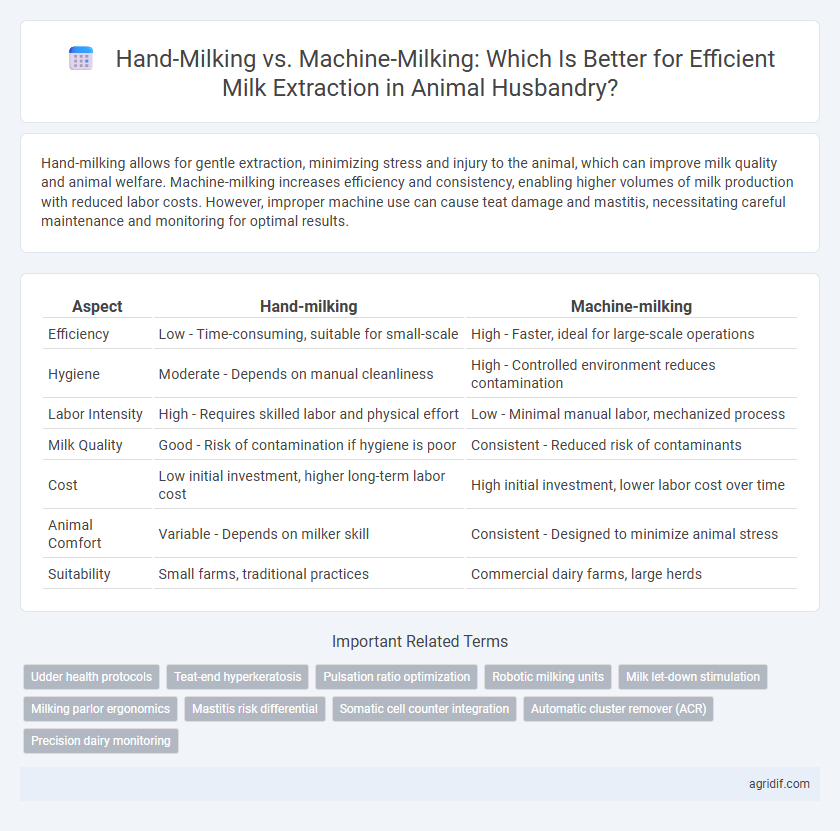

Hand-milking allows for gentle extraction, minimizing stress and injury to the animal, which can improve milk quality and animal welfare. Machine-milking increases efficiency and consistency, enabling higher volumes of milk production with reduced labor costs. However, improper machine use can cause teat damage and mastitis, necessitating careful maintenance and monitoring for optimal results.

Table of Comparison

| Aspect | Hand-milking | Machine-milking |

|---|---|---|

| Efficiency | Low - Time-consuming, suitable for small-scale | High - Faster, ideal for large-scale operations |

| Hygiene | Moderate - Depends on manual cleanliness | High - Controlled environment reduces contamination |

| Labor Intensity | High - Requires skilled labor and physical effort | Low - Minimal manual labor, mechanized process |

| Milk Quality | Good - Risk of contamination if hygiene is poor | Consistent - Reduced risk of contaminants |

| Cost | Low initial investment, higher long-term labor cost | High initial investment, lower labor cost over time |

| Animal Comfort | Variable - Depends on milker skill | Consistent - Designed to minimize animal stress |

| Suitability | Small farms, traditional practices | Commercial dairy farms, large herds |

Introduction to Milk Extraction Methods

Milk extraction methods primarily include hand-milking and machine-milking, each impacting milk yield and quality differently. Hand-milking, a traditional practice, relies on manual dexterity and is commonly used in small-scale dairy farms due to its low cost and simplicity. Machine-milking employs mechanical systems that enhance efficiency, consistency, and hygiene, making it the preferred choice in large-scale commercial dairy operations.

