Aeration increases dissolved oxygen levels by introducing air into the water, promoting gas exchange at the surface, whereas oxygen injection delivers pure oxygen directly, resulting in faster and more efficient oxygenation. Aeration systems are generally more cost-effective and suitable for maintaining baseline oxygen levels, while oxygen injection is preferred in high-demand situations or emergency oxygen deficits. Selecting the optimal method depends on factors such as water volume, oxygen demand, and economic considerations in aquaculture operations.

Table of Comparison

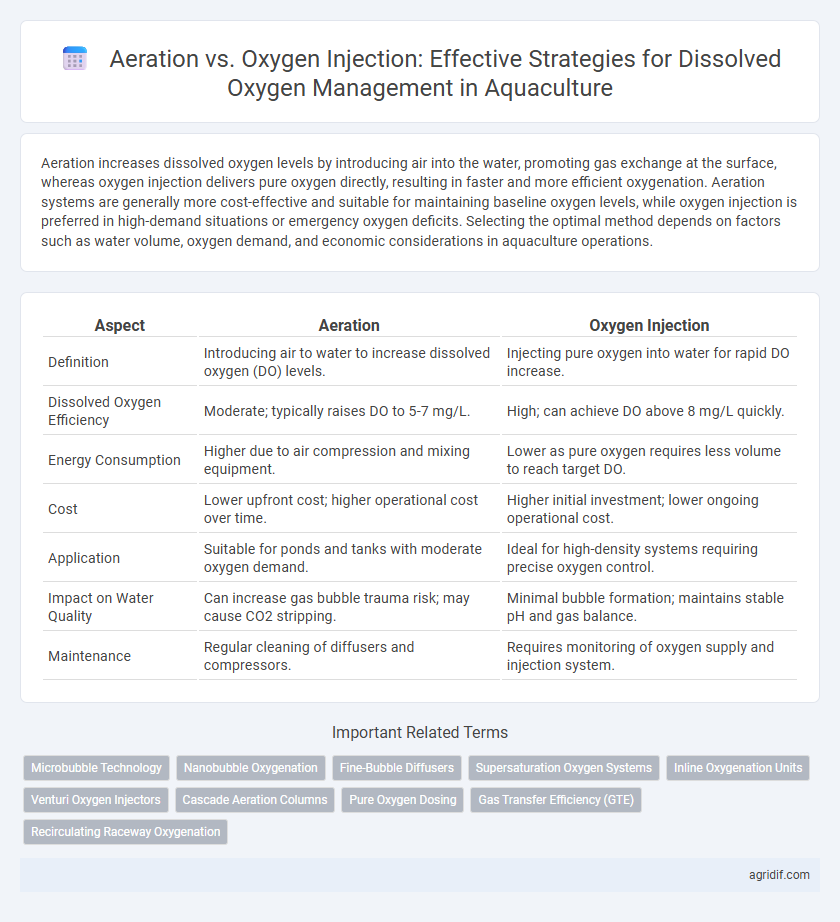

| Aspect | Aeration | Oxygen Injection |

|---|---|---|

| Definition | Introducing air to water to increase dissolved oxygen (DO) levels. | Injecting pure oxygen into water for rapid DO increase. |

| Dissolved Oxygen Efficiency | Moderate; typically raises DO to 5-7 mg/L. | High; can achieve DO above 8 mg/L quickly. |

| Energy Consumption | Higher due to air compression and mixing equipment. | Lower as pure oxygen requires less volume to reach target DO. |

| Cost | Lower upfront cost; higher operational cost over time. | Higher initial investment; lower ongoing operational cost. |

| Application | Suitable for ponds and tanks with moderate oxygen demand. | Ideal for high-density systems requiring precise oxygen control. |

| Impact on Water Quality | Can increase gas bubble trauma risk; may cause CO2 stripping. | Minimal bubble formation; maintains stable pH and gas balance. |

| Maintenance | Regular cleaning of diffusers and compressors. | Requires monitoring of oxygen supply and injection system. |

Understanding Dissolved Oxygen in Aquaculture

Dissolved oxygen (DO) is a critical parameter in aquaculture, directly influencing fish health, growth, and survival rates. Aeration increases DO by enhancing gas exchange at the water surface, while oxygen injection delivers concentrated oxygen directly into the water, rapidly raising DO levels in high-density systems. Effective DO management balances cost, system design, and species requirements to optimize aquaculture productivity and prevent hypoxia-related losses.

