On-farm mixing allows farmers to customize rations based on specific livestock needs and locally available ingredients, potentially reducing feed costs and improving nutrient utilization. Commercial feed offers consistent quality, balanced nutrition, and convenience, ensuring animals receive a complete diet without the need for on-site formulation expertise. Choosing between on-farm mixing and commercial feed depends on factors like scale, resource availability, and the precision of nutritional requirements for optimal animal performance.

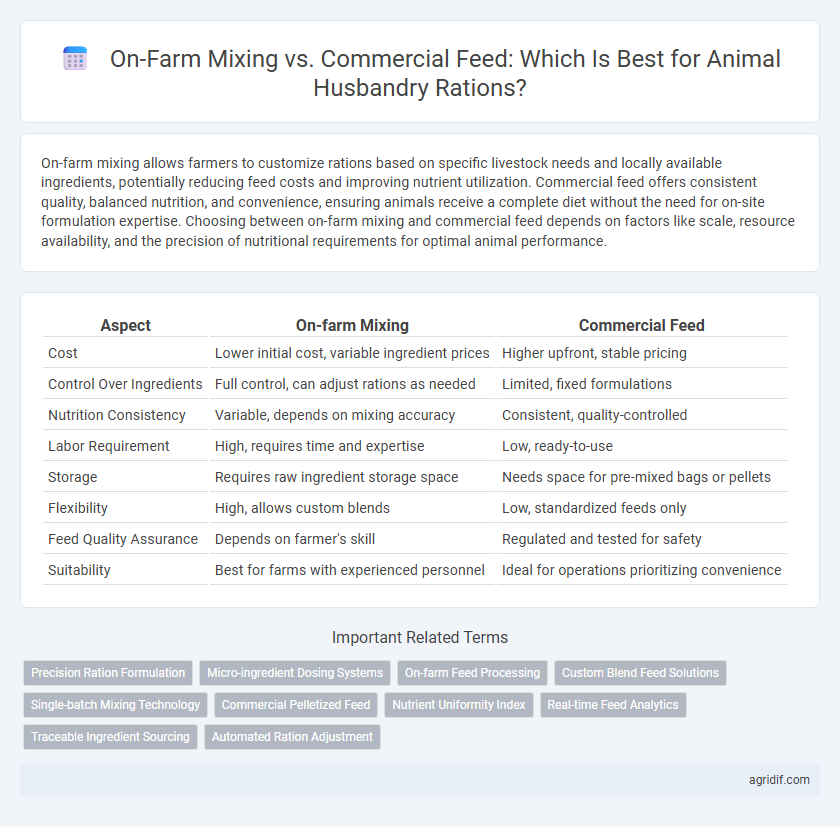

Table of Comparison

| Aspect | On-farm Mixing | Commercial Feed |

|---|---|---|

| Cost | Lower initial cost, variable ingredient prices | Higher upfront, stable pricing |

| Control Over Ingredients | Full control, can adjust rations as needed | Limited, fixed formulations |

| Nutrition Consistency | Variable, depends on mixing accuracy | Consistent, quality-controlled |

| Labor Requirement | High, requires time and expertise | Low, ready-to-use |

| Storage | Requires raw ingredient storage space | Needs space for pre-mixed bags or pellets |

| Flexibility | High, allows custom blends | Low, standardized feeds only |

| Feed Quality Assurance | Depends on farmer's skill | Regulated and tested for safety |

| Suitability | Best for farms with experienced personnel | Ideal for operations prioritizing convenience |

Overview of On-Farm Mixing and Commercial Feed

On-farm mixing allows farmers to customize rations using locally sourced ingredients, optimizing nutrient balance to specific livestock needs while potentially reducing costs. Commercial feed offers standardized nutrient profiles, consistent quality control, and convenient storage, ensuring reliable performance across different production scales. Both methods require careful formulation and quality assessment to maximize animal health, growth, and feed efficiency.

Nutritional Consistency in Animal Rations

On-farm mixing of animal rations often leads to variability in nutritional consistency due to inconsistent ingredient quality and mixing equipment limitations, impacting livestock growth and health. Commercial feed manufacturers utilize precise formulations and quality control measures to ensure uniform nutrient distribution in each batch, enhancing performance predictability. Consistent nutritional composition in animal rations is critical for maximizing feed efficiency, immune function, and overall production outcomes in livestock operations.

Cost Analysis: On-Farm Mixing vs Commercial Feed

On-farm mixing of rations often reduces feed costs by allowing farmers to source ingredients locally and tailor blends to specific livestock needs, resulting in savings compared to commercial feed prices. Commercial feeds typically carry higher costs due to processing, packaging, and transportation expenses, but offer consistent nutrient profiles and quality assurance. Cost analysis reveals on-farm mixing can enhance profitability if farmers efficiently manage ingredient procurement and blending precision.

Quality Control in Feed Preparation

On-farm mixing allows for tailored feed rations to meet specific nutritional needs but demands rigorous quality control to avoid nutrient imbalances and contamination. Commercial feed manufacturers implement standardized quality control protocols, including ingredient testing and consistency checks, ensuring uniform nutrient composition and safety. Balancing cost, precision, and feed quality is critical for optimal animal performance in both on-farm and commercial feed preparation methods.

Ingredient Sourcing and Storage Management

On-farm mixing allows direct control over ingredient sourcing, enabling farmers to select high-quality grains and supplements tailored to livestock nutritional needs, often reducing dependency on external suppliers. Storage management on the farm requires adequate facilities to prevent spoilage and contamination, necessitating investment in silos, bins, and climate control systems to maintain feed integrity. Commercial feed rations simplify logistics by delivering pre-mixed, quality-controlled products with standardized ingredient sourcing, though they limit customization and require less on-site storage infrastructure.

