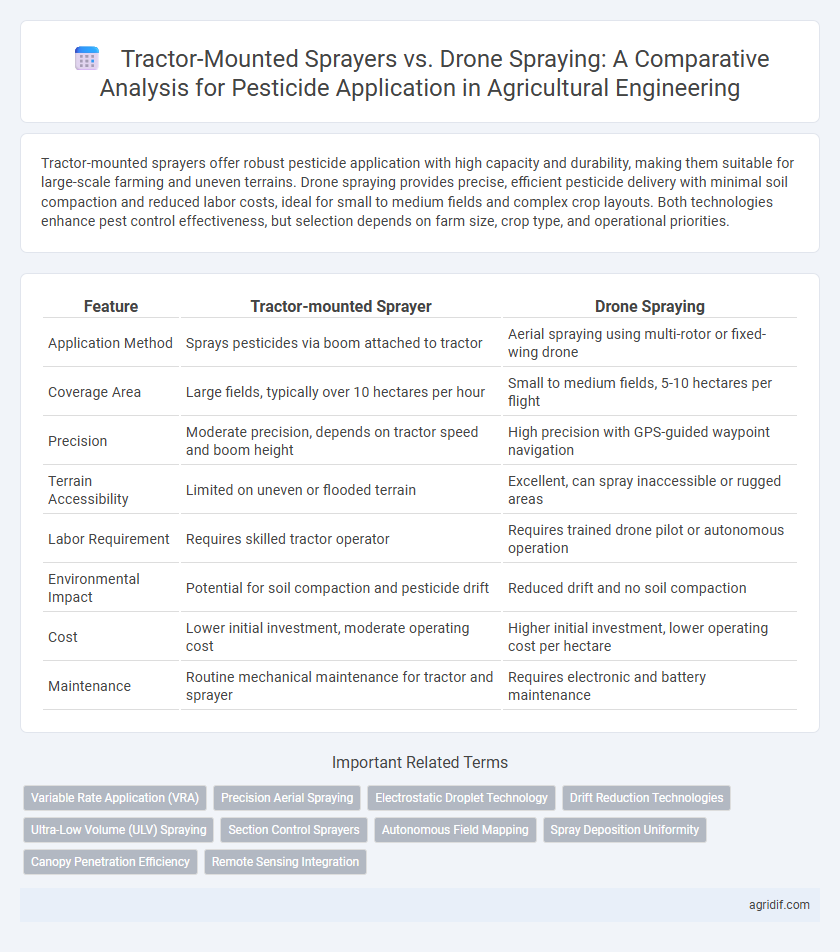

Tractor-mounted sprayers offer robust pesticide application with high capacity and durability, making them suitable for large-scale farming and uneven terrains. Drone spraying provides precise, efficient pesticide delivery with minimal soil compaction and reduced labor costs, ideal for small to medium fields and complex crop layouts. Both technologies enhance pest control effectiveness, but selection depends on farm size, crop type, and operational priorities.

Table of Comparison

| Feature | Tractor-mounted Sprayer | Drone Spraying |

|---|---|---|

| Application Method | Sprays pesticides via boom attached to tractor | Aerial spraying using multi-rotor or fixed-wing drone |

| Coverage Area | Large fields, typically over 10 hectares per hour | Small to medium fields, 5-10 hectares per flight |

| Precision | Moderate precision, depends on tractor speed and boom height | High precision with GPS-guided waypoint navigation |

| Terrain Accessibility | Limited on uneven or flooded terrain | Excellent, can spray inaccessible or rugged areas |

| Labor Requirement | Requires skilled tractor operator | Requires trained drone pilot or autonomous operation |

| Environmental Impact | Potential for soil compaction and pesticide drift | Reduced drift and no soil compaction |

| Cost | Lower initial investment, moderate operating cost | Higher initial investment, lower operating cost per hectare |

| Maintenance | Routine mechanical maintenance for tractor and sprayer | Requires electronic and battery maintenance |

Introduction to Modern Pesticide Application Methods

Tractor-mounted sprayers provide consistent pesticide application with high payload capacity, suitable for large-scale farms and versatile terrain. Drone spraying offers precision targeting, reduced chemical use, and access to difficult areas, enhancing efficiency in orchards and irregular fields. Integration of GPS and sensor technologies in both methods improves accuracy and minimizes environmental impact.

