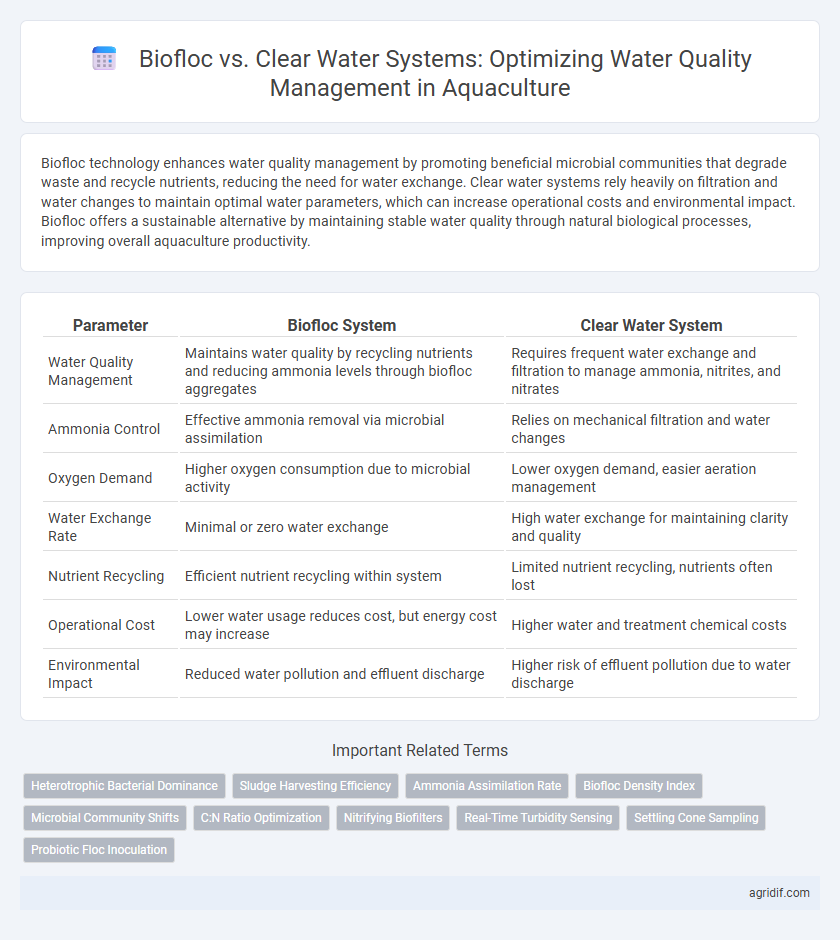

Biofloc technology enhances water quality management by promoting beneficial microbial communities that degrade waste and recycle nutrients, reducing the need for water exchange. Clear water systems rely heavily on filtration and water changes to maintain optimal water parameters, which can increase operational costs and environmental impact. Biofloc offers a sustainable alternative by maintaining stable water quality through natural biological processes, improving overall aquaculture productivity.

Table of Comparison

| Parameter | Biofloc System | Clear Water System |

|---|---|---|

| Water Quality Management | Maintains water quality by recycling nutrients and reducing ammonia levels through biofloc aggregates | Requires frequent water exchange and filtration to manage ammonia, nitrites, and nitrates |

| Ammonia Control | Effective ammonia removal via microbial assimilation | Relies on mechanical filtration and water changes |

| Oxygen Demand | Higher oxygen consumption due to microbial activity | Lower oxygen demand, easier aeration management |

| Water Exchange Rate | Minimal or zero water exchange | High water exchange for maintaining clarity and quality |

| Nutrient Recycling | Efficient nutrient recycling within system | Limited nutrient recycling, nutrients often lost |

| Operational Cost | Lower water usage reduces cost, but energy cost may increase | Higher water and treatment chemical costs |

| Environmental Impact | Reduced water pollution and effluent discharge | Higher risk of effluent pollution due to water discharge |

Introduction to Biofloc and Clear Water Systems

Biofloc and clear water systems represent two distinct approaches to water quality management in aquaculture. Biofloc technology enhances water quality by promoting the growth of beneficial microbial communities that convert waste compounds into usable protein, reducing ammonia and nitrite levels naturally. Clear water systems rely on mechanical and biological filtration to maintain water clarity and remove waste, requiring frequent water exchange to sustain optimal conditions for aquatic species.

