PTO-driven pumps are powered directly by the tractor's power take-off, offering greater portability and ease of setup for small to medium-scale irrigation systems. Engine-driven pumps operate independently, providing consistent flow rates and higher pressure suitable for large-scale or remote irrigation where tractor use is impractical. Choosing between PTO-driven and engine-driven pumps depends on factors such as irrigation area size, fuel efficiency, and operational flexibility.

Table of Comparison

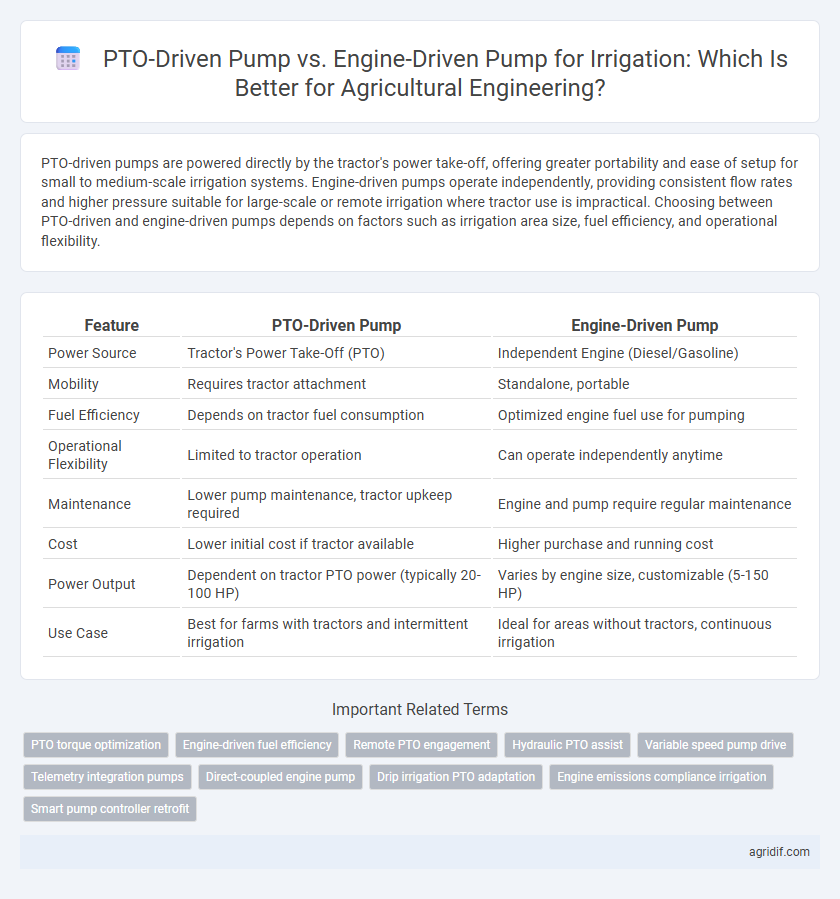

| Feature | PTO-Driven Pump | Engine-Driven Pump |

|---|---|---|

| Power Source | Tractor's Power Take-Off (PTO) | Independent Engine (Diesel/Gasoline) |

| Mobility | Requires tractor attachment | Standalone, portable |

| Fuel Efficiency | Depends on tractor fuel consumption | Optimized engine fuel use for pumping |

| Operational Flexibility | Limited to tractor operation | Can operate independently anytime |

| Maintenance | Lower pump maintenance, tractor upkeep required | Engine and pump require regular maintenance |

| Cost | Lower initial cost if tractor available | Higher purchase and running cost |

| Power Output | Dependent on tractor PTO power (typically 20-100 HP) | Varies by engine size, customizable (5-150 HP) |

| Use Case | Best for farms with tractors and intermittent irrigation | Ideal for areas without tractors, continuous irrigation |

Introduction: PTO-Driven vs Engine-Driven Pumps in Irrigation

PTO-driven pumps utilize the power take-off from tractors to operate irrigation systems, offering flexibility and reduced initial investment for varying field sizes. Engine-driven pumps rely on dedicated motors, providing consistent power output and higher efficiency for extensive irrigation needs. Understanding the trade-offs in fuel consumption, maintenance, and operational control aids in selecting the optimal pump system for specific agricultural applications.

