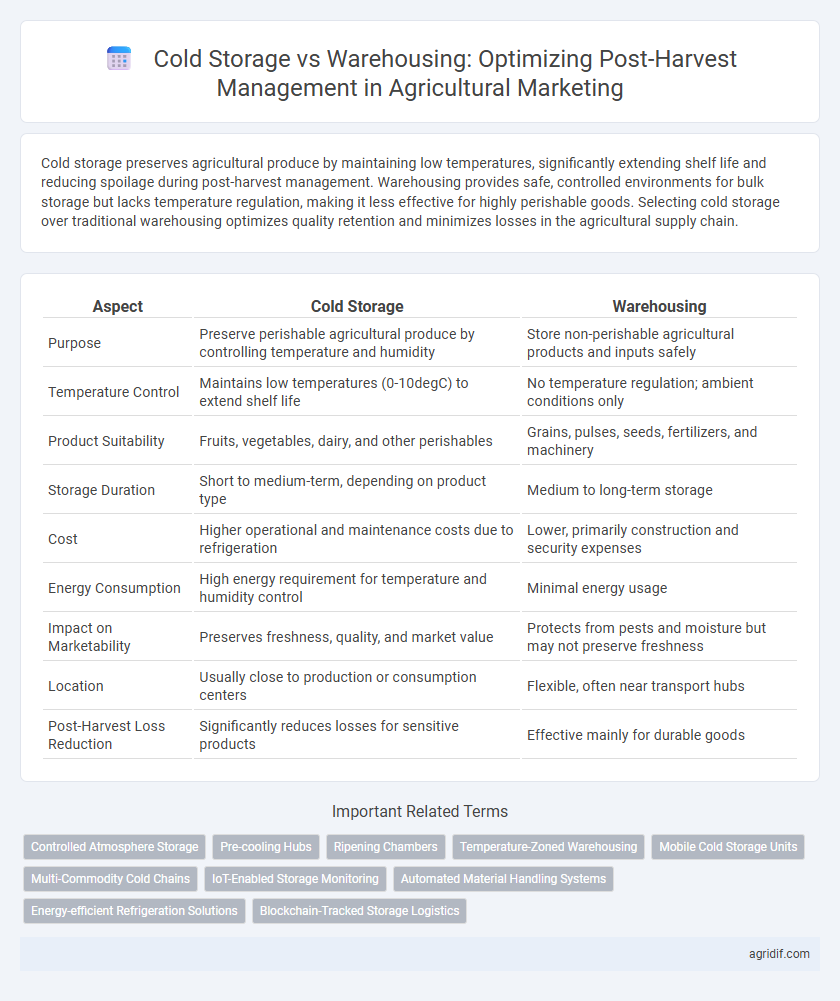

Cold storage preserves agricultural produce by maintaining low temperatures, significantly extending shelf life and reducing spoilage during post-harvest management. Warehousing provides safe, controlled environments for bulk storage but lacks temperature regulation, making it less effective for highly perishable goods. Selecting cold storage over traditional warehousing optimizes quality retention and minimizes losses in the agricultural supply chain.

Table of Comparison

| Aspect | Cold Storage | Warehousing |

|---|---|---|

| Purpose | Preserve perishable agricultural produce by controlling temperature and humidity | Store non-perishable agricultural products and inputs safely |

| Temperature Control | Maintains low temperatures (0-10degC) to extend shelf life | No temperature regulation; ambient conditions only |

| Product Suitability | Fruits, vegetables, dairy, and other perishables | Grains, pulses, seeds, fertilizers, and machinery |

| Storage Duration | Short to medium-term, depending on product type | Medium to long-term storage |

| Cost | Higher operational and maintenance costs due to refrigeration | Lower, primarily construction and security expenses |

| Energy Consumption | High energy requirement for temperature and humidity control | Minimal energy usage |

| Impact on Marketability | Preserves freshness, quality, and market value | Protects from pests and moisture but may not preserve freshness |

| Location | Usually close to production or consumption centers | Flexible, often near transport hubs |

| Post-Harvest Loss Reduction | Significantly reduces losses for sensitive products | Effective mainly for durable goods |

Introduction to Post-Harvest Management

Post-harvest management involves crucial steps to minimize loss and maintain quality of agricultural produce. Cold storage uses controlled low temperatures to slow down respiration and microbial growth, extending shelf life of perishable fruits and vegetables. Warehousing provides bulk storage under ambient or regulated conditions for grains and durable crops, facilitating inventory management and supply chain efficiency.