Principles of Water Quality in Aquaculture

Biofloc technology enhances water quality management by promoting beneficial microbial communities that recycle nitrogenous wastes into microbial protein, reducing toxic ammonia and nitrite levels. In contrast, clear water systems rely on frequent water exchange and mechanical filtration to maintain optimal dissolved oxygen, pH, and low turbidity. Effective water quality principles in aquaculture emphasize maintaining stable physicochemical parameters and minimizing toxic metabolites to ensure healthy aquatic species growth.

Biofloc Technology: Mechanisms and Benefits

Biofloc technology enhances water quality management in aquaculture by promoting beneficial microbial communities that convert waste products like ammonia and nitrites into microbial biomass, reducing toxicity and improving nutrient recycling. The dense microbial aggregates in biofloc systems serve as a natural biofilter, maintaining optimal dissolved oxygen levels and minimizing water exchange requirements compared to clear water systems. This approach not only mitigates environmental impact but also supports higher stocking densities and improves overall fish health and growth performance.

Clear Water System: Features and Limitations

The Clear Water System in aquaculture maintains water quality through continuous filtration and water exchange, minimizing suspended solids and controlling nutrients to support optimal fish health. It features mechanical and biological filters that reduce organic waste and maintain dissolved oxygen levels, promoting stable aquatic environments. However, limitations include high operational costs, increased water consumption, and vulnerability to sudden water quality fluctuations due to less microbial activity compared to biofloc systems.

Nutrient Management in Biofloc vs Clear Water

Biofloc technology enhances nutrient management by converting excess nitrogen and organic waste into microbial protein, reducing harmful nitrogen compounds and improving water quality in aquaculture systems. Clear water systems rely heavily on water exchange and filtration to remove nutrients, often requiring more frequent water replacement and higher operational costs. Biofloc maintains nutrient balance through microbial activity, promoting sustainable and cost-effective water quality management compared to conventional clear water methods.

Microbial Communities: Differences and Impacts

Biofloc systems enhance microbial communities by promoting beneficial bacteria that improve water quality through nitrogen cycling and pathogen suppression, contrasting with clear water systems that rely heavily on mechanical filtration and chemical treatments. The diverse microbial ecosystem in biofloc supports nutrient recycling, reduces harmful ammonia levels, and stabilizes pH, fostering a healthier aquatic environment. In clear water management, microbial diversity is typically lower, leading to increased susceptibility to water quality fluctuations and disease outbreaks.

Water Parameters: Monitoring and Control Strategies

In aquaculture, biofloc systems improve water quality by maintaining optimal levels of ammonia, nitrite, and nitrate through microbial aggregation, reducing the need for frequent water exchange compared to clear water systems. Continuous monitoring of pH, dissolved oxygen, and turbidity is essential in biofloc environments to prevent toxic accumulation and ensure microbial balance. Clear water systems rely more heavily on mechanical filtration and water replacement to manage water parameters, demanding precise control to avoid rapid fluctuations that can stress cultured species.

Environmental Sustainability Comparison

Biofloc technology enhances water quality by promoting microbial communities that recycle nutrients and reduce harmful waste, leading to lower water exchange rates compared to clear water systems. This method minimizes environmental impact through decreased water usage, reduced effluent discharge, and improved resource efficiency, supporting sustainable aquaculture practices. In contrast, clear water systems often require higher water exchange and chemical treatments, potentially increasing ecological disturbances and resource consumption.

Economic Considerations: Cost and Resource Use

Biofloc technology reduces water exchange, lowering water treatment and sourcing costs compared to clear water systems that require frequent water renewal and filtration. The recirculating microbial communities in biofloc efficiently recycle nutrients, minimizing feed waste and improving feed conversion ratios, which decreases overall input costs. Clear water systems incur higher energy and labor expenses due to continuous aeration and water quality monitoring, making biofloc more cost-effective for sustainable aquaculture operations.

