All-in All-out (AIAO) systems enhance biosecurity and reduce disease transmission by moving groups of swine through production stages simultaneously and thoroughly cleaning facilities between batches. Continuous Flow systems allow for multiple groups of pigs at different stages to occupy the same space, but increase the risk of pathogen spread and complicate herd health management. Implementing AIAO improves overall swine production efficiency, growth rates, and minimizes antibiotic usage compared to Continuous Flow management.

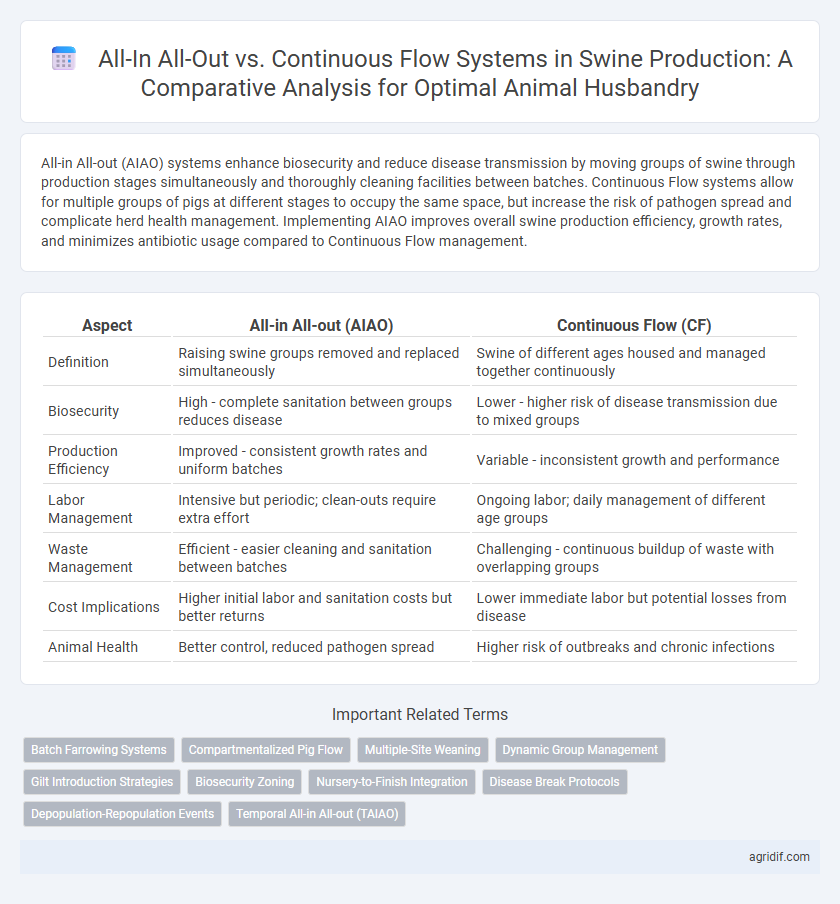

Table of Comparison

| Aspect | All-in All-out (AIAO) | Continuous Flow (CF) |

|---|---|---|

| Definition | Raising swine groups removed and replaced simultaneously | Swine of different ages housed and managed together continuously |

| Biosecurity | High - complete sanitation between groups reduces disease | Lower - higher risk of disease transmission due to mixed groups |

| Production Efficiency | Improved - consistent growth rates and uniform batches | Variable - inconsistent growth and performance |

| Labor Management | Intensive but periodic; clean-outs require extra effort | Ongoing labor; daily management of different age groups |

| Waste Management | Efficient - easier cleaning and sanitation between batches | Challenging - continuous buildup of waste with overlapping groups |

| Cost Implications | Higher initial labor and sanitation costs but better returns | Lower immediate labor but potential losses from disease |

| Animal Health | Better control, reduced pathogen spread | Higher risk of outbreaks and chronic infections |

Introduction to Swine Production Systems

All-in all-out swine production systems improve biosecurity by moving groups of pigs through production stages together, reducing disease transmission risks. Continuous flow systems allow the constant introduction of new pigs but increase the chances of pathogen spread due to mixed-age groups sharing facilities. Choosing between these systems depends on farm size, management resources, and disease control priorities in swine production.

What is All-in All-out (AIAO) Management?

All-in All-out (AIAO) management is a swine production strategy where groups of pigs are moved through production stages together, allowing entire barns to be cleaned and disinfected between groups. This method reduces disease transmission by minimizing contact between different age groups and helps maintain biosecurity. AIAO enhances overall herd health and improves growth performance compared to continuous flow systems.

Understanding Continuous Flow Operations

Continuous flow operations in swine production involve raising multiple groups of pigs at various stages of growth simultaneously within the same facility. This method can increase production throughput and facility utilization but often elevates the risk of disease transmission due to overlapping age groups and shared environments. Effective biosecurity protocols and targeted health management strategies are essential to mitigate health challenges associated with continuous flow systems.

Key Differences Between AIAO and Continuous Flow

All-in All-out (AIAO) production involves moving entire groups of swine through production stages simultaneously, promoting stringent biosecurity by allowing thorough cleaning between batches and minimizing disease transmission. Continuous Flow systems permit overlapping groups at different production phases, increasing risk of pathogen spread due to constant animal movement and mixed-age populations. Key differences include AIAO's batch processing which improves health management and reduces medication costs, whereas Continuous Flow offers production flexibility but demands enhanced disease control measures.

Impact on Swine Health and Biosecurity

All-in All-out (AIAO) swine production significantly reduces disease transmission by allowing thorough cleaning and disinfection between groups, thereby enhancing biosecurity and overall herd health. Continuous Flow systems increase the risk of pathogen persistence due to overlapping age groups and constant animal movement, leading to higher incidence of respiratory and enteric diseases. Implementing AIAO protocols improves immune response consistency and lowers antimicrobial usage by minimizing cross-contamination and biofilm buildup within facilities.

