Grading involves classifying harvested commodities based on predefined quality standards such as size, weight, and appearance, ensuring uniformity for market acceptance. Sorting, on the other hand, separates produce according to specific attributes like ripeness or defects, enhancing overall product quality by removing unsuitable items. Understanding the distinction between grading and sorting is crucial for effective agricultural marketing strategies that meet consumer expectations and increase market value.

Table of Comparison

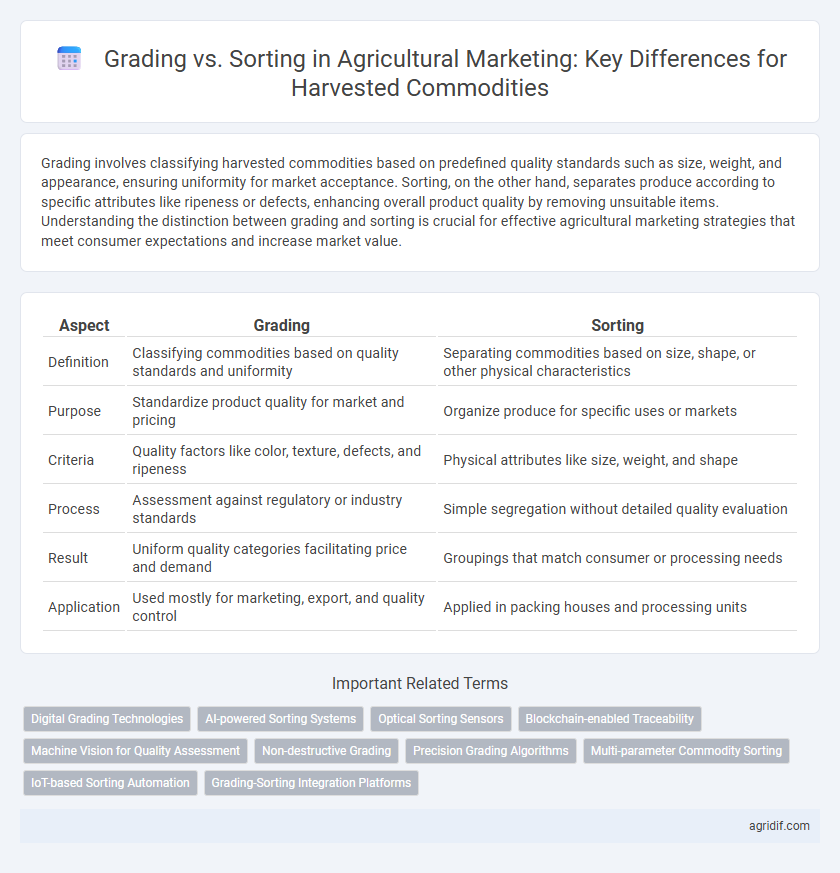

| Aspect | Grading | Sorting |

|---|---|---|

| Definition | Classifying commodities based on quality standards and uniformity | Separating commodities based on size, shape, or other physical characteristics |

| Purpose | Standardize product quality for market and pricing | Organize produce for specific uses or markets |

| Criteria | Quality factors like color, texture, defects, and ripeness | Physical attributes like size, weight, and shape |

| Process | Assessment against regulatory or industry standards | Simple segregation without detailed quality evaluation |

| Result | Uniform quality categories facilitating price and demand | Groupings that match consumer or processing needs |

| Application | Used mostly for marketing, export, and quality control | Applied in packing houses and processing units |

Introduction to Grading and Sorting in Agricultural Marketing

Grading in agricultural marketing involves categorizing harvested commodities based on predefined quality standards such as size, weight, color, and maturity to facilitate uniformity and meet market requirements. Sorting separates produce into different groups according to specific criteria like size or ripeness but does not assign a quality grade, primarily aiding in post-harvest handling and packaging efficiency. Both grading and sorting enhance marketability by ensuring consistent quality and streamlining supply chains for commodities like fruits, vegetables, and grains.

Defining Grading: Standards and Quality Parameters

Grading in agricultural marketing establishes standardized criteria to classify harvested commodities based on quality parameters such as size, color, texture, and defects. These standards ensure consistency, facilitate pricing, and enhance market transparency by categorizing produce into defined quality classes. Accurate grading supports supply chain efficiency by matching product quality with consumer expectations and regulatory requirements.

Understanding Sorting: Methods and Applications

Sorting in agricultural marketing involves classifying harvested commodities based on physical characteristics such as size, color, and shape, ensuring uniformity and meeting specific market requirements. Common sorting methods include manual inspection, mechanical sorting machines, and optical sorters that use cameras and sensors to detect defects and grade levels. Effective sorting enhances product quality, reduces post-harvest losses, and facilitates targeted marketing strategies aligned with consumer preferences.

Key Differences between Grading and Sorting

Grading classifies harvested commodities based on established quality standards such as size, weight, color, and defects, ensuring uniformity for market transactions. Sorting separates products into categories primarily focused on physical characteristics like size or ripeness but does not necessarily adhere to official quality benchmarks. Grading provides a standardized assessment facilitating price determination and market regulation, while sorting is a preparatory step aimed at organizing commodities for further processing or sale.

Importance of Grading for Market Value

Grading harvested commodities establishes standardized quality categories that directly influence market value by ensuring consistency and consumer trust. This process enables producers to fetch premium prices by accurately reflecting product attributes such as size, color, and maturity. Effective grading reduces post-harvest losses and enhances market efficiency by facilitating transparent trade and meeting regulatory requirements.