Choosing the Right System for Your Farm

Biofloc technology enhances water quality by promoting microbial communities that convert waste into beneficial nutrients, reducing the need for water exchange and lowering environmental impact. Clear water systems require frequent water replacement and sophisticated filtration to maintain optimal conditions, increasing operational costs and resource use. Selecting the appropriate system depends on farm size, budget, species cultured, and desired sustainability goals, with biofloc offering cost-effective nutrient recycling and clear water ensuring higher initial water clarity.

Related Important Terms

Heterotrophic Bacterial Dominance

Biofloc systems promote heterotrophic bacterial dominance by converting organic waste into microbial protein, enhancing water quality through nutrient recycling and reducing nitrogenous compounds. In contrast, clear water systems rely on frequent water exchanges and chemical treatments, often resulting in lower microbial diversity and less efficient nitrogen removal.

Sludge Harvesting Efficiency

Biofloc systems enhance sludge harvesting efficiency by promoting microbial aggregation that consolidates organic waste into dense flocs, enabling easier removal and reducing nutrient accumulation. In contrast, clear water systems require frequent mechanical filtration to manage suspended solids, often resulting in lower sludge recovery and increased operational costs.

Ammonia Assimilation Rate

Biofloc systems exhibit a higher ammonia assimilation rate compared to clear water systems due to the dense microbial community that rapidly converts toxic ammonia into microbial biomass. This enhanced ammonia removal improves water quality and supports sustainable aquaculture production by reducing the need for water exchange and chemical treatments.

Biofloc Density Index

The Biofloc Density Index (BDI) is a critical parameter in aquaculture water quality management, representing the concentration of microbial flocs that enhance nutrient cycling and improve water quality by reducing harmful nitrogen compounds. Biofloc systems maintain higher BDI levels compared to clear water systems, fostering beneficial microbial communities that optimize ammonia assimilation and promote sustainable aquaculture production.

Microbial Community Shifts

Biofloc systems enhance water quality management by promoting beneficial microbial community shifts that improve nutrient recycling and reduce harmful pathogens, unlike clear water systems which require frequent water exchanges and chemical interventions. The diverse microbial consortia in biofloc environments increase organic matter decomposition and maintain stable water parameters, leading to sustainable aquaculture practices.

C:N Ratio Optimization

Biofloc technology enhances water quality management by maintaining an optimal carbon-to-nitrogen (C:N) ratio, promoting microbial growth that assimilates nitrogenous wastes and reduces ammonia levels. In contrast, clear water systems require frequent water exchange and chemical treatments to control nitrogen compounds, often leading to higher operational costs and environmental impact.

Nitrifying Biofilters

Nitrifying biofilters in biofloc systems enhance ammonia and nitrite removal by promoting beneficial microbial communities, leading to improved water quality and reduced toxicity in aquaculture ponds. Clear water systems rely on mechanical filtration and water exchange, which can be less efficient in maintaining stable nitrogen levels compared to the continuous biological nitrification process within biofloc environments.

Real-Time Turbidity Sensing

Biofloc systems leverage continuous microbial activity to maintain lower turbidity fluctuations, enhancing real-time turbidity sensing accuracy for proactive water quality management. Clear water systems depend on mechanical filtration and chemical treatments, often resulting in more variable turbidity levels that challenge precise real-time sensing and swift response.

Settling Cone Sampling

Biofloc systems enhance water quality management by promoting microbial flocculation, which can be efficiently monitored using settling cone sampling to assess suspended solids concentration and floc settleability. In contrast, clear water systems rely on mechanical filtration and sedimentation, where settling cone sampling primarily measures particulate matter accumulation without significant microbial aggregation.

Probiotic Floc Inoculation

Probiotic floc inoculation in biofloc systems enhances water quality by promoting beneficial microbial communities that rapidly degrade organic waste and reduce harmful pathogens, leading to lower ammonia and nitrite levels compared to clear water systems. This microbial-driven approach improves nutrient cycling and water stability, minimizing the need for frequent water exchange and resulting in a more sustainable and efficient aquaculture environment.

Biofloc vs Clear water for water quality management Infographic

agridif.com

agridif.com