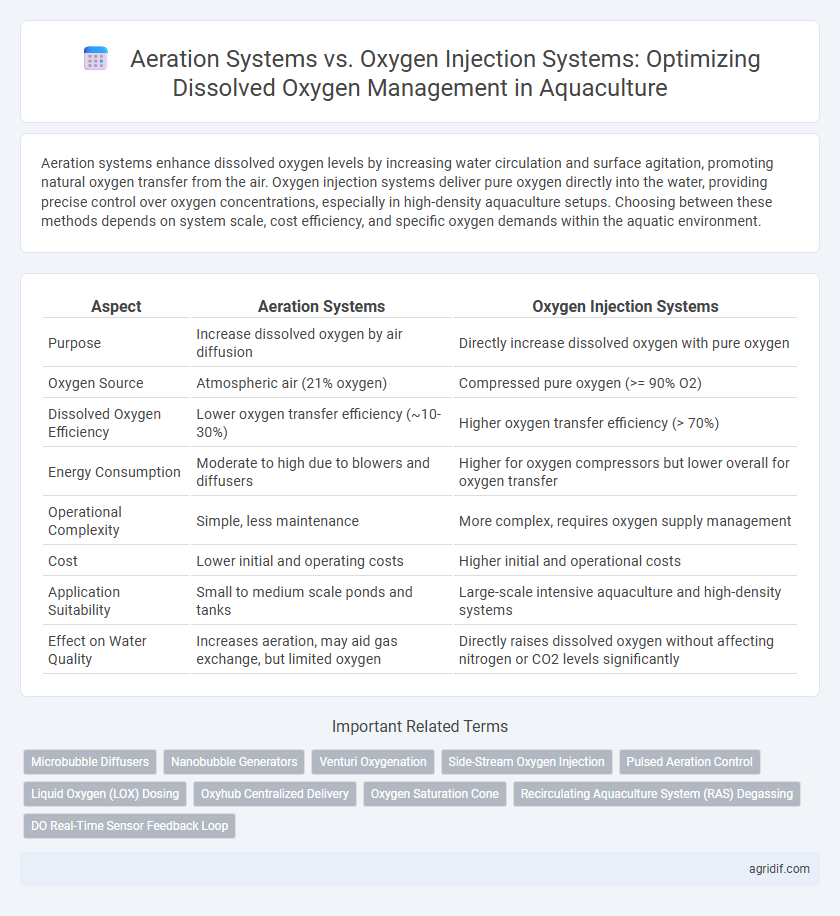

Aeration systems enhance dissolved oxygen levels by increasing water circulation and surface agitation, promoting natural oxygen transfer from the air. Oxygen injection systems deliver pure oxygen directly into the water, providing precise control over oxygen concentrations, especially in high-density aquaculture setups. Choosing between these methods depends on system scale, cost efficiency, and specific oxygen demands within the aquatic environment.

Table of Comparison

| Aspect | Aeration Systems | Oxygen Injection Systems |

|---|---|---|

| Purpose | Increase dissolved oxygen by air diffusion | Directly increase dissolved oxygen with pure oxygen |

| Oxygen Source | Atmospheric air (21% oxygen) | Compressed pure oxygen (>= 90% O2) |

| Dissolved Oxygen Efficiency | Lower oxygen transfer efficiency (~10-30%) | Higher oxygen transfer efficiency (> 70%) |

| Energy Consumption | Moderate to high due to blowers and diffusers | Higher for oxygen compressors but lower overall for oxygen transfer |

| Operational Complexity | Simple, less maintenance | More complex, requires oxygen supply management |

| Cost | Lower initial and operating costs | Higher initial and operational costs |

| Application Suitability | Small to medium scale ponds and tanks | Large-scale intensive aquaculture and high-density systems |

| Effect on Water Quality | Increases aeration, may aid gas exchange, but limited oxygen | Directly raises dissolved oxygen without affecting nitrogen or CO2 levels significantly |

Introduction to Dissolved Oxygen in Aquaculture

Dissolved oxygen (DO) is a critical parameter in aquaculture, essential for fish respiration and overall pond health. Aeration systems enhance DO by circulating and mixing water, increasing oxygen transfer from the atmosphere. Oxygen injection systems deliver pure oxygen directly, achieving higher DO levels rapidly, crucial for high-density aquaculture operations.

