Granular fertilizers provide a slow-release nutrient supply, improving soil structure and reducing nutrient loss through leaching, making them ideal for long-term nutrient application in agrochemicals. Liquid fertilizers offer rapid nutrient availability and uniform distribution, enhancing plant uptake efficiency and allowing precise application tailored to crop needs. Choosing between granular and liquid fertilizers depends on specific crop requirements, soil conditions, and desired nutrient delivery timing in agrochemical management.

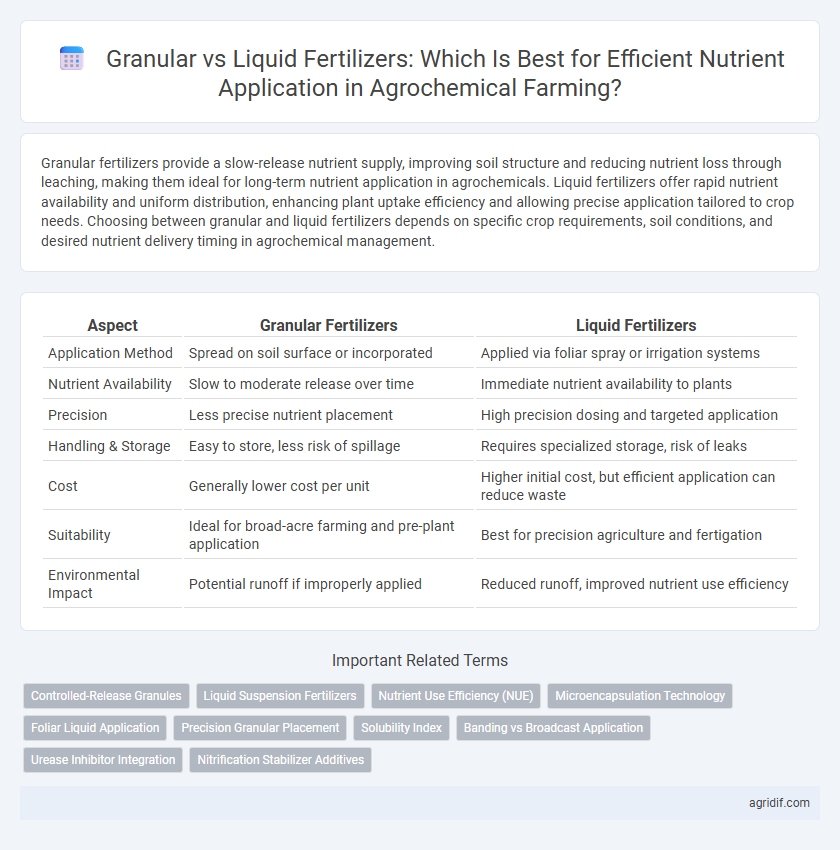

Table of Comparison

| Aspect | Granular Fertilizers | Liquid Fertilizers |

|---|---|---|

| Application Method | Spread on soil surface or incorporated | Applied via foliar spray or irrigation systems |

| Nutrient Availability | Slow to moderate release over time | Immediate nutrient availability to plants |

| Precision | Less precise nutrient placement | High precision dosing and targeted application |

| Handling & Storage | Easy to store, less risk of spillage | Requires specialized storage, risk of leaks |

| Cost | Generally lower cost per unit | Higher initial cost, but efficient application can reduce waste |

| Suitability | Ideal for broad-acre farming and pre-plant application | Best for precision agriculture and fertigation |

| Environmental Impact | Potential runoff if improperly applied | Reduced runoff, improved nutrient use efficiency |

Understanding Granular and Liquid Fertilizers: Key Differences

Granular fertilizers consist of solid particles that release nutrients slowly, providing long-lasting soil enrichment ideal for sustained crop growth. Liquid fertilizers offer rapid nutrient availability through easy absorption, enhancing immediate plant uptake and precise application in foliar feeding or fertigation. Understanding the application methods, nutrient release rates, and crop requirements is crucial for selecting between granular and liquid fertilizers to optimize nutrient efficiency and crop yield.

