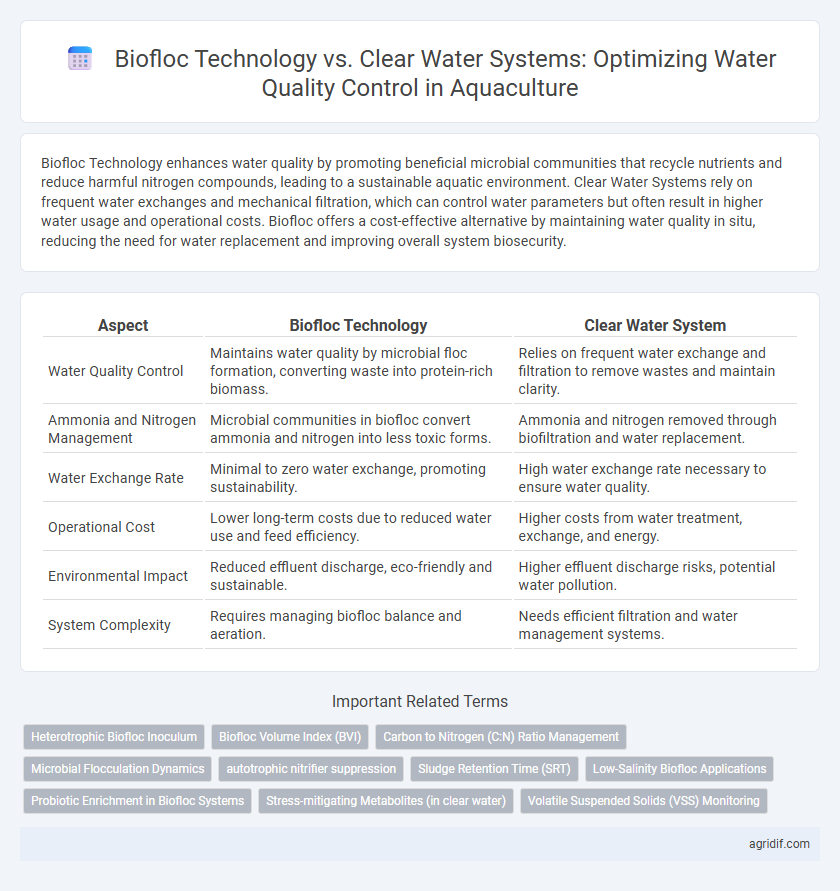

Biofloc Technology enhances water quality by promoting beneficial microbial communities that recycle nutrients and reduce harmful nitrogen compounds, leading to a sustainable aquatic environment. Clear Water Systems rely on frequent water exchanges and mechanical filtration, which can control water parameters but often result in higher water usage and operational costs. Biofloc offers a cost-effective alternative by maintaining water quality in situ, reducing the need for water replacement and improving overall system biosecurity.

Table of Comparison

| Aspect | Biofloc Technology | Clear Water System |

|---|---|---|

| Water Quality Control | Maintains water quality by microbial floc formation, converting waste into protein-rich biomass. | Relies on frequent water exchange and filtration to remove wastes and maintain clarity. |

| Ammonia and Nitrogen Management | Microbial communities in biofloc convert ammonia and nitrogen into less toxic forms. | Ammonia and nitrogen removed through biofiltration and water replacement. |

| Water Exchange Rate | Minimal to zero water exchange, promoting sustainability. | High water exchange rate necessary to ensure water quality. |

| Operational Cost | Lower long-term costs due to reduced water use and feed efficiency. | Higher costs from water treatment, exchange, and energy. |

| Environmental Impact | Reduced effluent discharge, eco-friendly and sustainable. | Higher effluent discharge risks, potential water pollution. |

| System Complexity | Requires managing biofloc balance and aeration. | Needs efficient filtration and water management systems. |

Introduction to Biofloc Technology and Clear Water Systems

Biofloc technology enhances water quality by promoting beneficial microbial communities that convert waste into protein-rich biomass, reducing nitrogenous compounds and minimizing water exchange. Clear water systems rely on physical filtration and regular water replacement to maintain transparency and control pollutants, but often require higher water usage and energy input. Both methods aim to optimize aquaculture environments, with biofloc offering sustainable nutrient recycling and clear water systems emphasizing mechanical water purification.

Principles of Water Quality Control in Aquaculture

Biofloc Technology enhances water quality control by promoting beneficial microbial communities that convert nitrogenous wastes into microbial protein, reducing toxic ammonia and nitrite levels in aquaculture systems. In contrast, the Clear Water System relies on physical filtration and frequent water exchange to maintain low concentrations of suspended solids and dissolved wastes. Both systems aim to optimize parameters such as dissolved oxygen, pH, and nutrient balance, but Biofloc provides a sustainable, waste-recycling approach while Clear Water emphasizes external water quality management.

Mechanisms of Biofloc Technology for Waste Management

Biofloc Technology utilizes microbial communities to convert organic waste and uneaten feed into microbial biomass, effectively reducing ammonia and nitrite levels in aquaculture ponds. This process promotes natural biofiltration by heterotrophic bacteria that assimilate nitrogenous compounds, maintaining optimal water quality without frequent water exchange. The continuous recycling of nutrients in biofloc systems enhances waste management compared to Clear Water Systems, which rely primarily on physical filtration and water renewal.

