Closed-loop aquaculture systems recycle water within the facility, significantly reducing water consumption and minimizing environmental impact through effective filtration and treatment processes. Open-loop systems continuously exchange water with the external environment, which can introduce pollutants and pathogens but allow for simpler waste removal and oxygen replenishment. Selecting between closed-loop and open-loop depends on balancing sustainability goals, water availability, and operational costs in aquaculture practices.

Table of Comparison

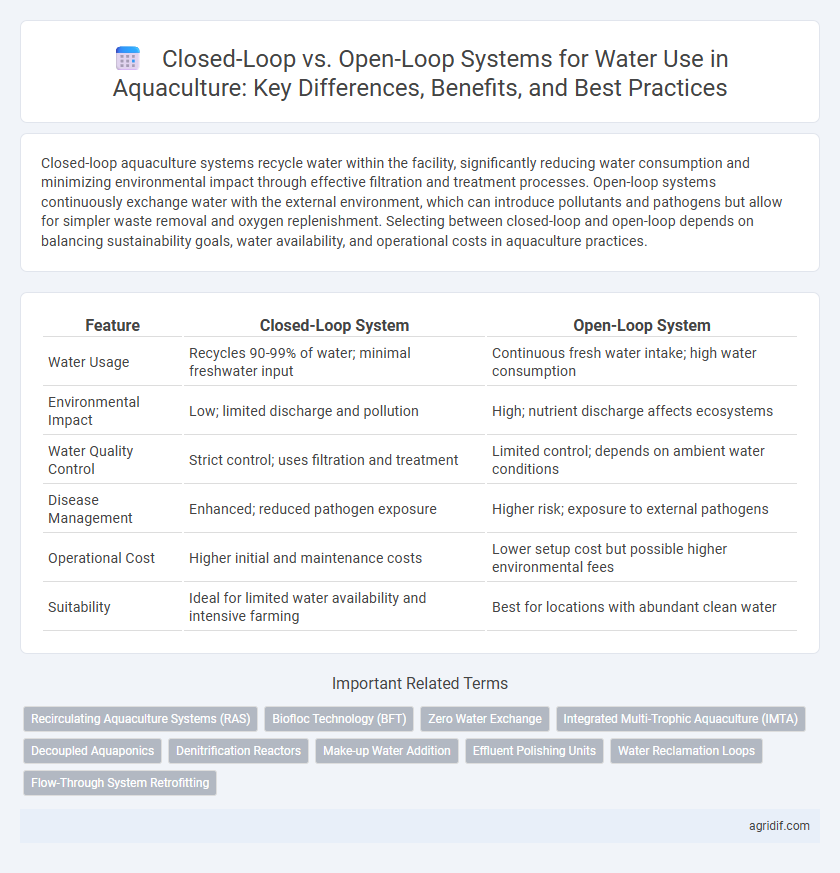

| Feature | Closed-Loop System | Open-Loop System |

|---|---|---|

| Water Usage | Recycles 90-99% of water; minimal freshwater input | Continuous fresh water intake; high water consumption |

| Environmental Impact | Low; limited discharge and pollution | High; nutrient discharge affects ecosystems |

| Water Quality Control | Strict control; uses filtration and treatment | Limited control; depends on ambient water conditions |

| Disease Management | Enhanced; reduced pathogen exposure | Higher risk; exposure to external pathogens |

| Operational Cost | Higher initial and maintenance costs | Lower setup cost but possible higher environmental fees |

| Suitability | Ideal for limited water availability and intensive farming | Best for locations with abundant clean water |

Introduction to Water Use in Aquaculture

Closed-loop aquaculture systems recycle water within the facility, drastically reducing freshwater consumption while maintaining optimal conditions for fish health and growth. Open-loop systems continuously exchange water with the external environment, which can lead to higher water usage and potential environmental impacts from effluent discharge. Efficient water management in aquaculture hinges on balancing system design with sustainability goals to minimize waste and preserve aquatic ecosystems.

