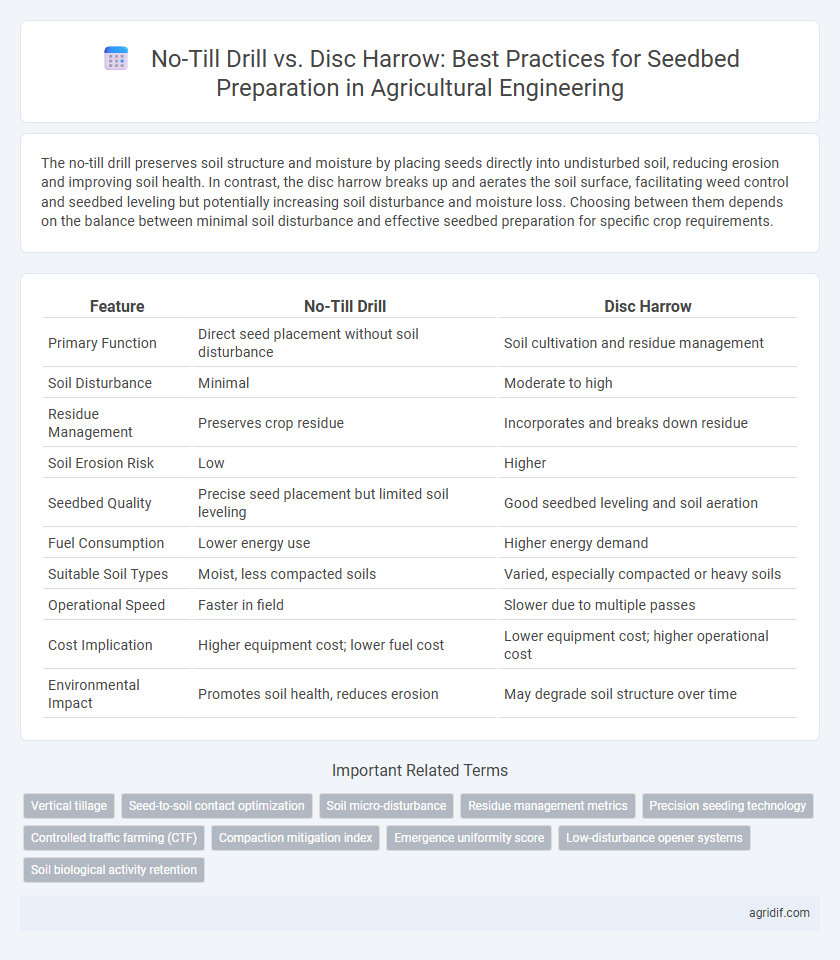

The no-till drill preserves soil structure and moisture by placing seeds directly into undisturbed soil, reducing erosion and improving soil health. In contrast, the disc harrow breaks up and aerates the soil surface, facilitating weed control and seedbed leveling but potentially increasing soil disturbance and moisture loss. Choosing between them depends on the balance between minimal soil disturbance and effective seedbed preparation for specific crop requirements.

Table of Comparison

| Feature | No-Till Drill | Disc Harrow |

|---|---|---|

| Primary Function | Direct seed placement without soil disturbance | Soil cultivation and residue management |

| Soil Disturbance | Minimal | Moderate to high |

| Residue Management | Preserves crop residue | Incorporates and breaks down residue |

| Soil Erosion Risk | Low | Higher |

| Seedbed Quality | Precise seed placement but limited soil leveling | Good seedbed leveling and soil aeration |

| Fuel Consumption | Lower energy use | Higher energy demand |

| Suitable Soil Types | Moist, less compacted soils | Varied, especially compacted or heavy soils |

| Operational Speed | Faster in field | Slower due to multiple passes |

| Cost Implication | Higher equipment cost; lower fuel cost | Lower equipment cost; higher operational cost |

| Environmental Impact | Promotes soil health, reduces erosion | May degrade soil structure over time |

Introduction to No-Till Drill and Disc Harrow

No-till drills enable seed planting directly into undisturbed soil, preserving soil structure and moisture while reducing erosion. Disc harrows, equipped with concave steel discs, break up and smooth the soil surface by cutting and mixing residue, preparing a firm seedbed but with increased soil disturbance. Choosing between no-till drills and disc harrows depends on soil health goals, crop type, and residue management requirements in sustainable agriculture.