Overview of Hand-Milking Technique

Hand-milking involves manually extracting milk by rhythmically compressing the teats to stimulate milk flow, primarily used in small-scale farms or in situations lacking mechanized equipment. This technique demands skill and careful hygiene practices to prevent contamination and ensure udder health. Despite lower efficiency compared to machine milking, hand-milking offers increased control over the milking process, beneficial for detecting mastitis or abnormalities in individual animals.

Understanding Machine-Milking Systems

Machine-milking systems use automated milking machines equipped with vacuum pumps and pulsators to efficiently extract milk from dairy animals, ensuring consistent suction and rhythmic milking patterns that mimic natural suckling. These systems improve milking speed, hygiene, and reduce labor costs compared to traditional hand-milking methods, making them ideal for large-scale dairy operations. Regular maintenance of milking equipment and proper animal preparation are critical for optimizing milk quality and preventing mastitis.

Milk Yield: Hand-Milking vs Machine-Milking

Machine-milking consistently produces higher milk yield compared to hand-milking due to its ability to maintain steady vacuum pressure and rhythmic pulsation, ensuring efficient milk extraction. Hand-milking often results in lower yield as it depends on operator skill, strength, and endurance, which can lead to incomplete milk removal. Studies reveal machine-milking can increase milk yield by 10-15%, enhancing overall dairy farm productivity.

Impact on Animal Health and Udder Hygiene

Hand-milking promotes gentle extraction, reducing the risk of teat damage and mastitis, thereby improving udder health and hygiene. Machine-milking, while efficient, can cause teat stress and lesions if improperly adjusted, increasing susceptibility to infections. Proper maintenance of milking machines and adherence to hygiene protocols are critical to minimizing negative impacts on animal health.

Labor Efficiency and Time Considerations

Hand-milking in animal husbandry offers flexibility for small-scale operations but demands significantly more labor hours compared to machine-milking, which enhances productivity by extracting milk faster and reducing physical strain. Machine-milking systems can complete milk extraction within 5-7 minutes per cow, optimizing time management and enabling daily milking of larger herds without extensive labor costs. The scalability and consistent efficiency of machine-milking result in higher overall milk yield, crucial for commercial dairy farming where time and labor efficiency directly impact profitability.

Quality and Safety of Extracted Milk

Hand-milking preserves the natural microbiota of milk, reducing the risk of contamination when performed with proper hygiene, resulting in high-quality milk that is often preferred for artisanal dairy products. Machine-milking offers consistency and efficiency but requires rigorous cleaning and maintenance protocols to prevent bacterial growth and ensure the safety of the extracted milk. Both methods impact milk quality and safety differently, necessitating tailored management practices to optimize milk hygiene and nutritional value in animal husbandry.

Cost Analysis: Initial Investment and Maintenance

Hand-milking requires minimal initial investment, primarily involving simple tools like milking stools and buckets, resulting in lower startup costs compared to machine-milking. Machine-milking involves higher initial capital expenditure on equipment such as vacuum pumps and milking clusters, alongside ongoing maintenance costs for parts replacement, sanitation, and mechanical servicing. While hand-milking limits labor costs, machine-milking offers greater efficiency and scalability, making it more cost-effective for larger-scale dairy operations despite higher upfront and maintenance expenses.

Suitability for Small-Scale vs Large-Scale Farms

Hand-milking is highly suitable for small-scale farms due to its low cost, minimal equipment requirements, and ability to maintain close animal contact, which enhances milk hygiene and animal welfare. Machine-milking optimizes efficiency on large-scale farms by enabling faster milk extraction, uniform milking routines, and reduced labor costs, though it demands significant initial investment and technical maintenance. Small-scale producers benefit from hand-milking's simplicity, while commercial dairy operations leverage machine-milking for higher productivity and scalability.