Understanding Closed-Loop Aquaculture Systems

Closed-loop aquaculture systems recycle water within the facility, significantly reducing water consumption and minimizing environmental impact compared to open-loop systems that continuously discharge water. Advanced filtration technologies and biofiltration processes maintain water quality by removing waste, ammonia, and pathogens, ensuring optimal conditions for fish health and growth. These systems enhance sustainability and biosecurity by isolating production from external water sources, reducing the risk of contamination and disease transmission.

Overview of Open-Loop Aquaculture Systems

Open-loop aquaculture systems continuously exchange water with the surrounding environment, relying on natural water bodies to supply fresh water and remove waste, which helps maintain water quality without complex filtration. These systems are typically used in coastal or inland sites with abundant clean water sources, promoting efficient oxygenation and dilution of waste but posing risks of environmental impact through nutrient discharge. Open-loop systems offer simplicity and lower operational costs but require careful site selection and environmental monitoring to prevent ecological disturbances.

Water Conservation in Closed-Loop vs Open-Loop Systems

Closed-loop aquaculture systems recycle and treat water continuously, significantly reducing overall water consumption by minimizing discharge and reuse of nutrients within the system. In contrast, open-loop systems draw large volumes of fresh water from natural sources, leading to higher water use and potential environmental contamination due to untreated effluent release. Water conservation is maximized in closed-loop systems through advanced filtration and biofiltration technologies, promoting sustainable aquaculture with minimal freshwater dependency.

Environmental Impact Comparison

Closed-loop aquaculture systems recycle and treat water internally, drastically reducing water discharge and minimizing environmental contamination. Open-loop systems continuously exchange water with external sources, often leading to nutrient pollution, habitat disruption, and disease transfer in natural ecosystems. By limiting water exchange and controlling effluents, closed-loop systems offer a sustainable alternative with significantly lower ecological footprints compared to traditional open-loop setups.

Cost Efficiency and Operational Expenses

Closed-loop aquaculture systems significantly reduce water usage and discharge, leading to lower operational expenses despite higher initial capital costs. Open-loop systems benefit from simpler infrastructure and lower upfront investment but incur ongoing costs from water treatment and environmental compliance. Cost efficiency in aquaculture depends on balancing system design with water reuse capacity, waste management expenses, and local environmental regulations.

Water Quality Management and Control

Closed-loop aquaculture systems offer superior water quality management by continuously recycling and filtering water, significantly reducing contaminants and maintaining stable parameters such as pH, dissolved oxygen, and ammonia levels. Open-loop systems rely on constant water exchange with the environment, which can introduce pathogens and pollutants, making water quality control more challenging and dependent on external water conditions. Advanced filtration technologies and real-time monitoring in closed-loop systems optimize nutrient removal and waste breakdown, enhancing overall farm biosecurity and sustainability.

Disease Management and Biosecurity

Closed-loop aquaculture systems recirculate water within the facility, significantly reducing the risk of disease transmission by isolating pathogens and allowing precise control over water quality and sanitation. Open-loop systems discharge water directly into the environment, increasing exposure to external pathogens and complicating biosecurity efforts. Effective disease management in closed-loop systems relies on advanced filtration and disinfection technologies, whereas open-loop setups require robust monitoring and regional biosecurity protocols to mitigate infection risks.

Scalability and Adaptability of Each System

Closed-loop aquaculture systems offer superior scalability through efficient water reuse and controlled environments, enabling intensive production with minimal environmental impact. Open-loop systems rely on continuous water exchange with natural water bodies, limiting scalability due to dependency on water quality and availability, but provide adaptability to larger, less controlled settings. The choice between systems hinges on balancing operational control and ecological considerations to meet production goals.