The Role of Aeration in Oxygen Management

Aeration plays a crucial role in maintaining optimal dissolved oxygen levels in aquaculture systems by enhancing gas exchange at the water surface and promoting oxygen diffusion throughout the water column. Mechanical aerators, such as paddle wheels and diffused air systems, increase turbulence and surface area, facilitating oxygen transfer from the atmosphere into the water. Effective aeration supports fish health, improves feed conversion ratios, and minimizes stress by preventing hypoxic conditions in ponds and tanks.

What is Oxygen Injection Technology?

Oxygen injection technology involves directly adding pure oxygen into aquaculture systems to maintain optimal dissolved oxygen levels, enhancing fish growth and health. This method provides precise control over oxygen concentrations, reducing energy consumption compared to traditional aeration techniques. It is especially effective in high-density aquaculture environments where oxygen demands are elevated.

Key Differences: Aeration vs Oxygen Injection

Aeration introduces atmospheric air into water, increasing dissolved oxygen levels gradually by promoting gas exchange through bubbles, while oxygen injection supplies pure oxygen directly, achieving faster and higher dissolved oxygen concentrations essential for high-density aquaculture systems. Aeration is energy-efficient and suitable for lower oxygen demands, but oxygen injection offers precise control and supports rapid oxygen replenishment during critical stress periods. The choice depends on species oxygen requirements, system volume, and operational costs, with oxygen injection providing superior performance in intensive aquaculture environments.

Efficiency of Oxygen Transfer Methods

Aeration methods in aquaculture facilitate oxygen dissolution through agitation and water-air interface exposure, but often with lower transfer efficiency due to oxygen losses to the atmosphere. Oxygen injection techniques, such as pure oxygen diffusers or microbubble generators, achieve higher dissolved oxygen levels rapidly by directly delivering concentrated oxygen into the water, minimizing gas escape. Studies indicate oxygen injection can improve oxygen transfer efficiency by up to 30-50% compared to traditional aeration, optimizing conditions for intensive aquaculture systems.

Energy Consumption and Cost Analysis

Aeration systems typically consume more energy due to continuous air pumping and diffusion processes, leading to higher operational costs compared to oxygen injection methods that deliver pure oxygen directly, increasing efficiency. Oxygen injection reduces energy expenditure by requiring lower flow rates to achieve optimal dissolved oxygen levels, resulting in significant cost savings in large-scale aquaculture operations. Investment in oxygen injection equipment may incur higher upfront costs but offers long-term financial benefits through reduced energy consumption and enhanced fish growth rates.

Impact on Fish Health and Growth

Aeration increases dissolved oxygen levels by enhancing water circulation and surface gas exchange, supporting fish metabolism and promoting optimal growth rates. Oxygen injection delivers pure oxygen directly into the water, achieving higher dissolved oxygen concentrations essential for intensive aquaculture systems and reducing stress-related diseases. Proper management of dissolved oxygen through these methods significantly improves fish immune response, reduces mortality rates, and enhances feed conversion efficiency.

Suitability for Different Aquaculture Systems

Aeration suits extensive and semi-intensive aquaculture systems by promoting uniform oxygen distribution through surface agitation and water circulation, optimizing dissolved oxygen levels in ponds and raceways. Oxygen injection proves ideal for intensive systems, such as recirculating aquaculture systems (RAS) and high-density cages, delivering precise and concentrated oxygen directly into the water, enhancing oxygen availability under high biomass conditions. Selecting between aeration and oxygen injection depends on system scale, stocking density, oxygen demand, and economic considerations, ensuring efficient dissolved oxygen management tailored to specific aquaculture environments.

Maintenance and Operational Considerations

Aeration systems in aquaculture typically require regular cleaning and monitoring to prevent clogging and ensure efficient oxygen transfer, demanding moderate maintenance efforts. Oxygen injection systems, although more complex and costly, offer precise dissolved oxygen control with less frequent maintenance but require specialized equipment and skilled operation. Operational considerations include the energy consumption and responsiveness of each system, with oxygen injection providing faster oxygen level adjustments compared to aeration.