Defining Cold Storage and Warehousing

Cold storage refers to temperature-controlled facilities designed to preserve perishable agricultural products by slowing down metabolic processes and microbial growth, thereby extending shelf life. Warehousing encompasses general storage facilities used for a wide range of agricultural commodities, focusing primarily on protection against environmental factors like moisture, pests, and physical damage without temperature regulation. Post-harvest management benefits from cold storage for fruits, vegetables, dairy, and meat products, while warehousing suits grains, legumes, and other non-perishables requiring dry storage conditions.

Importance of Temperature Control in Agricultural Storage

Temperature control in agricultural storage is crucial for maintaining crop quality and extending shelf life by slowing down respiration and microbial growth. Cold storage units provide precise temperature regulation, reducing spoilage and preserving nutritional value, whereas traditional warehousing often lacks adequate climate control, leading to higher post-harvest losses. Effective temperature management directly impacts market value and food security by minimizing waste and ensuring fresh produce availability.

Comparative Advantages of Cold Storage

Cold storage offers superior temperature and humidity control compared to traditional warehousing, significantly reducing post-harvest losses in perishable agricultural commodities like fruits and vegetables. It extends shelf life by slowing down respiration and microbial activity, ensuring produce remains fresh during transportation and distribution. This precise environmental regulation enhances marketability and reduces economic risks for farmers and distributors in the agricultural supply chain.

Key Functions of Traditional Warehousing

Traditional warehousing in agricultural marketing primarily serves as a storage facility that safeguards harvested crops from physical damage, pests, and theft, maintaining the quality and quantity of produce until market distribution. It provides essential functions such as inventory management, consolidation of produce from multiple farmers, and facilitating bulk sales, which enhance market efficiency and price stabilization. Unlike cold storage, traditional warehouses do not control temperature or humidity, making them suitable for non-perishable commodities but less effective for highly perishable agricultural products requiring strict climate regulation.

Impact on Shelf Life and Product Quality

Cold storage significantly extends the shelf life of perishable agricultural products by maintaining optimal low temperatures and humidity levels, effectively reducing microbial growth and enzymatic activity. Warehousing, while essential for bulk storage and inventory management, lacks the temperature-controlled environment needed to preserve product freshness and quality over extended periods. Efficient post-harvest management prioritizes cold storage for maintaining product quality and minimizing spoilage, thereby enhancing market value and reducing losses.

Cost Analysis: Cold Storage vs. Warehousing

Cold storage facilities require higher initial investment and operational costs due to refrigeration equipment and energy consumption compared to traditional warehousing. While warehousing offers lower upfront expenses, it lacks temperature control that can lead to significant post-harvest losses, impacting overall cost efficiency. Evaluating long-term cost savings from reduced spoilage in cold storage versus the cheaper storage fees in warehousing is critical for effective post-harvest management decisions.

Suitability for Different Crop Types

Cold storage is ideal for perishable crops like fruits, vegetables, and dairy products that require temperature-controlled environments to maintain freshness and extend shelf life. Warehousing suits non-perishable commodities such as grains, pulses, and certain spices that do not need refrigeration but benefit from protection against moisture, pests, and contamination. Selecting the appropriate post-harvest storage depends on the crop's sensitivity to temperature and humidity, optimizing quality preservation and market value.

Role in Reducing Post-Harvest Losses

Cold storage plays a critical role in reducing post-harvest losses by maintaining optimal temperature and humidity levels, thereby extending the shelf life of perishable agricultural products. In contrast, conventional warehousing primarily provides protection against physical damage and theft but lacks the environmental controls necessary to prevent spoilage of fresh produce. Integrating cold storage facilities into agricultural supply chains significantly minimizes microbial growth and physiological degradation, enhancing food security and market value.