Productivity and Performance Comparison

All-in All-out (AIAO) swine production systems enhance productivity by reducing disease transmission and improving biosecurity, leading to better growth rates and feed efficiency compared to Continuous Flow systems. Continuous Flow allows mixing of different age groups, increasing the risk of disease spread and resulting in inconsistent performance metrics such as average daily gain (ADG) and feed conversion ratio (FCR). Studies show that AIAO practices significantly improve herd health and uniformity, translating into higher overall production efficiency and economic returns.

Economic Considerations in System Selection

All-in All-out (AIAO) systems in swine production reduce disease transmission and mortality rates, enhancing economic efficiency through improved growth performance and lower medical costs. Continuous flow systems may offer more flexibility and steady production cycles but often incur higher expenses due to increased health risks and variable feed conversion ratios. Economic considerations favor AIAO for maximizing profitability by optimizing biosecurity and minimizing production losses.

Labor and Facility Requirements

All-in All-out (AIAO) swine production systems optimize labor efficiency by synchronizing group movements, reducing cleaning and downtime between batches, and minimizing disease transmission risks. Continuous Flow (CF) systems require constant labor attention for managing multiple age groups simultaneously, increasing complexity in sanitation and animal flow logistics. Facility design under AIAO demands segmented housing with thorough cleaning protocols, while CF favors integrated facilities but at the cost of greater labor intensity and biosecurity challenges.

Environmental and Waste Management Implications

All-in All-out (AIAO) swine production minimizes environmental impact by reducing pathogen spread and enabling thorough cleaning between batches, which improves waste management efficiency and lowers ammonia emissions. Continuous Flow systems increase the risk of disease transmission, leading to higher antibiotic use and more unstable manure nutrient profiles that challenge effective treatment and disposal. Implementing AIAO supports compliance with environmental regulations through better control of pollutants and enhanced biosecurity measures.

Making the Right Choice for Your Swine Operation

Choosing between All-in All-out and Continuous Flow methods significantly impacts biosecurity and growth performance in swine production. All-in All-out systems enhance disease control by allowing thorough cleaning between groups, while Continuous Flow may increase disease risk due to constant animal mixing. Evaluating factors such as farm size, labor capacity, and animal health goals helps determine the optimal approach for maximizing productivity and minimizing risks.

Related Important Terms

Batch Farrowing Systems

Batch farrowing systems in swine production employ an all-in all-out approach, which improves biosecurity and reduces disease transmission by synchronizing piglet groups for simultaneous movement and cleaning. Continuous flow systems, in contrast, allow mixing of different age groups, increasing the risk of pathogen spread and complicating health management.

Compartmentalized Pig Flow

Compartmentalized pig flow in all-in all-out (AIAO) swine production enhances biosecurity by minimizing disease transmission through strict separation of pig groups by age and production stage. This contrasts with continuous flow systems, where overlapping groups increase the risk of pathogen spread and complicate health management.

Multiple-Site Weaning

Multiple-site weaning in swine production enhances biosecurity and disease control by implementing the all-in all-out system, which segregates piglets by age and batch, reducing pathogen transmission across groups. Continuous flow production increases the risk of disease spread due to overlapping age groups and shared facilities, making multiple-site weaning combined with all-in all-out management a preferred method for maximizing health and performance outcomes.

Dynamic Group Management

Dynamic Group Management in swine production enhances All-in All-out systems by segregating pigs based on age and health status, minimizing disease transmission and optimizing growth performance. Continuous Flow systems lack this segregation, increasing pathogen exposure and compromising herd health efficiency.

Gilt Introduction Strategies

All-in all-out swine production minimizes disease transmission by systematically moving groups of pigs through production phases, enhancing gilt integration through synchronized acclimatization and batching strategies. In contrast, continuous flow systems increase biosecurity risks and complicate gilt introduction, often requiring rigorous quarantine and acclimation protocols to maintain herd health.

Biosecurity Zoning

All-in All-out (AIAO) swine production enhances biosecurity zoning by strictly separating groups of pigs by age and production stage, reducing pathogen transmission between batches. Continuous flow systems hinder effective biosecurity zoning due to overlapping age groups and continuous introduction of new animals, increasing the risk of disease spread in swine facilities.

Nursery-to-Finish Integration

All-in All-out (AIAO) production systems enhance biosecurity and reduce disease transmission by maintaining strict batch segregation, which is critical in nursery-to-finish integration for swine. Continuous Flow systems, while enabling constant operation, increase pathogen risk due to overlapping pig age groups, compromising overall herd health and productivity.

Disease Break Protocols

All-in All-out (AIAO) swine production strictly separates groups by age, allowing complete cleaning and disinfection between batches to break disease cycles effectively. Continuous Flow systems mix different age groups, increasing pathogen persistence and making disease break protocols less effective due to constant exposure.

Depopulation-Repopulation Events

All-in All-out swine production optimizes biosecurity by allowing complete depopulation followed by thorough sanitation before repopulation, significantly reducing disease transmission during repopulation events. Continuous flow systems increase the risk of pathogen persistence due to overlapping groups, complicating effective depopulation-repopulation cycles and potentially leading to chronic health issues in swine populations.

Temporal All-in All-out (TAIAO)

Temporal All-in All-out (TAIAO) swine production schedules pigs to enter and exit facilities within specific time frames, minimizing pathogen transmission by ensuring that all animals share the same production phase simultaneously. This method enhances biosecurity and improves overall herd health compared to Continuous Flow systems, which allow pigs of varying ages to mix, increasing disease risk and complicating management.

All-in All-out vs Continuous Flow for Swine Production Infographic

agridif.com

agridif.com