Primary processing of agricultural produce involves the initial steps such as cleaning, sorting, and grading to prepare raw materials for consumption or further processing. Secondary processing transforms these raw materials into finished or semi-finished products through methods like milling, drying, or packaging. Understanding the distinction enhances efficiency and value addition in the agri-food supply chain.

Table of Comparison

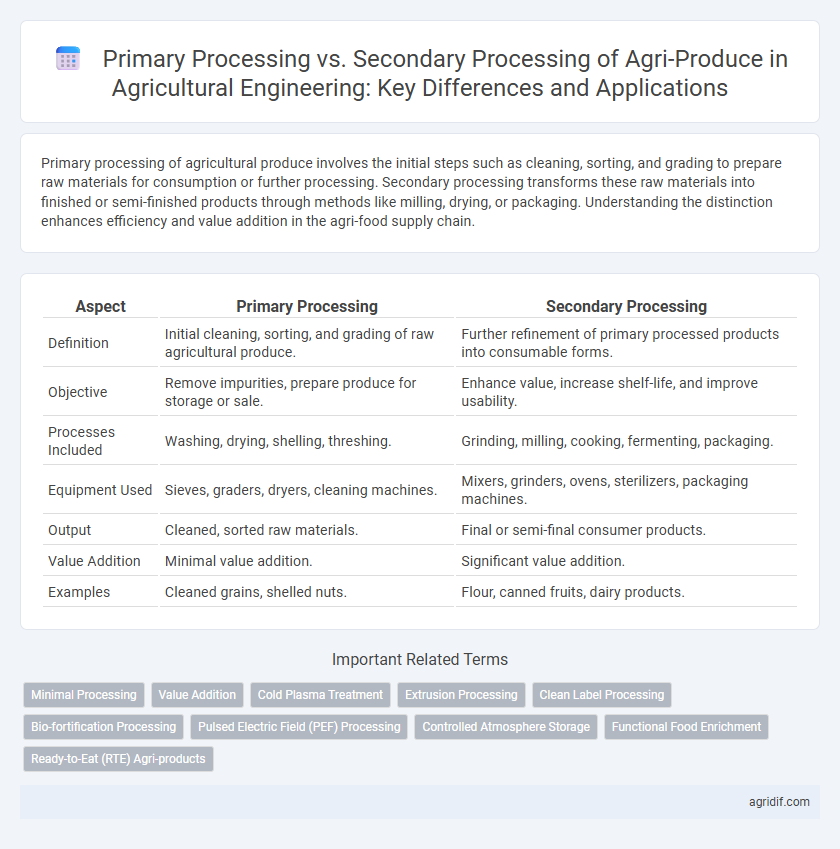

| Aspect | Primary Processing | Secondary Processing |

|---|---|---|

| Definition | Initial cleaning, sorting, and grading of raw agricultural produce. | Further refinement of primary processed products into consumable forms. |

| Objective | Remove impurities, prepare produce for storage or sale. | Enhance value, increase shelf-life, and improve usability. |

| Processes Included | Washing, drying, shelling, threshing. | Grinding, milling, cooking, fermenting, packaging. |

| Equipment Used | Sieves, graders, dryers, cleaning machines. | Mixers, grinders, ovens, sterilizers, packaging machines. |

| Output | Cleaned, sorted raw materials. | Final or semi-final consumer products. |

| Value Addition | Minimal value addition. | Significant value addition. |

| Examples | Cleaned grains, shelled nuts. | Flour, canned fruits, dairy products. |

Introduction to Primary and Secondary Processing in Agriculture

Primary processing in agriculture involves the initial transformation of harvested crops, such as cleaning, sorting, and drying, which prepares raw agricultural produce for storage and further use. Secondary processing refers to the conversion of primary-processed products into value-added goods like flour, oils, and packaged foods, enhancing shelf life and marketability. These stages are critical in reducing post-harvest losses and increasing the economic value of agricultural commodities.