System Design and Components Overview

PTO-driven pumps utilize the tractor's power take-off as the energy source, integrating seamlessly with existing agricultural machinery for efficient irrigation system design. Engine-driven pumps feature standalone power units, offering independent operation and flexible placement in irrigation setups but requiring additional fuel and maintenance management. Optimal system design balances tractor availability, energy efficiency, and irrigation scale to select the appropriate pump type and components.

Energy Source and Power Requirements

PTO-driven pumps utilize the tractor's power take-off system, offering efficient energy transfer directly from the engine, ideal for moderate irrigation demands with variable power needs. Engine-driven pumps operate independently with their own fuel-powered engines, providing consistent and higher output suitable for large-scale irrigation requiring substantial energy input. Energy source choice impacts fuel consumption, maintenance, and operational flexibility, with PTO pumps relying on tractor fuel and engine-driven pumps necessitating separate fuel management.

Installation and Setup Considerations

PTO-driven pumps typically require compatibility with tractor PTO specifications and precise alignment for efficient power transfer, making installation more complex but allowing easy detachment when not in use. Engine-driven pumps offer standalone operation with simpler setup focused on fuel and exhaust management, suitable for locations without available tractors. Proper foundation and vibration isolation are critical in both cases to ensure stable operation and minimize maintenance.

Operational Efficiency and Performance

PTO-driven pumps typically offer higher operational efficiency by directly utilizing tractor power, resulting in lower fuel consumption and reduced mechanical losses compared to engine-driven pumps. Engine-driven pumps provide consistent performance independent of tractor operation, allowing continuous irrigation and versatility in varying field conditions. Both systems require careful matching of pump capacity to irrigation needs to maximize water delivery and minimize energy expenditure.

Maintenance Needs and Longevity

PTO-driven pumps require regular inspection of the power take-off shaft, coupling, and driveline to prevent wear and ensure efficient power transfer, with maintenance typically involving lubrication and alignment checks. Engine-driven pumps often demand more frequent engine servicing, including oil changes, air filter replacements, and cooling system maintenance, which can increase downtime. PTO-driven pumps generally offer longer operational life due to fewer standalone mechanical components and the ability to share maintenance schedules with the tractor, whereas engine-driven pumps may face faster wear from continuous engine load and more complex repairs.

Cost Analysis: Initial Investment and Operating Expenses

PTO-driven pumps typically have a lower initial investment due to compatibility with existing tractor systems, reducing equipment purchase costs. Engine-driven pumps involve higher upfront expenses but offer greater operational independence and flexibility in irrigation scheduling. Operating expenses for PTO-driven pumps may be lower when leveraging the tractor's multi-purpose use, whereas engine-driven pumps incur separate fuel and maintenance costs, impacting long-term financial efficiency.

Adaptability and Flexibility in Field Operations

PTO-driven pumps offer superior adaptability by utilizing the tractor's power source, allowing seamless integration across various field conditions and equipment setups. Engine-driven pumps provide independent operation but may lack the flexibility to adjust quickly to changing field requirements or tractor compatibility. For dynamic irrigation needs, PTO-driven pumps enhance operational flexibility, reducing downtime and improving resource efficiency in diverse agricultural environments.

Environmental Impact and Fuel Consumption

PTO-driven pumps typically offer higher fuel efficiency by utilizing the tractor's existing power source, thereby reducing overall fuel consumption and emissions compared to engine-driven pumps that rely on separate fuel sources. Engine-driven pumps often produce higher greenhouse gas emissions due to independent fuel combustion, increasing the environmental footprint of irrigation practices. Choosing PTO-driven systems can lead to more sustainable water management by minimizing fuel use and associated environmental impacts in agricultural irrigation.