The Importance of Efficient Oxygen Management

Efficient oxygen management in aquaculture is critical for maintaining optimal dissolved oxygen levels, directly influencing fish health and growth rates. Aeration systems enhance oxygen transfer by increasing water circulation and surface area contact, while oxygen injection systems deliver pure oxygen for rapid concentration boosts, essential in high-density environments. Selecting the appropriate system depends on species requirements, water quality, and operational scale to ensure sustainable aquaculture practices.

Overview of Aeration Systems: Mechanisms and Types

Aeration systems enhance dissolved oxygen in aquaculture by mechanically mixing air with water, promoting gas exchange through surface agitation. Common types include diffused aerators, which release fine air bubbles through diffusers, paddlewheel aerators that agitate water surfaces, and spray aerators that increase oxygen absorption via water droplets. These systems improve oxygen availability essential for fish metabolism, growth, and overall pond health, offering cost-effective and adjustable solutions for dissolved oxygen management.

Overview of Oxygen Injection Systems: Technologies and Methods

Oxygen injection systems in aquaculture utilize technologies such as pure oxygen diffusers, oxygen cones, and oxygen microbubble generators to enhance dissolved oxygen levels efficiently. These methods deliver concentrated oxygen directly into water, improving oxygen transfer rates and reducing energy consumption compared to traditional aeration systems. Advanced oxygen injection provides precise control over dissolved oxygen concentrations, critical for optimizing fish health and growth in high-density aquaculture environments.

Comparative Analysis: Oxygen Transfer Efficiency

Aeration systems rely on diffused air bubbles to increase dissolved oxygen levels but often have lower oxygen transfer efficiency due to nitrogen dilution. Oxygen injection systems introduce pure oxygen directly into the water, significantly enhancing oxygen transfer rates and supporting higher biomass densities. Comparative studies show oxygen injection can achieve transfer efficiencies upwards of 90%, while traditional aeration typically ranges between 15% to 30%.

Energy Consumption: Aeration vs Oxygen Injection

Aeration systems typically consume more energy due to continuous operation and mechanical components like blowers and diffusers, which increase power usage in maintaining dissolved oxygen levels. Oxygen injection systems deliver pure oxygen directly into the water, reducing overall energy demands by minimizing air volume and enhancing oxygen transfer efficiency. Optimizing oxygen delivery through injection significantly lowers operational energy costs compared to conventional aeration in aquaculture dissolved oxygen management.

Impact on Water Quality and Fish Health

Aeration systems improve dissolved oxygen levels by increasing water circulation and surface oxygen exchange, enhancing overall water quality and reducing harmful gas accumulation. Oxygen injection systems deliver pure oxygen directly into the water, rapidly elevating oxygen concentration, which is beneficial for high-density fish farming and supports optimal fish metabolic functions. Both systems positively impact fish health by preventing hypoxia and promoting efficient respiration, but oxygen injection offers more precise control over dissolved oxygen levels, crucial for sensitive species and intensive aquaculture operations.

Cost Considerations and Long-Term Investment

Aeration systems typically require lower initial capital investment and have reduced operational costs due to simpler equipment and energy use. Oxygen injection systems, although involving higher upfront expenses, deliver more precise dissolved oxygen control, improving fish growth rates and reducing mortality long-term, which can offset initial costs through better productivity. Evaluating total cost of ownership, including maintenance, energy consumption, and production outcomes, is critical for selecting the optimal dissolved oxygen management approach in aquaculture operations.

Suitability for Different Aquaculture Systems

Aeration systems are ideal for ponds and earthen tanks where water movement and surface oxygen exchange are sufficient to maintain dissolved oxygen levels. Oxygen injection systems are more suitable for high-density recirculating aquaculture systems (RAS) and closed tanks requiring precise control of oxygen saturation. Each system's effectiveness depends on species-specific oxygen demand, stocking density, and system design parameters.

Future Trends in Dissolved Oxygen Management Technologies

Future trends in dissolved oxygen management for aquaculture emphasize advancements in aeration systems and oxygen injection technologies to enhance efficiency and sustainability. Innovations such as sensor-driven automation, real-time monitoring, and energy-efficient designs are being integrated to optimize oxygen levels and reduce operational costs. Emerging technologies like microbubble aeration and advanced oxygen atomizers promise improved gas transfer rates, supporting higher stocking densities and better fish health management.