Future Trends in Aquaculture Water Use Systems

Closed-loop systems in aquaculture recycle and treat water within the system, significantly reducing water consumption and minimizing environmental impact, which aligns with the industry's move toward sustainability and resource efficiency. Open-loop systems, while traditionally more common, are facing increased regulatory pressure due to water pollution and high freshwater demand. Future trends prioritize integrating advanced monitoring technologies and biofiltration in closed-loop systems to enhance water quality, reduce operational costs, and support large-scale, eco-friendly aquaculture production.

Related Important Terms

Recirculating Aquaculture Systems (RAS)

Recirculating Aquaculture Systems (RAS) utilize a closed-loop water treatment process that significantly reduces water consumption by continuously filtering and reusing water within the system, enhancing sustainability and biosecurity. In contrast, open-loop systems rely on a constant influx of fresh water and discharge wastewater, which increases environmental impact and resource use.

Biofloc Technology (BFT)

Closed-loop aquaculture systems using Biofloc Technology (BFT) optimize water reuse by recycling nutrients and maintaining water quality through microbial communities, significantly reducing water exchange compared to open-loop systems that rely on continuous water input and discharge. BFT enhances biosecurity and sustainability by minimizing environmental impact and improving feed conversion ratios in intensive fish and shrimp farming operations.

Zero Water Exchange

Closed-loop aquaculture systems maintain water quality by continuously filtering and reusing water within the system, achieving near zero water exchange and significantly reducing environmental impact. In contrast, open-loop systems rely on constant water replacement, leading to higher water consumption and potential contamination of natural water bodies.

Integrated Multi-Trophic Aquaculture (IMTA)

Closed-loop systems in Integrated Multi-Trophic Aquaculture (IMTA) recycle water internally, minimizing waste discharge and enhancing nutrient recovery through species like seaweed and bivalves that absorb excess nutrients. Open-loop systems draw water directly from and release it back into the environment, potentially causing nutrient pollution but offering simpler design and lower operational costs.

Decoupled Aquaponics

Decoupled aquaponics integrates closed-loop recirculating aquaculture systems with separate hydroponic units, optimizing water use by minimizing nutrient and water loss compared to open-loop systems, which continuously discharge wastewater into the environment. This approach enhances resource efficiency, reduces environmental impact, and allows precise control over water quality and nutrient recycling in aquaculture operations.

Denitrification Reactors

Closed-loop systems in aquaculture utilize denitrification reactors to efficiently remove nitrates through microbial processes, significantly reducing water discharge and environmental impact. Open-loop systems, by contrast, often lack such reactors, leading to higher nitrate levels in effluents and greater reliance on continuous water exchange.

Make-up Water Addition

Closed-loop aquaculture systems minimize make-up water addition by recycling and treating water within the system, significantly reducing freshwater demand and waste discharge. Open-loop systems rely heavily on continuous fresh water intake to maintain water quality, leading to higher consumption and potential environmental impacts.

Effluent Polishing Units

Closed-loop aquaculture systems utilize Effluent Polishing Units to treat and recycle water, significantly reducing environmental discharge and enhancing water quality by removing nutrients, organic matter, and pathogens. In contrast, open-loop systems discharge untreated effluent directly into natural water bodies, increasing the risk of pollution and ecosystem disruption.

Water Reclamation Loops

Closed-loop aquaculture systems maximize water reclamation by continuously filtering and recycling water within the system, significantly reducing freshwater consumption and minimizing environmental discharge. In contrast, open-loop systems rely on a constant influx of fresh water and direct discharge of wastewater, leading to higher water usage and potential ecological impact.

Flow-Through System Retrofitting

Flow-through systems in aquaculture continuously replace water, offering simplicity but high water consumption and effluent discharge, while retrofitting with closed-loop technologies enhances water reuse and reduces environmental impact by minimizing waste output. Integrating advanced filtration and recirculation components in flow-through systems optimizes water efficiency, supports sustainable practices, and addresses regulatory pressures on effluent management.

Closed-Loop vs Open-Loop Systems for water use Infographic

agridif.com

agridif.com