Defining Primary Processing of Agri-Produce

Primary processing of agri-produce involves the initial steps that transform raw agricultural products into forms suitable for consumption or further processing. This stage includes cleaning, sorting, grading, and basic preservation techniques like drying or cooling to maintain quality and extend shelf life. It is essential for reducing post-harvest losses and preparing produce for secondary processing or direct market supply.

Key Techniques in Primary Processing

Primary processing of agri-produce involves key techniques such as cleaning, sorting, grading, and drying to enhance product quality and shelf life before further transformation. These methods remove impurities, separate products based on size and quality, and reduce moisture content, which are critical for maintaining freshness and preventing spoilage. Efficient primary processing directly impacts the effectiveness of secondary processing operations like milling, packaging, and value addition.

Secondary Processing: Concept and Scope

Secondary processing in agricultural engineering involves the transformation of primary agri-produce into value-added products through methods such as milling, refining, and packaging. This stage includes operations like drying, fermenting, and preserving, which enhance shelf life, quality, and marketability of food items. The scope extends to improving product safety, nutritional value, and consumer convenience, crucial for meeting industrial and retail standards.

Common Methods Used in Secondary Processing

Common methods used in secondary processing of agricultural produce include milling, fermentation, drying, and preservation techniques such as canning and freezing. These processes enhance shelf life, improve product quality, and add value by transforming raw materials into consumable goods like flour, yogurt, dried fruits, and canned vegetables. Efficient secondary processing reduces post-harvest losses and supports food security by enabling year-round availability of agricultural products.

Differences Between Primary and Secondary Processing

Primary processing of agricultural produce involves initial steps such as cleaning, sorting, grading, and drying to prepare raw materials for consumption or further processing. Secondary processing transforms primary processed goods into finished products through methods like milling, cooking, fermenting, and packaging, adding value and increasing shelf life. The key difference lies in primary processing focusing on preservation and quality maintenance, whereas secondary processing emphasizes value addition and product diversification.

Importance of Primary Processing in Value Addition

Primary processing in agricultural engineering involves basic cleaning, sorting, grading, and packaging of agri-produce, which significantly enhances product quality and marketability. It is essential for reducing post-harvest losses, maintaining nutritional value, and extending shelf life, directly contributing to value addition. Efficient primary processing lays the foundation for secondary processing by ensuring raw materials are standardized and suitable for further transformation into finished products.

Role of Secondary Processing in Product Diversification

Secondary processing in agricultural engineering involves transforming primary processed agri-produce into value-added products, enhancing product diversification and expanding market opportunities. This stage includes activities such as milling, fermenting, drying, and packaging, which improve shelf life, quality, and consumer appeal. By enabling the creation of diverse products like flour, oils, juices, and snacks, secondary processing plays a critical role in boosting farmers' incomes and contributing to rural economic development.

Technological Advances in Agricultural Processing

Primary processing in agricultural produce involves initial steps like cleaning, sorting, and grading using advanced technologies such as optical sorters and automated conveyors that enhance efficiency and reduce post-harvest losses. Secondary processing includes further value addition methods like milling, canning, and freezing, leveraging innovations like high-pressure processing and programmable logic controllers for consistent quality and extended shelf life. Integration of smart sensors and Internet of Things (IoT) devices in both processing stages optimizes resource use, monitors conditions, and ensures traceability throughout the supply chain.

Challenges and Future Trends in Agri-Produce Processing

Primary processing of agri-produce, involving cleaning, sorting, and grading, faces challenges such as contamination control, moisture management, and the need for energy-efficient machinery. Secondary processing, including milling, extracting, and packaging, struggles with maintaining nutritional quality, minimizing waste, and adapting to automation and digital technologies. Future trends focus on integrating IoT and AI for real-time quality monitoring, developing biodegradable packaging solutions, and enhancing energy-efficient, low-waste processing systems to address sustainability and food safety concerns.