Principles of Seedbed Preparation

No-till drills preserve soil structure and moisture by placing seeds directly into undisturbed residue, enhancing soil health and reducing erosion compared to disc harrows, which disrupt soil layers and accelerate moisture loss. The principle of seedbed preparation with no-till drills emphasizes minimal soil disturbance to maintain organic matter and microbial activity, crucial for seed germination and early root growth. Disc harrows create a finer, more uniform seedbed by mechanically breaking clods and incorporating crop residues, improving seed-to-soil contact but at the cost of increased soil compaction and degradation over time.

No-Till Drill: Overview and Working Mechanism

No-till drills prepare seedbeds by creating narrow furrows with minimal soil disturbance, preserving soil structure and moisture. The drill uses coulters and seed openers to place seeds precisely at the desired depth while leaving crop residues intact. This method enhances soil health, reduces erosion, and improves water retention compared to conventional disc harrow practices.

Disc Harrow: Overview and Working Mechanism

Disc harrows consist of concave metal discs arranged in gangs that cut through soil, breaking clods and incorporating residues to create a fine seedbed. This implement effectively aerates the soil, enhances moisture retention, and controls weeds by disturbing the topsoil layer. Its working mechanism relies on the discs' rotation and angled positioning to slice, lift, and turn the soil, optimizing seedbed conditions for various crops.

Soil Disturbance and Structure Preservation

No-till drills minimize soil disturbance by directly placing seeds into undisturbed soil, preserving soil structure and moisture retention critical for sustainable crop growth. Disc harrows, while effective at residue management, disrupt soil layers more extensively, potentially leading to increased erosion and moisture loss. Maintaining soil integrity with no-till technology enhances microbial activity and root development, promoting long-term soil health compared to the aggressive soil turnover caused by disc harrowing.

Impact on Soil Erosion and Moisture Retention

No-till drills minimize soil disturbance by planting seeds directly into undisturbed soil, significantly reducing soil erosion and enhancing moisture retention compared to disc harrows. Disc harrows aggressively till the soil surface, increasing erosion risks and accelerating moisture loss through evaporation. Implementing no-till drills supports sustainable agriculture by preserving soil structure and maintaining higher soil moisture levels critical for crop growth.

Crop Residue Management and Weed Control

No-till drills preserve crop residue on the soil surface, enhancing moisture retention and reducing erosion while providing effective weed control by minimizing soil disturbance. Disc harrows disturb residue, leading to faster decomposition but increased soil erosion risk and potential weed seed exposure that could promote weed emergence. Effective seedbed preparation balances residue management and weed suppression, with no-till drills offering superior conservation benefits compared to disc harrows.

Operational Efficiency and Fuel Requirements

No-till drills significantly enhance operational efficiency by enabling direct seed placement without soil disturbance, reducing field passes and saving time compared to disc harrows. Disc harrows require multiple passes to break up and smooth the soil, leading to higher fuel consumption and increased labor. Fuel requirements for no-till drills are typically 30-50% lower than those of disc harrows due to minimized soil tillage and reduced machinery operation.

Suitability for Different Crops and Field Conditions

No-till drills maintain soil structure and moisture, making them ideal for small grains, legumes, and crops sensitive to soil disturbance in wetter or erosion-prone fields. Disc harrows are better suited for heavier soils and fields with dense residue, providing effective residue chopping and soil aeration for row crops like corn and soybeans. Selecting between no-till drills and disc harrows depends on crop type, soil texture, and residue management needs to optimize seedbed conditions.

