minimizing off-target drift in agrochemical applications. Hollow cone nozzles typically produce finer droplets that increase drift potential, making flat fan nozzles the preferred choice for precise pesticide placement and environmental safety.

Target-Specific Deposition

Flat fan nozzles deliver uniform, targeted spray patterns ideal for precise agrochemical application on row crops, minimizing drift and improving deposition efficiency on leaf surfaces. Hollow cone nozzles produce a circular spray pattern with finer droplets, enhancing coverage for dense canopies but potentially increasing off-target drift due to smaller droplet size and broader dispersion.

Low-Pressure Flat Fan

Low-pressure flat fan nozzles deliver uniform spray coverage with a wide, flat pattern ideal for herbicide applications, minimizing drift and ensuring efficient chemical use. Compared to hollow cone nozzles, which produce finer droplets and are better suited for fungicides and insecticides, flat fan nozzles maintain lower spray angles and larger droplet sizes, enhancing penetration and reducing evaporation on target crops.

Air-Induction Hollow Cone

Air-induction hollow cone nozzles generate coarse droplets with air bubbles that reduce drift and improve deposition efficiency, making them ideal for agrochemical spraying in windy conditions. These nozzles create a uniform spray pattern with enhanced coverage, optimizing chemical use and minimizing environmental impact compared to flat fan nozzles.

Variable Rate Nozzle Selection

Flat fan nozzles deliver uniform spray distribution ideal for uniform crop canopies, while hollow cone nozzles provide better coverage for dense foliage due to their circular spray pattern. Selecting variable rate nozzles depends on factors such as target crop structure, desired droplet size, and application rate to optimize agrochemical efficiency and minimize drift.

Precision Zone Application

Flat fan nozzles provide a uniform spray pattern ideal for precision zone application, ensuring accurate coverage and reduced drift in targeted areas. Hollow cone nozzles generate a circular spray with finer droplets, enhancing penetration for dense crops but may result in less uniformity compared to flat fan nozzles in precision spraying tasks.

Volumetric Flow Consistency

Flat fan nozzles deliver a more uniform volumetric flow rate, ensuring consistent application of agrochemicals across targeted areas, while hollow cone nozzles tend to produce variable flow patterns that can impact spray coverage uniformity. Precise flow consistency in flat fan nozzles enhances spray efficiency and reduces chemical waste, making them preferred for uniform field applications.

Fine Spray Atomization

Flat fan nozzles produce a uniform, fine spray atomization ideal for precise agrochemical application, enhancing coverage and minimizing drift. Hollow cone nozzles create a circular spray pattern with coarser droplets, which can reduce drift but may compromise fine coverage critical for effective pest control.

Flat fan nozzle vs hollow cone nozzle for agrochemical spraying Infographic

agridif.com

agridif.com