Flexibility and Customization of Rations

On-farm mixing of rations allows farmers to tailor feed composition precisely to the nutritional needs of their livestock, enhancing flexibility in ingredient selection and adjustment based on availability and cost. Customization supports optimizing animal performance and health by incorporating specific nutrient profiles and accommodating seasonal variations in feed resources. In contrast, commercial feed offers standardized formulations with limited adaptability, which may not meet unique or evolving dietary requirements as effectively as on-farm mixing.

Impact on Animal Health and Performance

On-farm mixing of rations allows precise customization of feed ingredients, directly addressing specific nutritional requirements which enhances animal health and growth performance. Commercial feeds offer consistent quality and balanced nutrient profiles, reducing the risk of contamination and nutrient deficiencies that can negatively impact productivity. Studies show that tailored on-farm mixes improve feed conversion ratios and immune response, while commercial feeds provide reliability in large-scale operations with standardized formulations.

Labor and Equipment Requirements

On-farm mixing of rations in animal husbandry requires significant labor input and investment in specialized mixing equipment, which can increase operational complexity and maintenance demands. Commercial feed offers convenience by eliminating the need for extensive on-site processing, reducing labor costs and equipment upkeep. Selecting the optimal feed strategy depends on balancing resource availability, labor capacity, and equipment infrastructure to maximize efficiency and cost-effectiveness in livestock nutrition management.

Regulatory Compliance and Feed Safety

On-farm mixing allows for customized rations tailored to specific herd needs but requires strict adherence to regulatory compliance standards such as FDA's Current Good Manufacturing Practices (cGMPs) to ensure feed safety. Commercial feed manufacturers follow rigorous audits and quality control protocols, minimizing risks of contamination and ensuring consistent nutrient profiles. Both methods demand diligent record-keeping and hazard analysis to meet animal health standards and prevent feed-borne illnesses.

Environmental Considerations and Sustainability

On-farm mixing of rations allows precise control over ingredient sourcing and formulation, reducing transportation emissions and plastic waste associated with commercial feed packaging. By utilizing locally available by-products and minimizing overfeeding, on-farm feed preparation supports nutrient cycling and lowers nitrogen and phosphorus runoff, mitigating environmental pollution. In contrast, commercial feeds often emphasize standardized nutrition but involve higher carbon footprints due to centralized manufacturing and long supply chains, presenting challenges for sustainable livestock management.

Related Important Terms

Precision Ration Formulation

Precision ration formulation in animal husbandry significantly benefits from on-farm mixing by allowing real-time adjustments based on animal performance and ingredient availability, enhancing nutrient accuracy and minimizing waste. Commercial feed offers consistent quality and balanced nutrition but may lack the customization flexibility needed to optimize specific herd requirements and local conditions.

Micro-ingredient Dosing Systems

Micro-ingredient dosing systems in on-farm mixing enable precise inclusion of vitamins, minerals, and additives tailored to specific herd requirements, enhancing feed efficiency and animal performance. Commercial feed rations offer consistency and quality control but often lack the customization flexibility provided by advanced on-farm dosing technologies, impacting nutrient optimization.

On-farm Feed Processing

On-farm feed processing allows livestock producers to customize rations tailored to specific nutritional requirements, improving feed efficiency and reducing dependency on commercial feeds. Utilizing local grains and by-products through on-farm mixing can lower costs, enhance control over ingredient quality, and support sustainable farm management practices.

Custom Blend Feed Solutions

Custom blend feed solutions in animal husbandry allow precise formulation of rations tailored to specific livestock nutritional needs, optimizing feed efficiency and promoting better health outcomes. On-farm mixing provides greater flexibility and cost control compared to commercial feed, enabling farmers to adjust ingredient proportions based on availability and price fluctuations while maintaining consistent nutrient profiles.

Single-batch Mixing Technology

Single-batch mixing technology enhances on-farm feed precision, ensuring consistent nutrient distribution and reducing feed waste compared to commercial rations. This method allows livestock producers to tailor mixtures to specific herd requirements, optimizing animal performance and health outcomes while minimizing costs.

Commercial Pelletized Feed

Commercial pelletized feed offers precisely formulated rations with consistent nutrient density, enhancing animal growth and productivity compared to on-farm mixing. The pelletized form improves feed intake efficiency, reduces waste, and ensures uniform distribution of essential vitamins and minerals critical for optimal livestock performance.

Nutrient Uniformity Index

On-farm mixing often results in lower nutrient uniformity index compared to commercial feed rations, which are formulated and blended under strict quality control to ensure consistent nutrient distribution. Maintaining a high nutrient uniformity index is crucial for optimal animal growth and production efficiency, making commercial feed a more reliable choice for precise nutritional management.

Real-time Feed Analytics

Real-time feed analytics enable precise monitoring of nutrient composition and feed intake in on-farm mixing, optimizing ration formulation to meet specific livestock requirements and improve animal performance. Commercial feed rations offer consistency but lack the adaptability of on-farm systems enhanced by real-time data, allowing dynamic adjustments to maximize feed efficiency and reduce waste.

Traceable Ingredient Sourcing

On-farm mixing enables precise control and traceability of ingredient sourcing, ensuring the feed components meet specific quality and safety standards, which is critical for compliance and animal health. Commercial feed often involves complex supply chains with less transparency, making it challenging to verify the origin and authenticity of each ingredient in the ration.

Automated Ration Adjustment

Automated ration adjustment systems enable precise nutrient blending on-farm, optimizing feed efficiency and reducing waste compared to static commercial feed rations. Real-time data integration and sensor feedback enhance formulation accuracy, promoting animal health and maximizing growth performance in livestock production.

On-farm Mixing vs Commercial Feed for Rations Infographic

agridif.com

agridif.com