Emulsifiable concentrates offer superior solubility and ease of application in agrochemical formulations compared to wettable powders, which require thorough mixing to prevent sedimentation. Wettable powders provide better stability and longer shelf life but can cause nozzle clogging during spraying. Selecting between emulsifiable concentrates and wettable powders depends on factors such as crop type, environmental conditions, and application equipment efficiency.

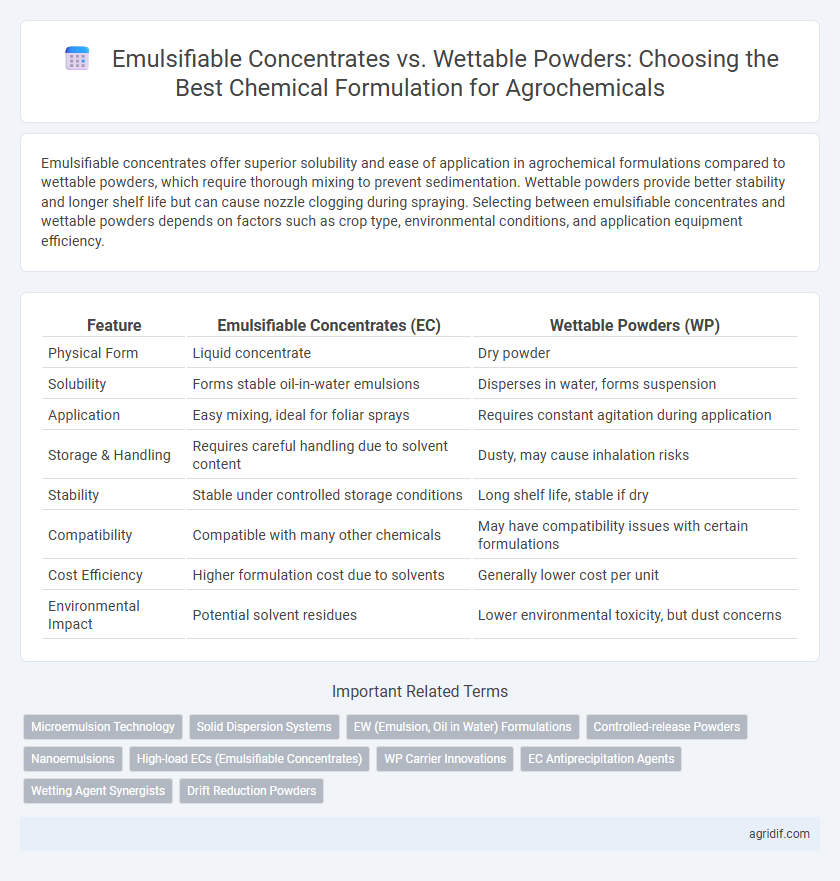

Table of Comparison

| Feature | Emulsifiable Concentrates (EC) | Wettable Powders (WP) |

|---|---|---|

| Physical Form | Liquid concentrate | Dry powder |

| Solubility | Forms stable oil-in-water emulsions | Disperses in water, forms suspension |

| Application | Easy mixing, ideal for foliar sprays | Requires constant agitation during application |

| Storage & Handling | Requires careful handling due to solvent content | Dusty, may cause inhalation risks |

| Stability | Stable under controlled storage conditions | Long shelf life, stable if dry |

| Compatibility | Compatible with many other chemicals | May have compatibility issues with certain formulations |

| Cost Efficiency | Higher formulation cost due to solvents | Generally lower cost per unit |

| Environmental Impact | Potential solvent residues | Lower environmental toxicity, but dust concerns |

Overview of Emulsifiable Concentrates and Wettable Powders

Emulsifiable concentrates (ECs) are liquid formulations composed of active ingredients dissolved in organic solvents combined with emulsifiers, allowing them to form stable oil-in-water emulsions when mixed with water. Wettable powders (WPs) consist of finely ground active ingredients blended with wetting and dispersing agents to create suspensions in water, facilitating ease of application and uniform distribution. Both ECs and WPs offer distinct advantages in agrochemical formulation, with ECs providing excellent coverage and penetration, while WPs are favored for their stability and reduced phytotoxicity.