Related Important Terms

Minimal Processing

Primary processing of agricultural produce involves initial steps such as cleaning, sorting, and grading to prepare raw materials for market, while secondary processing transforms these primary products into value-added goods like canned or frozen foods. Minimal processing techniques within primary processing aim to preserve freshness and nutritional quality by reducing handling and maintaining natural characteristics, enhancing shelf life and marketability without extensive alteration.

Value Addition

Primary processing of agricultural produce involves basic cleaning, sorting, and packaging that preserve raw materials, while secondary processing transforms these raw materials into value-added products through methods such as milling, fermentation, and preservation. Value addition in secondary processing enhances marketability, shelf life, and nutritional quality, significantly increasing farmers' income and reducing post-harvest losses.

Cold Plasma Treatment

Cold plasma treatment in primary processing effectively decontaminates fresh agricultural produce by inactivating pathogens and extending shelf life without chemical residues. In secondary processing, cold plasma enhances quality by modifying surface properties and improving texture, flavor, and preservation of agri-products such as grains and fruits.

Extrusion Processing

Primary processing in agricultural engineering involves basic operations such as cleaning, sorting, and grading of agri-produce to prepare raw materials for further use, while secondary processing refers to value addition techniques like extrusion processing that transform raw agricultural products into ready-to-consume or industrially usable forms. Extrusion processing uses high temperature, pressure, and shear forces to create textured, shelf-stable products from cereals, legumes, and oilseeds, significantly enhancing nutritional quality and product versatility.

Clean Label Processing

Primary processing in agricultural engineering involves initial treatments like cleaning, sorting, and drying of agri-produce to maintain freshness and remove impurities, crucial for achieving clean label standards by minimizing additives and preservatives. Secondary processing transforms these raw materials into value-added products through processes such as milling, fermentation, or packaging, emphasizing natural ingredients and transparent labeling to meet consumer demand for clean, minimally processed foods.

Bio-fortification Processing

Primary processing in agricultural engineering involves initial cleaning, sorting, and grading of bio-fortified crops to retain essential nutrients while preparing them for consumption. Secondary processing enhances the nutritional profile and shelf life through techniques like milling, drying, and fortification, ensuring bio-fortified produce meets dietary and market standards.

Pulsed Electric Field (PEF) Processing

Primary processing of agricultural produce involves initial cleaning, sorting, and basic preservation, while secondary processing integrates advanced techniques like Pulsed Electric Field (PEF) processing to enhance extraction efficiency, microbial inactivation, and shelf-life extension. PEF technology applies short bursts of high voltage to disrupt cell membranes, improving juice yield, preserving nutritional quality, and reducing thermal damage compared to conventional methods in both fruit and vegetable processing.

Controlled Atmosphere Storage

Controlled Atmosphere Storage plays a crucial role in primary processing by regulating oxygen, carbon dioxide, and humidity to slow down respiration and extend the shelf life of fresh agricultural produce. In contrast, secondary processing involves transforming raw materials into value-added products, where controlled atmosphere conditions are less critical compared to precision storage requirements in primary postharvest handling.

Functional Food Enrichment

Primary processing in agricultural engineering involves basic cleaning, sorting, and milling of agri-produce to retain essential nutrients and bioactive compounds critical for Functional Food Enrichment. Secondary processing focuses on advanced techniques like fermentation, fortification, and bioconversion that enhance the functional properties and bioavailability of health-promoting components in food products.

Ready-to-Eat (RTE) Agri-products

Primary processing involves initial steps like cleaning, sorting, and packaging raw agricultural produce to maintain freshness and quality, while secondary processing transforms these raw materials into Ready-to-Eat (RTE) agri-products through cooking, preserving, or freezing techniques that enhance shelf-life and convenience. Emphasizing hygiene and technology integration in secondary processing ensures the safety standards and nutritional value crucial for consumer-ready RTE agri-products.

Primary processing vs Secondary processing for agri-produce Infographic

agridif.com

agridif.com