Overview of Tractor-Mounted Sprayers

Tractor-mounted sprayers offer high pesticide application capacity, efficiently covering large agricultural fields with uniform spray distribution using boom arms and calibrated nozzles. These sprayers are suitable for various crop types and can handle diverse pesticide formulations, ensuring effective pest control while minimizing hose and pump wear. Their integration with GPS technology enhances precision farming by optimizing spray patterns and reducing chemical waste.

Advancements in Drone Spraying Technology

Advancements in drone spraying technology have revolutionized pesticide application with precise, GPS-guided systems that optimize coverage and reduce chemical waste. Unlike traditional tractor-mounted sprayers, drones can access difficult terrain and apply pesticides at variable heights, increasing efficiency and minimizing crop damage. Enhanced sensors and AI integration allow for real-time monitoring and adaptive spraying, significantly improving pest control outcomes in modern agricultural practices.

Comparative Efficiency: Coverage and Precision

Tractor-mounted sprayers offer consistent pesticide coverage over large fields with precise control of spray volume and droplet size, ensuring uniform application on crops. Drone spraying enables targeted, high-precision pesticide delivery in hard-to-reach areas, reducing chemical use and minimizing environmental impact through GPS-guided navigation and variable rate technology. Comparing efficiency, drones excel in precision and adaptability for complex terrains, while tractor sprayers provide faster coverage for vast, flat agricultural landscapes.

Cost Analysis: Initial Investment and Operating Expenses

Tractor-mounted sprayers require a higher initial investment, often ranging from $5,000 to $15,000, but benefit from lower operating costs due to readily available fuel and maintenance services. Drone spraying systems involve a significant upfront cost, typically between $10,000 and $30,000, with additional expenses for batteries, software updates, and skilled labor. Over time, tractor-mounted sprayers offer cost efficiency for large-scale farms, while drones provide precise pesticide application that can reduce chemical usage and long-term operating costs on smaller or irregularly shaped fields.

Impact on Crop Health and Yield

Tractor-mounted sprayers provide uniform pesticide application with deep canopy penetration, enhancing crop protection and promoting higher yield consistency in large, flat fields. Drone spraying offers precision targeting and minimal soil compaction, reducing plant stress and improving overall crop health, especially in irregular terrain or small plots. Integrating advanced GPS and sensor technologies in both methods optimizes pesticide distribution, minimizing chemical waste and maximizing crop productivity.

Environmental Considerations and Drift Control

Tractor-mounted sprayers offer targeted pesticide application with moderate drift control through adjustable nozzles and boom height, reducing off-target contamination but potentially disturbing soil and crops. Drone spraying enhances environmental safety by enabling precise, low-volume spray delivery at variable altitudes, minimizing pesticide drift and runoff in uneven or sensitive terrains. Both methods require careful calibration and timing to optimize drift control and limit environmental impact on non-target organisms and water resources.

Labor Requirements and Safety Factors

Tractor-mounted sprayers demand significant labor for operation, requiring trained drivers and manual setup, while drone spraying reduces labor by enabling remote, automated pesticide application with minimal human intervention. Safety risks in tractor-mounted spraying include operator exposure to chemicals and physical hazards from equipment, whereas drones minimize direct contact, enhancing operator safety by allowing pesticide dispersal from a distance. The shift to drone spraying also reduces soil compaction and crop damage linked to heavy machinery movement, improving overall field safety and sustainability in agricultural practices.

Suitability for Different Farm Sizes and Terrains

Tractor-mounted sprayers are highly effective for large, flat farms with extensive crop areas, offering robust pesticide application and greater liquid capacity. Drone spraying excels in small to medium-sized farms, especially those with uneven or hilly terrains, providing precision targeting and reduced soil compaction. Farm size and topography significantly influence the choice, with drones preferred for difficult terrains and tractors suited to large-scale, uniform fields.