How Granular Fertilizers Work in Soil Nutrient Delivery

Granular fertilizers release nutrients slowly through soil moisture dissolution, allowing roots to absorb essential elements over time and enhancing nutrient use efficiency. Their solid form enables precise placement near plant roots, minimizing nutrient loss due to leaching or volatilization. Soil microbes further aid in breaking down granules, gradually converting nutrients into plant-available forms, supporting sustained crop growth.

Liquid Fertilizers: Fast-Acting Solutions for Crop Nutrition

Liquid fertilizers provide rapid nutrient availability for crops, enhancing uptake efficiency and promoting swift growth responses compared to granular fertilizers. Their easy application through foliar feeding or fertigation systems ensures uniform distribution and reduces nutrient losses due to volatilization or leaching. High solubility and precise nutrient formulations make liquid fertilizers ideal for correcting deficiencies quickly and supporting critical growth stages in crop production.

Comparing Application Methods: Granular vs. Liquid Fertilizers

Granular fertilizers are typically applied directly to the soil surface or incorporated into the soil, providing a slow and steady nutrient release that supports sustained crop growth. Liquid fertilizers offer rapid nutrient availability through foliar feeding or fertigation, allowing precise nutrient management and quick correction of deficiencies. Choosing between granular and liquid fertilizers depends on factors such as crop type, soil conditions, and timing of nutrient requirements.

Nutrient Availability and Uptake: Which Fertilizer Performs Better?

Granular fertilizers release nutrients slowly into the soil, providing steady nutrient availability, while liquid fertilizers offer immediate nutrient uptake due to their rapid solubility and absorption by plant roots. The efficacy of nutrient availability depends on soil moisture and temperature, with liquid fertilizers performing better in dry or nutrient-deficient soils where quick nutrient delivery is essential. In contrast, granular fertilizers are more effective for sustained nutrient release, supporting long-term crop growth and minimizing nutrient leaching.

Cost Analysis: Economics of Granular and Liquid Fertilizers

Granular fertilizers typically offer lower upfront costs and longer shelf life, making them more cost-effective for large-scale nutrient application over time. Liquid fertilizers, while often more expensive per unit, provide precise nutrient delivery and faster absorption, potentially reducing overall input requirements and labor costs. Evaluating the total cost of ownership, including application efficiency and crop response, is essential for optimizing fertilizer economics in agrochemical management.

Environmental Impact: Runoff and Leaching Considerations

Granular fertilizers generally result in lower nutrient runoff compared to liquid fertilizers due to their slower nutrient release and better soil retention, reducing the risk of water contamination. Liquid fertilizers, while offering rapid nutrient availability, pose a higher risk of nutrient leaching and surface runoff, especially during heavy rainfall or over-irrigation. Effective management practices such as controlled application timing and rates are essential to minimize the environmental impact of both fertilizer types on surrounding ecosystems.

Suitability for Different Crops and Growth Stages

Granular fertilizers offer precise nutrient release ideal for staple crops like wheat and maize, particularly effective during early growth stages requiring steady nutrient supply. Liquid fertilizers provide rapid nutrient absorption, suited for high-value crops such as vegetables and fruits, especially during critical growth phases like flowering and fruit set. Selecting fertilizer form based on crop type and growth stage optimizes nutrient uptake efficiency and enhances yield outcomes.

Storage, Handling, and Equipment Requirements

Granular fertilizers offer easier storage and longer shelf life due to their solid form, requiring minimal special handling and standard spreaders for application. Liquid fertilizers necessitate specialized storage tanks resistant to corrosion and precise handling equipment like pump systems and spray nozzles to ensure uniform nutrient distribution. Equipment choice significantly impacts application efficiency and nutrient availability, influencing crop yield and operational costs in agrochemical practices.