Future Trends in Milking Technology

Emerging advancements in milking technology prioritize automated systems integrating AI-driven sensors and robotic arms to enhance milk yield and animal welfare while reducing labor costs. Future trends emphasize precision milking machines equipped with real-time health monitoring and udder condition analytics to optimize milk extraction efficiency. Research also explores sustainable energy-powered milking setups and data-driven herd management platforms to support eco-friendly and scalable dairy production.

Related Important Terms

Udder health protocols

Hand-milking requires meticulous hygiene practices such as thorough cleaning of teats and using sanitized equipment to minimize the risk of mastitis, while machine-milking protocols emphasize regular maintenance of milking machines and proper teat disinfection to ensure udder health. Implementing strict udder health protocols like post-milking teat dipping and timely monitoring for signs of infection enhances milk quality and reduces bacterial contamination in both methods.

Teat-end hyperkeratosis

Hand-milking causes less teat-end hyperkeratosis compared to machine-milking, which can lead to increased teat-end callusing and damage due to vacuum pressure and liner compression. Proper machine maintenance and milking protocols are essential to minimize hyperkeratosis and maintain udder health in dairy cows.

Pulsation ratio optimization

Optimizing the pulsation ratio in machine-milking enhances milk flow efficiency and teat health, typically maintaining a 60:40 milk to rest phase to closely mimic natural suckling patterns during hand-milking; improper ratios can cause teat tissue damage or inadequate milk extraction. Studies show that a balanced pulsation cycle improves udder health, increases milk yield, and reduces milking time compared to traditional hand-milking methods.

Robotic milking units

Robotic milking units enhance milk extraction by improving efficiency and animal welfare, allowing cows to be milked voluntarily multiple times a day, which increases overall milk yield. These systems utilize sensors and automated processes to monitor cow health and milk quality, reducing labor costs and minimizing stress compared to traditional hand-milking or conventional machine-milking methods.

Milk let-down stimulation

Hand-milking enhances milk let-down stimulation through manual teat massage and rhythmic squeezing, promoting oxytocin release and efficient milk flow. In contrast, machine-milking relies on vacuum pulsation systems that mimic suckling patterns but may require acclimatization to optimize oxytocin-triggered milk ejection reflex.

Milking parlor ergonomics

Hand-milking demands skilled manual labor with direct animal handling but often leads to inconsistent milk yield and increased worker fatigue due to repetitive motions and poor posture. Machine-milking systems in ergonomic milking parlors enhance efficiency by reducing physical strain, optimizing cow positioning, and ensuring standardized milk extraction, which improves overall productivity and animal welfare.

Mastitis risk differential

Hand-milking reduces mastitis risk by minimizing teat end damage and limiting bacterial contamination compared to machine-milking, which can cause teat injuries and ineffective milking if improperly maintained. Studies show machine-milking increases somatic cell counts and mastitis incidence, especially without stringent hygiene and equipment sanitation protocols.

Somatic cell counter integration

Hand-milking allows direct somatic cell counter (SCC) monitoring at the udder level, enabling immediate detection of mastitis, while machine-milking systems integrate automated SCC sensors for continuous, real-time milk quality assessment throughout the milking process. The integration of SCC data with machine-milking enhances herd health management by facilitating early intervention and improving milk hygiene standards.

Automatic cluster remover (ACR)

Automatic cluster removers (ACRs) in machine-milking systems significantly enhance milking efficiency by detaching the teat cups promptly once milk flow ceases, preventing over-milking and reducing udder stress. This technology improves udder health and milk quality compared to hand-milking, where manual detachment is less precise, often leading to prolonged milking and increased risk of mastitis.

Precision dairy monitoring

Hand-milking offers traditional tactile feedback for monitoring udder health but lacks the precision data provided by machine-milking systems, which utilize sensors to track milk flow, yield, and cow behavior in real-time. Precision dairy monitoring through machine-milking enhances early detection of mastitis, optimizes milking intervals, and improves overall herd management efficiency.

Hand-milking vs Machine-milking for Milk Extraction Infographic

agridif.com

agridif.com