Related Important Terms

Microbubble Diffusers

Microbubble diffusers in aeration systems enhance dissolved oxygen transfer efficiency by producing fine bubbles that increase oxygen solubility and distribution in aquaculture tanks. Compared to oxygen injection systems, microbubble diffusers offer improved oxygen diffusion rates and energy savings, promoting healthier aquatic environments and optimized fish growth.

Nanobubble Generators

Nanobubble generators enhance aeration systems by producing ultra-fine oxygen bubbles that increase dissolved oxygen levels more efficiently than traditional oxygen injection systems. These nanobubbles improve oxygen transfer rates, reduce energy consumption, and promote better fish health in aquaculture environments.

Venturi Oxygenation

Venturi oxygenation systems improve dissolved oxygen levels in aquaculture by creating a vacuum that efficiently mixes atmospheric oxygen with water, enhancing gas transfer rates compared to traditional aeration methods. These systems minimize energy consumption while maintaining optimal oxygen concentrations crucial for fish health and growth.

Side-Stream Oxygen Injection

Side-stream oxygen injection systems enhance dissolved oxygen levels in aquaculture by delivering pure oxygen directly into a recirculating water loop, optimizing oxygen utilization efficiency compared to traditional aeration systems that mix air into the main water flow. These systems reduce oxygen transfer limitations and improve fish health and growth rates by maintaining stable and higher dissolved oxygen concentrations critical for intensive aquaculture operations.

Pulsed Aeration Control

Pulsed aeration control in aquaculture enhances dissolved oxygen management by optimizing oxygen transfer efficiency and reducing energy consumption compared to traditional continuous aeration systems. Oxygen injection systems offer precise oxygen delivery, but pulsed aeration balances cost-effectiveness and environmental sustainability by modulating airflow based on real-time oxygen demand.

Liquid Oxygen (LOX) Dosing

Aeration systems increase dissolved oxygen levels by agitating water to enhance gas exchange at the surface, while oxygen injection systems, particularly Liquid Oxygen (LOX) dosing, deliver concentrated oxygen directly into aquaculture tanks, enabling precise control over oxygen concentrations and rapid response to demand fluctuations. LOX dosing optimizes oxygen utilization efficiency, reduces energy consumption, and minimizes off-gassing compared to traditional aeration, making it ideal for intensive aquaculture operations requiring stable dissolved oxygen management.

Oxyhub Centralized Delivery

Aeration systems rely on mechanical agitation to increase dissolved oxygen (DO) by enhancing gas exchange at the water surface, while oxygen injection systems, such as the Oxyhub Centralized Delivery, directly introduce pure oxygen into the water, resulting in more precise DO control and higher oxygen transfer efficiency. The Oxyhub system centralizes oxygen delivery for multiple tanks or ponds, reducing energy costs and improving overall aquaculture production sustainability through optimized oxygen utilization.

Oxygen Saturation Cone

Oxygen Saturation Cones in oxygen injection systems achieve higher dissolved oxygen levels by efficiently dissolving pure oxygen directly into water, surpassing the aeration systems that rely on atmospheric air and bubble diffusion methods. This targeted oxygen delivery enhances fish growth and reduces energy consumption compared to traditional aeration, optimizing aquaculture water quality management.

Recirculating Aquaculture System (RAS) Degassing

Aeration systems increase dissolved oxygen in Recirculating Aquaculture Systems (RAS) by facilitating gas exchange through bubble diffusion, effectively removing carbon dioxide but often limited by oxygen transfer efficiency. Oxygen injection systems directly elevate dissolved oxygen levels by introducing pure oxygen, offering precise control and enhanced degassing capacity critical for maintaining optimal water quality in intensive RAS operations.

DO Real-Time Sensor Feedback Loop

Aeration systems enhance water oxygenation by increasing air-water contact, while oxygen injection systems deliver pure oxygen directly, both relying on real-time dissolved oxygen (DO) sensor feedback loops for precise control and optimization. Integrating advanced DO sensors enables continuous monitoring and automated adjustments, ensuring optimal oxygen levels that improve fish health and maximize aquaculture productivity.

Aeration Systems vs Oxygen Injection Systems for dissolved oxygen management Infographic

agridif.com

agridif.com