Choosing the Right Solution for Your Aquaculture Operation

Aeration and oxygen injection are critical for maintaining optimal dissolved oxygen levels in aquaculture systems, directly impacting fish growth and health. Aeration systems enhance gas exchange by increasing water surface agitation, ideal for low to moderate oxygen demands, while oxygen injection delivers pure oxygen directly, supporting high-density stocking and rapid oxygen replenishment. Selecting the right solution depends on factors such as pond size, species oxygen requirements, water temperature, and budget constraints to ensure efficient and sustainable oxygen management.

Related Important Terms

Microbubble Technology

Microbubble technology enhances aeration and oxygen injection efficiency by producing ultra-fine bubbles that increase dissolved oxygen levels in aquaculture systems, promoting faster gas transfer and reducing energy consumption. This innovative method outperforms traditional aeration by maximizing oxygen solubility and distribution, leading to improved fish health and growth rates.

Nanobubble Oxygenation

Nanobubble oxygenation enhances dissolved oxygen levels in aquaculture by producing ultra-fine bubbles that increase oxygen transfer efficiency and retention time compared to traditional aeration or oxygen injection methods. This technology improves water quality, promotes healthier aquatic species growth, and reduces energy consumption in sustainable fish farming practices.

Fine-Bubble Diffusers

Fine-bubble diffusers in aquaculture enhance dissolved oxygen levels by producing smaller, more persistent bubbles that increase oxygen transfer efficiency compared to larger bubbles from coarse aeration. Oxygen injection through fine-bubble diffusers significantly improves water quality and fish health by maintaining optimal dissolved oxygen concentrations critical for high-density aquaculture systems.

Supersaturation Oxygen Systems

Supersaturation oxygen systems in aquaculture provide precise control over dissolved oxygen levels by injecting pure oxygen directly into water, resulting in higher oxygen transfer efficiency and reduced gas bubble disease compared to traditional aeration methods. These systems enable improved fish growth and health by maintaining optimal oxygen concentrations, minimizing energy consumption and environmental impact.

Inline Oxygenation Units

Inline oxygenation units enhance dissolved oxygen levels more efficiently than traditional aeration by directly injecting concentrated oxygen into water, improving fish health and growth rates. These systems reduce energy consumption and optimize oxygen transfer efficiency, crucial for maintaining stable aquatic environments in intensive aquaculture operations.

Venturi Oxygen Injectors

Venturi oxygen injectors enhance aquaculture dissolved oxygen levels by efficiently mixing oxygen into water, outperforming traditional aeration methods which rely on ambient air diffusion. This technology ensures higher oxygen transfer rates and precise control, optimizing fish health and productivity in intensive aquaculture systems.

Cascade Aeration Columns

Cascade aeration columns efficiently increase dissolved oxygen levels in aquaculture systems by promoting gas exchange through water cascading over multiple steps, enhancing oxygen saturation without requiring high energy inputs. Unlike oxygen injection methods, cascade aeration offers a cost-effective and sustainable solution, reducing the risk of oxygen toxicity while maintaining optimal aquatic health and preventing stress on fish and other marine organisms.

Pure Oxygen Dosing

Pure oxygen dosing enhances dissolved oxygen levels more efficiently than aeration by introducing concentrated oxygen directly into the water, minimizing gas wastage and energy consumption. This method supports higher fish densities and improves growth rates in aquaculture systems by maintaining optimal oxygen saturation with precise control.

Gas Transfer Efficiency (GTE)

Aeration systems typically achieve Gas Transfer Efficiency (GTE) rates between 10-30%, utilizing fine bubble diffusion to enhance oxygen dissolution in aquaculture tanks, while oxygen injection methods deliver significantly higher GTE, often exceeding 70%, through direct microbubble or pure oxygen introduction. Optimizing GTE in dissolved oxygen management directly improves fish respiration efficiency and reduces energy consumption in aquaculture operations.

Recirculating Raceway Oxygenation

Recirculating Raceway Oxygenation (RRO) enhances dissolved oxygen through fine bubble oxygen injection, providing higher transfer efficiency compared to conventional aeration methods that rely on atmospheric air mixing. Oxygen injection in RRO systems supports optimal fish growth and health by maintaining stable dissolved oxygen levels essential for intensive aquaculture environments.

Aeration vs Oxygen injection for dissolved oxygen management Infographic

agridif.com

agridif.com