Choosing the Right Fertilizer: Making Data-Driven Decisions

Granular fertilizers provide controlled nutrient release and ease of storage, ideal for crops requiring steady nutrient supply, while liquid fertilizers offer rapid nutrient availability and precise application suited for foliar feeding and rapid crop response. Data-driven decisions hinge on soil nutrient profiles, crop growth stages, and environmental conditions to optimize nutrient use efficiency and crop yield. Selecting the appropriate fertilizer type involves integrating field sensor data, crop nutrient demand models, and cost-benefit analyses to ensure sustainable and effective nutrient management.

Related Important Terms

Controlled-Release Granules

Controlled-release granular fertilizers provide precise nutrient delivery through polymer coatings that regulate nutrient release rates, enhancing efficiency and reducing leaching losses compared to conventional liquid fertilizers. These granules improve crop uptake by synchronizing nutrient availability with plant growth stages, optimizing nutrient use efficiency and minimizing environmental impact.

Liquid Suspension Fertilizers

Liquid suspension fertilizers offer superior nutrient uniformity and faster plant uptake compared to granular fertilizers, enhancing crop growth efficiency. Their ability to deliver precise nutrient formulations and reduce soil nutrient fixation makes them ideal for targeted agrochemical applications.

Nutrient Use Efficiency (NUE)

Granular fertilizers provide slow nutrient release, enhancing Nutrient Use Efficiency (NUE) by reducing leaching and volatilization losses in soil. Liquid fertilizers offer precise nutrient delivery with rapid uptake, improving NUE in targeted crop growth stages but require careful management to prevent runoff and nutrient imbalance.

Microencapsulation Technology

Microencapsulation technology enhances nutrient efficiency by controlling the release rate in both granular and liquid fertilizers, improving nutrient uptake and reducing environmental impact. Granular fertilizers with microencapsulation provide targeted, slow-release nutrient delivery, while liquid fertilizers enable uniform application and rapid availability of microencapsulated nutrients.

Foliar Liquid Application

Foliar liquid fertilizers enable rapid nutrient absorption through plant leaves, enhancing efficiency and immediate nutrient availability compared to granular fertilizers that rely on soil microbial activity for nutrient release. This targeted foliar application reduces nutrient loss through leaching and volatilization, optimizing crop nutrient uptake and improving overall yield quality.

Precision Granular Placement

Precision granular placement in granular fertilizers enhances nutrient availability by delivering concentrated nutrients directly to the root zone, reducing losses and improving uptake efficiency compared to liquid fertilizers. This targeted approach supports uniform crop growth and minimizes environmental impact by limiting nutrient runoff and volatilization.

Solubility Index

Granular fertilizers typically exhibit lower solubility indices compared to liquid fertilizers, resulting in slower nutrient release and prolonged availability in the soil. Liquid fertilizers possess higher solubility indexes, allowing immediate nutrient absorption and rapid uptake by crops, enhancing efficiency in precise nutrient management.

Banding vs Broadcast Application

Granular fertilizers applied through banding deliver nutrients directly to the root zone, enhancing nutrient use efficiency and reducing volatilization losses compared to broadcast application, which spreads nutrients across the soil surface and can result in uneven distribution and increased runoff risk. Liquid fertilizers, when banded, allow precise placement and rapid nutrient uptake, but broadcast application may lead to faster nutrient fixation in the soil and lower overall availability to crops.

Urease Inhibitor Integration

Granular fertilizers with urease inhibitor integration slow the conversion of urea into ammonia, reducing nitrogen loss through volatilization and enhancing nutrient use efficiency in soil applications. Liquid fertilizers, while offering rapid nutrient availability, often require precise dosage management to prevent nitrogen leaching, making urease inhibitor usage critical for optimizing nutrient uptake and minimizing environmental impact.

Nitrification Stabilizer Additives

Granular fertilizers with nitrification stabilizer additives provide slow-release nitrogen, reducing leaching and enhancing nutrient use efficiency in crop production. Liquid fertilizers allow precise application and rapid nutrient availability, but incorporating nitrification inhibitors in granular forms optimizes nitrogen retention and minimizes environmental impact.

Granular Fertilizers vs Liquid Fertilizers for Nutrient Application Infographic

agridif.com

agridif.com