Chemical Composition and Formulation Differences

Emulsifiable concentrates consist of active ingredients dissolved in organic solvents combined with emulsifiers to create stable oil-in-water emulsions upon dilution, enabling effective foliar application and rapid penetration. Wettable powders are finely ground solid formulations containing active ingredients mixed with wetting and dispersing agents, designed to be suspended in water rather than dissolved, ensuring uniform distribution and adhesion on plant surfaces. The chemical composition of emulsifiable concentrates favors lipophilic compounds, while wettable powders accommodate water-insoluble solids, resulting in distinct formulation stability, application methods, and environmental interactions.

Methods of Application in Agriculture

Emulsifiable concentrates (ECs) offer uniform coverage and rapid absorption when applied as sprays, making them ideal for foliar treatments in agriculture. Wettable powders (WPs) require thorough agitation in water to create suspensions, providing longer residual activity and better adherence on plant surfaces, especially in dusty or dry conditions. Selection between ECs and WPs depends on target pest, crop type, and environmental factors influencing application efficacy.

Advantages of Emulsifiable Concentrates in Crop Protection

Emulsifiable concentrates (ECs) offer superior solubility and ease of application in crop protection compared to wettable powders, facilitating more uniform and effective pesticide distribution on plant surfaces. EC formulations enhance chemical stability and penetration, leading to improved pest control efficiency while minimizing residue issues. Their low dust generation and compatibility with various spray equipment reduce environmental contamination and operator exposure risks during agrochemical application.

Benefits of Wettable Powders for Farmers

Wettable powders offer farmers enhanced storage stability and reduced risk of container corrosion compared to emulsifiable concentrates. These powders provide easy dilution in water, ensuring uniform application and minimizing chemical runoff. Their solid form lowers transportation costs and reduces exposure risks during handling, making them a safer and more economical choice for crop protection.

Compatibility with Other Agrochemicals

Emulsifiable concentrates exhibit superior compatibility with a wide range of agrochemicals, enhancing formulation flexibility and application efficiency. Wettable powders often face challenges with solubility and suspension stability when mixed with other chemicals, potentially causing sedimentation or uneven application. Formulators favor emulsifiable concentrates for integrated spray programs due to their stable emulsions and broad-spectrum compatibility with herbicides, fungicides, and insecticides.

Environmental Impact and Safety Considerations

Emulsifiable concentrates (ECs) often contain organic solvents that pose higher risks of environmental contamination and toxicity to aquatic life compared to wettable powders (WPs), which are primarily dry formulations with lower solvent content. Wettable powders reduce inhalation hazards during handling and minimize solvent-related environmental concerns, making them a safer option for applicators and non-target organisms. Selecting between ECs and WPs requires careful assessment of formulation toxicity, potential for soil and water contamination, and user exposure to ensure sustainable agrochemical use.

Storage, Handling, and Shelf Life

Emulsifiable concentrates exhibit superior storage stability due to their liquid formulation, reducing the risk of caking and facilitating easier handling compared to wettable powders, which are prone to moisture absorption and clumping. Wettable powders require careful moisture-controlled storage environments to maintain shelf life, typically shorter than emulsifiable concentrates, which can last several years under optimal conditions. The density and dust generation of wettable powders pose additional handling challenges, whereas emulsifiable concentrates offer safer, spill-resistant properties enhancing overall storage and operational efficiency in agrochemical applications.

Cost-Effectiveness and Economic Factors

Emulsifiable concentrates (ECs) offer higher cost-effectiveness due to their concentrated formulation, reducing packaging and transportation expenses, while wettable powders (WPs) incur higher costs in handling and mixing but often provide longer shelf life and stability. Economic factors favor ECs for bulk applications requiring rapid action and ease of use, whereas WPs are preferred when lower solvent use and reduced phytotoxicity minimize overall crop damage risks. Balancing initial formulation expenses with application efficiency and environmental impact determines the optimal agrochemical choice.

Choosing the Right Formulation for Your Farm

Emulsifiable concentrates offer superior solubility and ease of mixing, ensuring uniform application of agrochemicals, which reduces the risk of clogged sprayers on farms. Wettable powders provide better stability and longer shelf life, making them ideal for environments with variable storage conditions and delivering effective pest control through better adherence to plant surfaces. Selecting the right formulation depends on factors such as crop type, pest targeted, environmental conditions, and application equipment efficiency to optimize agrochemical performance and crop yield.