Future Trends in Post-Harvest Storage Solutions

Emerging post-harvest storage solutions increasingly prioritize integrating cold storage technology with smart warehousing systems that utilize IoT sensors and AI-driven climate control to optimize temperature and humidity levels for perishable agricultural products. Advancements in energy-efficient refrigeration and renewable energy integration aim to reduce the carbon footprint of cold storage facilities while extending shelf life and minimizing post-harvest losses. Future trends highlight modular, scalable storage units equipped with real-time monitoring and predictive analytics to enhance supply chain transparency and responsiveness in agricultural marketing.

Related Important Terms

Controlled Atmosphere Storage

Controlled Atmosphere Storage (CAS) in cold storage optimizes post-harvest management by precisely regulating oxygen, carbon dioxide, and humidity levels to significantly extend the shelf life of perishable agricultural products compared to traditional warehousing. This technology minimizes respiration rates and delays ripening, reducing spoilage and maintaining quality during long-term storage, which is critical for high-value fruits and vegetables in the agricultural supply chain.

Pre-cooling Hubs

Pre-cooling hubs in cold storage systems significantly extend the shelf life of perishable agricultural produce by rapidly reducing field heat, which minimizes spoilage and maintains quality during transport and storage. Unlike traditional warehousing, cold storage with pre-cooling hubs offers precise temperature and humidity control, crucial for preserving freshness and reducing post-harvest losses in fruits, vegetables, and flowers.

Ripening Chambers

Ripening chambers provide controlled temperature, humidity, and ethylene levels to uniformly mature fruits after harvest, ensuring optimal quality and market readiness. Unlike traditional warehousing that primarily offers storage space, cold storage combined with ripening chambers extends shelf life and enhances post-harvest value by managing the delicate ripening process effectively.

Temperature-Zoned Warehousing

Temperature-zoned warehousing in agricultural marketing offers precise climate control across different sections, ensuring optimal storage conditions tailored to diverse crop types and reducing post-harvest losses. Unlike standard cold storage, this advanced solution enhances product longevity and quality by simultaneously maintaining varying temperature and humidity levels for fruits, vegetables, and grains within a single facility.

Mobile Cold Storage Units

Mobile cold storage units enhance post-harvest management by providing flexible, temperature-controlled environments that reduce spoilage and maintain crop quality compared to traditional warehousing. These units empower farmers with on-site preservation, extending shelf life and facilitating timely market access in agricultural marketing.

Multi-Commodity Cold Chains

Multi-commodity cold chains enhance post-harvest management by maintaining optimal temperature and humidity, reducing spoilage for perishable agricultural commodities compared to traditional warehousing. Cold storage facilities equipped with advanced refrigeration technology extend shelf life, preserve quality, and ensure efficient supply chain logistics across diverse agricultural products.

IoT-Enabled Storage Monitoring

IoT-enabled storage monitoring enhances cold storage by providing real-time temperature and humidity control crucial for preserving perishable agricultural products, reducing spoilage and extending shelf life. In contrast, traditional warehousing lacks precise environmental controls, leading to higher risks of quality degradation during post-harvest storage.

Automated Material Handling Systems

Automated Material Handling Systems in cold storage facilities optimize temperature-controlled environments, reducing post-harvest spoilage and extending shelf life for perishable agricultural products. In contrast, warehousing with automation emphasizes efficient space utilization and inventory management but lacks the precise climate control essential for maintaining crop freshness.

Energy-efficient Refrigeration Solutions

Energy-efficient refrigeration solutions in cold storage significantly reduce post-harvest losses by maintaining optimal temperature and humidity for perishable agricultural products, preserving quality and extending shelf life. Warehousing, while essential for bulk storage, lacks specialized climate control, making energy-efficient cold storage facilities critical for sustainable agricultural marketing and minimizing waste.

Blockchain-Tracked Storage Logistics

Cold storage enhances post-harvest quality preservation by maintaining optimal temperature and humidity levels, while blockchain-tracked storage logistics ensure transparent and tamper-proof data on storage conditions and inventory movements. Integrating blockchain technology with cold storage and warehousing optimizes supply chain traceability, reduces spoilage, and improves farmer and buyer trust in agricultural marketing.

Cold Storage vs Warehousing for post-harvest management Infographic

agridif.com

agridif.com