Role of Sorting in Supply Chain Efficiency

Sorting in agricultural supply chains enhances efficiency by categorizing harvested commodities based on size, weight, and quality attributes, facilitating better matching of products to market demands. This process reduces post-harvest losses, improves packaging accuracy, and streamlines logistics by enabling appropriate handling and storage conditions for different quality grades. Effective sorting ensures timely delivery of uniform products, boosting consumer satisfaction and optimizing overall supply chain performance.

Technologies Used in Grading and Sorting

Advanced grading and sorting technologies for harvested commodities incorporate optical sensors, near-infrared spectroscopy, and machine learning algorithms to assess quality attributes such as size, color, texture, and internal defects. These technologies enable rapid, accurate, and non-destructive evaluation, enhancing consistency and market value by categorizing produce according to strict industry standards. Automated sorting systems equipped with robotic arms and vision-based spectrometers optimize efficiency, reduce labor costs, and improve post-harvest handling in agricultural marketing.

Impact on Farmer Income and Consumer Satisfaction

Grading ensures harvested commodities meet specific quality standards, allowing farmers to command premium prices, while sorting categorizes products by size or appearance, enabling targeted market segments and reducing waste. Accurate grading enhances farmer income by promoting fair trade and building consumer trust in product consistency. Effective sorting improves consumer satisfaction by delivering uniform products, meeting expectations for appearance and usability.

Challenges in Implementing Grading and Sorting Systems

Implementing grading and sorting systems in agricultural marketing faces challenges such as inconsistent quality standards, limited access to advanced technologies, and insufficient training for farmers and laborers. Variability in produce characteristics and the high cost of infrastructure further complicate efficient classification. These obstacles hinder the establishment of reliable grading protocols crucial for market competitiveness and consumer trust.

Future Trends in Grading and Sorting Practices in Agriculture

Emerging technologies like AI-driven image analysis and hyperspectral sensing are revolutionizing grading and sorting of harvested commodities, enabling more precise quality assessment and defect detection. Automation and machine learning integration enhance real-time decision-making, reduce labor costs, and improve consistency in agricultural product classification. Future trends emphasize sustainability and traceability, incorporating blockchain for transparent grading data and supporting consumers' demand for high-quality, verified agricultural goods.

Related Important Terms

Digital Grading Technologies

Digital grading technologies enhance the precision and efficiency of agricultural commodity assessment by using advanced imaging and AI algorithms to classify produce based on quality standards, unlike traditional sorting which primarily separates items by size or weight. These technologies reduce human error, enable real-time data collection, and improve marketability by ensuring consistent quality grading that meets regulatory requirements.

AI-powered Sorting Systems

AI-powered sorting systems enhance agricultural marketing by providing precise differentiation of harvested commodities based on size, color, and quality attributes, increasing efficiency over traditional grading methods. These systems leverage machine learning algorithms and computer vision to automate sorting, ensuring uniformity and meeting market standards while reducing human error and labor costs.

Optical Sorting Sensors

Optical sorting sensors enhance precision in sorting harvested commodities by detecting color, size, shape, and surface defects, enabling rapid categorization without human error. Unlike traditional grading, which assigns quality based on universal standards, optical sorting allows for detailed, real-time differentiation and removal of substandard products, improving overall market value and reducing waste.

Blockchain-enabled Traceability

Grading categorizes harvested commodities based on standardized quality criteria such as size, color, and defect levels, enhancing market transparency and price consistency. Blockchain-enabled traceability records each grading event immutably, ensuring trust and verification in the supply chain by providing transparent, tamper-proof data on commodity quality and origin.

Machine Vision for Quality Assessment

Machine vision technology enhances grading by providing precise, consistent quality assessment of harvested commodities through real-time imaging and pattern recognition, distinguishing attributes such as size, color, and defects. Sorting leverages machine vision to categorize produce efficiently, optimizing market value by separating commodities based on quality standards, thereby reducing human error and increasing throughput.

Non-destructive Grading

Non-destructive grading techniques in agricultural marketing evaluate harvested commodities based on quality attributes like size, color, and firmness without damaging the produce, thus preserving marketable value and reducing waste. Unlike sorting, which separates commodities into predefined categories, grading assigns a quality score or grade, enabling precise pricing and improved supply chain efficiency.

Precision Grading Algorithms

Precision grading algorithms enhance the accuracy and consistency of agricultural commodity evaluation by analyzing multiple quality parameters such as size, color, and texture. Unlike traditional sorting methods that categorize produce based on basic visual cues, these algorithms leverage machine learning and spectral imaging to deliver objective, data-driven grading, improving marketability and reducing post-harvest losses.

Multi-parameter Commodity Sorting

Multi-parameter commodity sorting improves the quality and market value of harvested goods by categorizing products based on multiple attributes such as size, color, weight, and ripeness, enabling more precise and efficient market segmentation compared to traditional grading systems. Unlike single-parameter grading, multi-parameter sorting enhances uniformity and reduces post-harvest losses by ensuring commodities meet specific buyer requirements, ultimately optimizing supply chain management and consumer satisfaction.

IoT-based Sorting Automation

IoT-based sorting automation enhances precision by using real-time sensor data to classify harvested commodities based on size, color, and ripeness, optimizing market value and reducing manual errors compared to traditional grading, which primarily assesses quality standards post-harvest. This technology integrates Internet of Things devices and AI algorithms, enabling dynamic sorting that aligns with specific buyer requirements and improves supply chain efficiency.

Grading-Sorting Integration Platforms

Grading-Sorting Integration Platforms enhance agricultural marketing by combining quality assessment and size classification through automated systems, ensuring uniformity and meeting market standards for harvested commodities. These platforms increase efficiency in post-harvest handling by reducing manual labor, minimizing errors, and providing real-time data for better supply chain decisions.

Grading vs Sorting for harvested commodities Infographic

agridif.com

agridif.com