Tank mixing combines multiple agrochemicals in a single spray application, improving efficiency and reducing labor costs, but requires careful compatibility checks to prevent chemical reactions. Sequential spraying applies chemicals separately in a specific order, minimizing the risk of antagonism and ensuring optimal performance of each product. Choosing between tank mixing and sequential spraying depends on crop type, chemical properties, and application timing for effective pest and disease control.

Table of Comparison

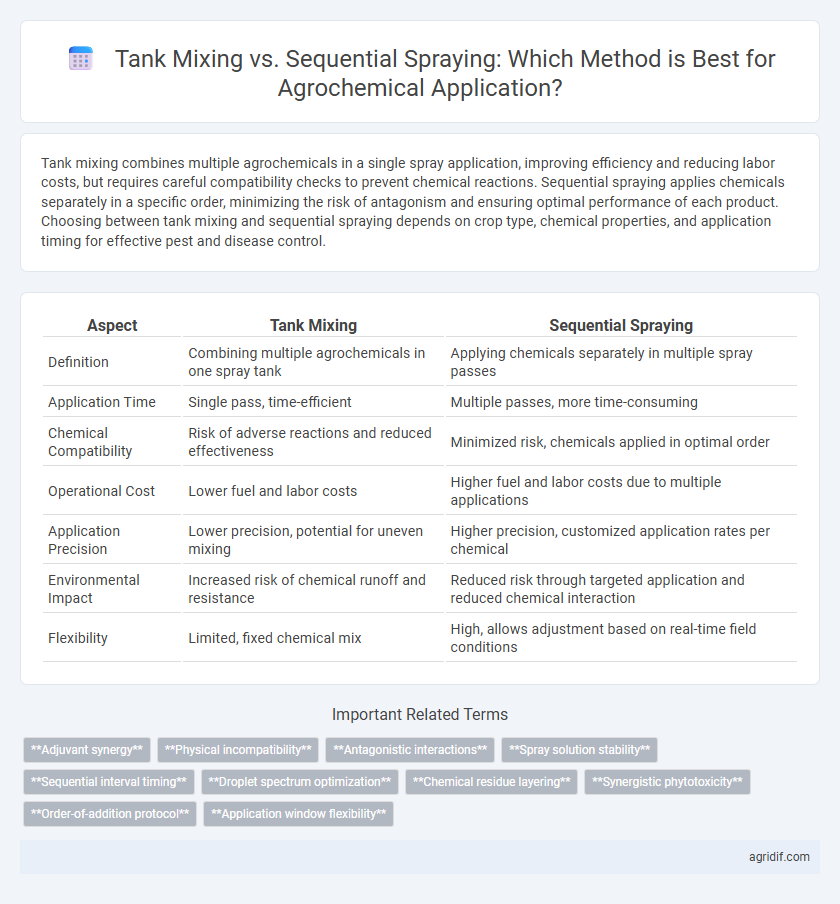

| Aspect | Tank Mixing | Sequential Spraying |

|---|---|---|

| Definition | Combining multiple agrochemicals in one spray tank | Applying chemicals separately in multiple spray passes |

| Application Time | Single pass, time-efficient | Multiple passes, more time-consuming |

| Chemical Compatibility | Risk of adverse reactions and reduced effectiveness | Minimized risk, chemicals applied in optimal order |

| Operational Cost | Lower fuel and labor costs | Higher fuel and labor costs due to multiple applications |

| Application Precision | Lower precision, potential for uneven mixing | Higher precision, customized application rates per chemical |

| Environmental Impact | Increased risk of chemical runoff and resistance | Reduced risk through targeted application and reduced chemical interaction |

| Flexibility | Limited, fixed chemical mix | High, allows adjustment based on real-time field conditions |

Understanding Tank Mixing in Agrochemical Application

Tank mixing in agrochemical application involves combining multiple pesticides, herbicides, or fertilizers in a single spray tank to enhance efficiency and reduce labor costs. Proper compatibility testing is essential to prevent chemical reactions that can reduce efficacy or cause crop damage. This method optimizes application by delivering a consistent mixture, but requires careful management to avoid antagonism or phytotoxicity.

Sequential Spraying: Definition and Process

Sequential spraying involves applying different agrochemicals separately, one after another, allowing for targeted action and minimizing chemical interactions. This method reduces the risk of tank mix incompatibility and enables precise timing for each chemical's optimal efficacy. Farmers use sequential spraying to enhance pest control, improve crop health, and optimize overall chemical use efficiency.

Key Benefits of Tank Mixing

Tank mixing in agrochemical application offers enhanced operational efficiency by combining multiple products into a single spray, reducing labor and time requirements. It ensures uniform distribution and compatibility of chemicals, improving pest control effectiveness and crop health. This method also minimizes environmental impact by decreasing the frequency of equipment cleaning and runoff risk compared to sequential spraying.

Advantages of Sequential Spraying Techniques

Sequential spraying techniques reduce the risk of chemical incompatibility by applying agrochemicals separately, ensuring optimal efficacy of each product. This method minimizes crop injury and environmental contamination by avoiding unwanted interactions between chemicals. Enhanced application flexibility allows tailored treatments based on crop stage and pest pressure, improving overall pest and disease management outcomes.

Compatibility Concerns in Tank Mixing

Tank mixing agrochemicals involves combining multiple pesticides or fertilizers in a single spray tank, which can lead to chemical incompatibility issues such as precipitation, reduced efficacy, or crop injury. Compatibility concerns include pH imbalance, solubility conflicts, and physical reactions between active ingredients or adjuvants, requiring pre-mixing tests like jar tests to identify potential problems. Sequential spraying eliminates these risks by applying chemicals separately, maintaining optimal performance and reducing the chance of adverse chemical interactions in the spray solution.