Related Important Terms

Microemulsion Technology

Emulsifiable concentrates offer superior solubility and uniform application compared to wettable powders, enabling enhanced penetration and efficacy of agrochemicals. Microemulsion technology optimizes these formulations by improving herbicide stability, reducing particle size to nanometer levels, and ensuring consistent dispersion for targeted pest control.

Solid Dispersion Systems

Emulsifiable concentrates (ECs) provide superior solubility through liquid formulations that enhance uniform distribution, while wettable powders (WPs) rely on solid dispersion systems to improve active ingredient stability and ease of handling. Solid dispersion in WPs enhances bioavailability by increasing surface area and improving wetting properties, critical for effective agrochemical delivery compared to the liquid medium used in ECs.

EW (Emulsion, Oil in Water) Formulations

Emulsifiable concentrates (EC) and wettable powders (WP) differ significantly in agrochemical formulation, with ECs offering superior solubility and ease of application due to their oil-in-water emulsion format, which enhances active ingredient dispersion and absorption. Emulsion, oil in water (EW) formulations provide improved stability, reduced volatility, and better adherence on plant surfaces compared to WPs, making them more efficient for targeted pest control and minimizing environmental impact.

Controlled-release Powders

Emulsifiable concentrates offer high solubility and ease of application but may cause rapid chemical degradation, whereas wettable powders, especially controlled-release powders, provide enhanced stability and gradual active ingredient release, improving efficacy and reducing environmental impact. Controlled-release powders in agrochemical formulations optimize pest management by maintaining consistent bioavailability, minimizing leaching, and extending field longevity compared to emulsifiable concentrates.

Nanoemulsions

Emulsifiable concentrates (ECs) offer enhanced solubility and ease of application in agrochemical formulations, while wettable powders (WPs) provide stability and reduced phytotoxicity but may suffer from dispersion challenges. Nanoemulsions within EC formulations improve bioavailability and target delivery efficiency by reducing droplet size, thereby increasing the surface area and enhancing the active ingredient's penetration in pest management.

High-load ECs (Emulsifiable Concentrates)

High-load emulsifiable concentrates (ECs) offer superior solubility and ease of application compared to wettable powders (WPs), enabling higher active ingredient concentrations and improved absorption in agrochemical formulations. While WPs require rigorous agitation and can cause abrasive wear on equipment, high-load ECs form stable emulsions that enhance uniform dispersion and reduce phytotoxicity risks on treated crops.

WP Carrier Innovations

Wettable powders (WP) leverage advanced carrier innovations like improved clays and silica to enhance dispersibility and stability without relying on solvents, offering environmentally safer alternatives to emulsifiable concentrates (EC) which use oil-based carriers that increase solvent load and volatilization risks. WP carriers optimize particle size distribution and surface chemistry, significantly improving chemical bioavailability and reducing formulation breakdown, making them ideal for sustainable agrochemical delivery systems.

EC Antiprecipitation Agents

Emulsifiable concentrates (EC) benefit from antiprecipitation agents that enhance stability by preventing phase separation and sedimentation, ensuring uniform application and consistent efficacy. Wettable powders (WP) require different formulations of antiprecipitation agents to maintain dispersion and avoid caking, critical for preserving bioavailability and ease of mixing in agrochemical treatments.

Wetting Agent Synergists

Wettable powders excel in agrochemical formulations by incorporating wetting agent synergists that enhance particle dispersion and improve spray coverage on hydrophobic crop surfaces. These synergists reduce surface tension more effectively than emulsifiable concentrates, promoting uniform application and increased pesticidal efficacy.

Drift Reduction Powders

Drift Reduction Powders (DRPs) in wettable powders enhance spray adhesion and reduce off-target pesticide movement by increasing droplet size and minimizing fine particle dispersion. Emulsifiable concentrates, while effective for uniform coverage, generally lack the particulate properties needed for drift mitigation compared to DRP-formulated wettable powders.

Emulsifiable concentrates vs Wettable powders for chemical formulation Infographic

agridif.com

agridif.com