Suitability for Different Farm Scales and Cropping Systems

PTO-driven pumps are highly suitable for medium to large-scale farms with tractor availability, offering flexibility in powering irrigation systems across diverse cropping patterns such as row crops and orchards. Engine-driven pumps provide an independent, reliable irrigation source ideal for small to medium-scale farms, especially in areas lacking tractors or where diverse crop rotations require mobile and standalone water supply. Selecting the appropriate pump depends on farm size, crop type, irrigation frequency, and access to machinery, ensuring optimized water management and energy efficiency.

Related Important Terms

PTO torque optimization

PTO-driven pumps optimize irrigation efficiency by utilizing tractor power take-off torque, ensuring precise energy transfer for consistent water flow under varying load conditions. Engine-driven pumps often lack adaptive torque control, resulting in less efficient fuel use and variable performance in dynamic agricultural environments.

Engine-driven fuel efficiency

Engine-driven pumps for irrigation offer superior fuel efficiency by optimizing combustion processes and maintaining consistent power output under variable workloads, reducing fuel consumption compared to PTO-driven pumps. This enhanced fuel economy translates to lower operational costs and increased sustainability for agricultural water management.

Remote PTO engagement

Remote PTO engagement enables precise control of PTO-driven pumps, enhancing operational efficiency and reducing manual labor in irrigation systems. Engine-driven pumps lack this feature, often resulting in less flexibility and higher maintenance demands in agricultural irrigation applications.

Hydraulic PTO assist

Hydraulic PTO assist enhances the efficiency of PTO-driven pumps by reducing engine load and improving fuel economy compared to traditional engine-driven pumps. This technology enables smoother power transfer and greater operational flexibility, optimizing irrigation performance in agricultural engineering applications.

Variable speed pump drive

Variable speed PTO-driven pumps offer enhanced energy efficiency and precise flow control compared to traditional engine-driven pumps, enabling optimized water usage in irrigation systems. This adaptability reduces fuel consumption and mechanical wear, improving overall system sustainability and operational cost-effectiveness in agricultural applications.

Telemetry integration pumps

PTO-driven pumps offer seamless integration with tractor telemetry systems, enabling precise monitoring of hydraulic performance and real-time data analytics for optimized irrigation schedules. Engine-driven pumps, while independent of tractor systems, require standalone telemetry solutions that may lack unified data interfaces, affecting cohesive irrigation management and operational efficiency.

Direct-coupled engine pump

Direct-coupled engine pumps for irrigation offer higher efficiency and reliability by eliminating power losses associated with power-take-off (PTO)-driven pumps, ensuring a consistent flow rate under varying load conditions. They provide better fuel economy and reduced maintenance due to fewer mechanical linkages, making them ideal for continuous use in agricultural irrigation systems.

Drip irrigation PTO adaptation

PTO-driven pumps offer efficient power transfer from tractors, making them ideal for drip irrigation systems that require consistent, low-pressure water flow for precise moisture delivery. Engine-driven pumps provide independent operation but may consume more fuel and require additional maintenance, whereas PTO-driven pumps ensure better fuel efficiency and integration with existing agricultural machinery.

Engine emissions compliance irrigation

Engine-driven pumps for irrigation offer enhanced compliance with stringent engine emissions regulations by integrating advanced catalytic converters and electronic fuel injection systems, reducing nitrogen oxides and particulate matter. This contrasts with PTO-driven pumps, which rely on tractor engines that may not meet the latest emission standards, limiting their environmental sustainability in modern agricultural practices.

Smart pump controller retrofit

PTO-driven pumps offer efficient power transfer from tractors but lack independent control, whereas engine-driven pumps enable precise flow regulation critical for irrigation. Retrofitting with a smart pump controller optimizes irrigation scheduling and energy use by integrating real-time sensor data with pump operation, enhancing water conservation and crop yield.

PTO-driven pump vs engine-driven pump for irrigation Infographic

agridif.com

agridif.com