Future Trends in Agricultural Spraying Technology

Tractor-mounted sprayers offer precise pesticide application with high capacity but face limitations in accessibility on uneven terrain and smaller plots, prompting innovation in autonomous guidance and variable rate technology. Drone spraying advances include enhanced GPS navigation, AI-based target recognition, and multispectral sensors allowing precise, environmentally friendly applications, especially in hilly or fragmented landscapes. Future trends highlight integration of IoT and machine learning for real-time monitoring and adaptive spraying, promoting sustainable pest management and reducing chemical usage in agriculture.

Related Important Terms

Variable Rate Application (VRA)

Tractor-mounted sprayers equipped with Variable Rate Application (VRA) technology offer precise pesticide delivery by adjusting spray rates based on real-time field data, improving efficiency and reducing chemical waste. Drone spraying enhances VRA by enabling targeted application in difficult terrains and small plots, leveraging GPS and sensor technology for site-specific treatment and minimizing environmental impact.

Precision Aerial Spraying

Tractor-mounted sprayers apply pesticides through ground-level nozzles, offering uniform coverage but limited reach in uneven or dense terrains, whereas drone spraying provides precision aerial spraying with GPS-guided targeting, minimizing chemical use and reducing environmental impact. Drone technology enables real-time monitoring and variable rate application, enhancing efficiency and crop health management in modern agricultural practices.

Electrostatic Droplet Technology

Tractor-mounted sprayers equipped with electrostatic droplet technology enhance pesticide adherence by charging droplets, improving coverage on crop surfaces and reducing chemical runoff. Drone spraying leverages this technology to access difficult terrain with precision, optimizing droplet distribution and minimizing environmental impact while increasing operational efficiency in pesticide application.

Drift Reduction Technologies

Tractor-mounted sprayers equipped with low-drift nozzles and air-induction technology reduce pesticide drift by producing larger, heavier droplets that settle quickly, minimizing off-target contamination. Drone spraying utilizes precision GPS-guided systems and adjustable nozzles to regulate droplet size and spray pattern, effectively decreasing drift over uneven terrain and sensitive crop areas.

Ultra-Low Volume (ULV) Spraying

Tractor-mounted sprayers deliver consistent Ultra-Low Volume (ULV) pesticide applications with high capacity and coverage but face limitations in maneuverability and terrain accessibility. Drone spraying offers precise ULV application with minimal pesticide use, increased efficiency in difficult terrains, and reduced environmental drift, revolutionizing targeted pest control in modern agriculture.

Section Control Sprayers

Tractor-mounted sprayers with advanced section control systems enable precise pesticide application by selectively activating spray nozzles based on GPS mapping, reducing chemical waste and environmental impact. Drone spraying technology integrates similar section control features with real-time data, offering high maneuverability and coverage efficiency in difficult terrains, enhancing targeted pest management in modern agricultural engineering.

Autonomous Field Mapping

Tractor-mounted sprayers rely on GPS-guided autonomous field mapping systems to precisely target pesticide application, optimizing coverage and minimizing chemical waste. Drone spraying enhances autonomous field mapping by integrating high-resolution sensors and real-time data analytics, enabling variable rate application and access to difficult terrains for improved pest control efficiency.

Spray Deposition Uniformity

Tractor-mounted sprayers often provide more consistent spray deposition uniformity due to their direct nozzle placement and controlled ground speed, ensuring precise pesticide coverage on crops. Drone spraying, while offering flexibility and access to difficult terrain, can present variability in spray deposition caused by wind drift and altitude fluctuations, potentially reducing uniformity in pesticide application.

Canopy Penetration Efficiency

Tractor-mounted sprayers deliver pesticides with strong canopy penetration due to higher liquid volume and pressure, effectively reaching lower foliage in dense crops. Drone spraying relies on precise aerial application and droplet size control but may struggle with deep canopy penetration, making it more suitable for uniform or sparse canopies.

Remote Sensing Integration

Tractor-mounted sprayers equipped with GPS and multispectral sensors enable precise pesticide application through real-time remote sensing data integration, optimizing spray patterns and reducing chemical waste on large-scale farms. Drone spraying leverages advanced remote sensing technologies such as hyperspectral imaging and LiDAR to provide targeted, high-resolution crop health monitoring, facilitating variable rate application with enhanced accuracy and minimal environmental impact.

Tractor-mounted sprayer vs Drone spraying for pesticide application Infographic

agridif.com

agridif.com