Economic Considerations and Long-Term Benefits

No-till drills reduce labor and fuel costs by minimizing soil disturbance, leading to lower operational expenses compared to disc harrows. Over time, no-till systems enhance soil structure and moisture retention, which can increase yield stability and reduce the need for costly inputs such as irrigation and fertilizers. Although disc harrows offer immediate soil aeration benefits, their repetitive use may accelerate soil erosion and degradation, resulting in higher long-term remediation costs.

Related Important Terms

Vertical tillage

No-till drills minimize soil disturbance by placing seeds directly into undisturbed residue, preserving soil structure and moisture, while disc harrows aggressively cut and mix the soil, potentially causing erosion and disrupting soil integrity. Vertical tillage tools provide an intermediate solution by lightly cutting residue and loosening soil vertically to improve seedbed conditions without the intense mixing characteristic of disc harrows.

Seed-to-soil contact optimization

No-till drills enhance seed-to-soil contact by placing seeds directly into undisturbed soil, preserving soil structure and moisture, which improves germination rates and reduces erosion. Disc harrows disturb the soil surface extensively, creating a rougher seedbed that may reduce uniform seed placement and seed-to-soil contact efficiency.

Soil micro-disturbance

The no-till drill preserves soil structure by minimizing micro-disturbance, promoting enhanced microbial activity and moisture retention essential for seed germination. In contrast, the disc harrow disrupts soil micro-aggregates, leading to increased erosion risk and reduced soil biological health during seedbed preparation.

Residue management metrics

No-till drills enhance residue management by minimizing soil disturbance, maintaining over 80% surface residue cover, which reduces erosion and preserves soil organic matter. Disc harrows typically leave less than 50% residue cover, increasing soil exposure and accelerating residue decomposition, which can impact long-term soil health negatively.

Precision seeding technology

No-till drills provide precise seed placement by minimizing soil disturbance, preserving soil structure and moisture, which enhances germination rates and crop uniformity compared to disc harrows that aggressively till and disrupt the seedbed. Precision seeding technology integrated with no-till drills allows for accurate seed depth control and spatial distribution, optimizing plant growth and resource efficiency in sustainable agricultural practices.

Controlled traffic farming (CTF)

No-till drills enhance soil structure preservation and moisture retention by minimizing soil disturbance, aligning effectively with Controlled Traffic Farming (CTF) principles to reduce compaction and maintain consistent traffic lanes. Disc harrows, while effective for residue incorporation and weed control, disrupt soil aggregates more extensively, potentially undermining the soil health benefits sought in CTF systems.

Compaction mitigation index

No-till drills significantly reduce soil compaction by minimizing disturbance, resulting in a lower Compaction Mitigation Index compared to disc harrows, which tend to compact soil layers due to aggressive tillage. The reduced soil compaction from no-till drills enhances root penetration and water infiltration, promoting healthier crop growth and improved soil structure.

Emergence uniformity score

No-till drills significantly improve emergence uniformity scores by minimizing soil disturbance and preserving seedbed moisture compared to disc harrows, which often create uneven seed placement and variable soil conditions. Studies show emergence uniformity can be enhanced by up to 30% using no-till drills over disc harrows, leading to more consistent crop stands and optimized yield potential.

Low-disturbance opener systems

No-till drills equipped with low-disturbance opener systems minimize soil disruption, preserving soil structure and moisture while enabling precise seed placement, which enhances crop emergence and reduces erosion risks. In contrast, disc harrows aggressively till the soil, increasing disturbance, disrupting soil aggregates, and potentially accelerating moisture loss and soil degradation.

Soil biological activity retention

No-till drills preserve soil biological activity by minimizing soil disturbance, maintaining microbial habitats and organic matter levels essential for nutrient cycling. In contrast, disc harrows disrupt soil structure, reducing microbial diversity and decreasing the overall soil health necessary for sustained crop productivity.

No-till drill vs Disc harrow for seedbed preparation Infographic

agridif.com

agridif.com