Efficacy Comparison: Tank Mixing vs Sequential Spraying

Tank mixing combines multiple agrochemicals in a single spray application, enhancing efficacy by ensuring uniform coverage and simultaneous pest or disease control, which can reduce application time and labor costs. Sequential spraying involves applying chemicals separately, allowing targeted treatment and reducing potential chemical interactions that can degrade efficacy, but may increase application time and operational costs. Studies show tank mixing is more efficient for broad-spectrum pest management, while sequential spraying offers better control in cases requiring specific timing or when chemical incompatibility is a concern.

Impact on Crop Safety and Phytotoxicity

Tank mixing agrochemicals allows simultaneous application of multiple products, reducing application time but increasing the risk of chemical incompatibility and phytotoxicity if mixtures are not properly tested. Sequential spraying, applying chemicals separately with appropriate intervals, minimizes adverse chemical interactions and enhances crop safety by allowing crops to recover between treatments. Research demonstrates that sequential applications often result in lower phytotoxicity incidents and improved overall crop health compared to tank-mixed applications.

Labour and Cost Implications of Both Methods

Tank mixing reduces labor requirements by combining multiple agrochemicals into a single application, which saves time and minimizes operational costs. Sequential spraying increases labor demands due to multiple application passes and extended machinery use, leading to higher fuel consumption and maintenance expenses. Choosing tank mixing optimizes cost efficiency and labor allocation, especially for large-scale farming operations.

Environmental Considerations in Application Methods

Tank mixing reduces the number of field passes, lowering fuel consumption and minimizing soil compaction, which benefits overall soil health and reduces greenhouse gas emissions. Sequential spraying, however, allows for tailored application of agrochemicals, decreasing the risk of chemical interactions that can lead to environmental contamination. Careful management of both methods is essential to prevent runoff and protect water quality in surrounding ecosystems.

Best Practices for Chemical Application in Agriculture

Tank mixing enables simultaneous application of multiple agrochemicals, enhancing efficiency and uniform coverage, but requires compatibility testing to avoid chemical antagonism. Sequential spraying reduces the risk of phytotoxicity by applying chemicals separately, allowing precise timing and dosage adjustments tailored to crop growth stages. Best practices emphasize thorough calibration, equipment cleaning between applications, and adherence to label instructions to ensure optimal efficacy and minimize environmental impact.

Related Important Terms

Adjuvant synergy

Tank mixing maximizes adjuvant synergy by allowing multiple agrochemicals to interact simultaneously, enhancing spray efficacy and reducing application time. Sequential spraying limits this synergy as separate chemical layers may not mix optimally, potentially decreasing overall pesticide performance and increasing drift risk.

Physical incompatibility

Physical incompatibility in tank mixing for agrochemical application often causes issues such as precipitation, phase separation, or poor sprayability, leading to reduced efficacy and potential equipment clogging. Sequential spraying minimizes these risks by applying chemicals separately, preserving their individual stability and ensuring optimal performance without adverse interactions.

Antagonistic interactions

Tank mixing in agrochemical applications can lead to antagonistic interactions where chemicals react negatively, reducing overall efficacy and potentially causing crop damage. Sequential spraying minimizes these risks by applying each chemical separately, preventing direct chemical interference and maintaining optimal performance of each agrochemical product.

Spray solution stability

Tank mixing can compromise spray solution stability due to chemical interactions that cause precipitates or reduced efficacy, whereas sequential spraying minimizes these risks by applying chemicals separately, preserving their individual stability and performance. Ensuring optimal spray solution stability is crucial for consistent agrochemical application efficacy and crop safety.

Sequential interval timing

Sequential spraying with carefully managed interval timing minimizes chemical interactions and enhances target pest control efficacy by allowing each agrochemical to act independently before the next application. This approach reduces the risk of antagonistic reactions common in tank mixing, improving overall crop protection and minimizing phytotoxicity.

Droplet spectrum optimization

Tank mixing enables more precise droplet spectrum optimization by combining multiple agrochemicals in a single spray solution, ensuring uniform droplet size distribution and improved coverage. Sequential spraying may lead to variable droplet spectra due to different nozzle settings and spray pressures, potentially reducing overall application efficiency and effectiveness.

Chemical residue layering

Tank mixing can reduce chemical residue layering by combining active ingredients in a single application, promoting uniform distribution and minimizing overlapping deposits. Sequential spraying tends to increase residue layering due to multiple passes, which can elevate the risk of phytotoxicity and affect crop safety.

Synergistic phytotoxicity

Tank mixing agrochemicals can increase the risk of synergistic phytotoxicity, where combined chemical interactions cause greater damage to crops than individual applications. Sequential spraying minimizes this risk by allowing time between applications, reducing chemical interaction and enhancing crop safety during pest and disease management.

Order-of-addition protocol

Order-of-addition protocol in agrochemical application critically influences tank mixing efficacy by dictating the sequence in which pesticides and fertilizers are combined to prevent chemical incompatibilities and ensure optimal active ingredient performance. Sequential spraying mitigates adverse reactions by applying each chemical separately, allowing for precise timing and reduced risk of antagonistic interactions that commonly occur in improper tank mix sequences.

Application window flexibility

Tank mixing allows simultaneous application of multiple agrochemicals, broadening the application window by reducing the time between treatments. Sequential spraying offers greater flexibility in timing each application separately, optimizing effectiveness based on specific crop growth stages and environmental conditions.

Tank mixing vs Sequential spraying for chemical application Infographic

agridif.com

agridif.com