Water Purification Processes in Clear Water Systems

Clear Water Systems rely on mechanical filtration, biofilters, and regular water exchange to maintain optimal water quality by removing solids and ammonia. In these systems, biofilters convert toxic ammonia into less harmful nitrates through nitrification, while mechanical filters trap suspended particles, ensuring water clarity. Continuous monitoring and controlled water replacement prevent the buildup of organic waste and maintain stable physicochemical parameters crucial for aquaculture health.

Nutrient Cycling: Biofloc vs Clear Water Approaches

Biofloc technology enhances nutrient cycling by promoting microbial communities that convert organic waste and excess nutrients into microbial protein, improving water quality and reducing feed costs. In contrast, the clear water system relies on frequent water exchange and mechanical filtration to maintain water quality, which can lead to nutrient loss and higher operational costs. Biofloc promotes a sustainable, closed-loop nutrient management approach, whereas clear water systems require constant external input to control nutrient levels.

Impact on Fish and Shrimp Health

Biofloc Technology enhances water quality by promoting beneficial microbial communities that suppress harmful pathogens, leading to improved immune responses and reduced disease outbreaks in fish and shrimp. In contrast, Clear Water Systems rely on frequent water exchange and filtration, which can limit microbial diversity and increase stress due to fluctuating water parameters. Studies indicate that biofloc systems result in better growth rates and higher survival percentages by maintaining stable water quality conditions essential for aquatic animal health.

Operational Costs and Resource Efficiency

Biofloc Technology reduces operational costs by recycling nutrients within the system, minimizing water exchange and feed requirements compared to the Clear Water System, which demands higher water usage and frequent filtration. Resource efficiency in Biofloc relies on microbial flocs to maintain water quality, promoting sustainable waste management and reduced environmental impact. The Clear Water System incurs increased expenses due to continuous water treatment and aeration, limiting its efficiency in resource conservation.

Environmental Sustainability and Footprint

Biofloc Technology significantly enhances environmental sustainability by recycling nutrients and reducing water exchange, minimizing pollution and conserving freshwater resources compared to the Clear Water System. This approach lowers the carbon footprint through decreased reliance on external feed and energy-intensive water treatment processes typical of Clear Water Systems. Moreover, Biofloc's in-situ microbial management promotes a balanced ecosystem, reducing effluent discharge and supporting long-term aquaculture viability.

Challenges and Limitations of Each System

Biofloc Technology faces challenges such as maintaining optimal carbon-to-nitrogen ratios and managing sludge accumulation, which can lead to water quality deterioration if not properly controlled. Clear Water Systems demand extensive water exchange and filtration, resulting in higher operational costs and increased vulnerability to water source contamination. Both systems require precise monitoring to prevent ammonia toxicity and disease outbreaks, yet Biofloc offers better nutrient recycling while Clear Water emphasizes water clarity and reduced suspended solids.

Choosing the Right System: Factors to Consider in Aquaculture

Biofloc Technology enhances water quality by promoting beneficial microbial communities that recycle nitrogenous waste, reducing the need for water exchange and minimizing environmental impact. Clear Water Systems rely on frequent water exchange and filtration to maintain optimal water parameters, requiring higher water usage and energy inputs. When choosing the right system, factors such as water availability, energy costs, species cultured, and environmental sustainability should be carefully evaluated to optimize productivity and maintain water quality in aquaculture operations.

Related Important Terms

Heterotrophic Biofloc Inoculum

Heterotrophic Biofloc Inoculum in Biofloc Technology enhances water quality by accelerating the consumption of organic waste and nitrogen compounds, stabilizing ammonia and nitrite levels more effectively than the Clear Water System. This method supports a sustainable aquatic environment by promoting beneficial microbial communities that reduce toxic substances and improve overall water parameters without frequent water exchange.

Biofloc Volume Index (BVI)

Biofloc Technology enhances water quality control by maintaining a high Biofloc Volume Index (BVI), which promotes the aggregation of beneficial microorganisms that improve nutrient recycling and reduce harmful ammonia levels. In contrast, Clear Water Systems rely heavily on mechanical filtration and water exchange, often resulting in lower BVI and less efficient biological nutrient removal.

Carbon to Nitrogen (C:N) Ratio Management

Biofloc Technology maintains an optimal Carbon to Nitrogen (C:N) ratio by promoting microbial growth that assimilates nitrogenous waste, effectively improving water quality and reducing the need for water exchange. In contrast, the Clear Water System relies heavily on mechanical and biological filtration to control nitrogen levels but requires frequent water replacement to maintain water quality and prevent toxic buildup.

Microbial Flocculation Dynamics

Biofloc Technology enhances water quality by promoting beneficial microbial flocculation dynamics that convert waste nutrients into microbial biomass, reducing ammonia and nitrite levels while maintaining ecological balance. In contrast, the Clear Water System relies on mechanical filtration and water exchange, which often struggles to sustain microbial populations, leading to less efficient nutrient recycling and higher water quality management costs.

autotrophic nitrifier suppression

Biofloc Technology enhances water quality control by promoting heterotrophic bacterial growth that suppresses autotrophic nitrifiers, resulting in efficient ammonia assimilation and reduced nitrite accumulation. In contrast, the Clear Water System relies on autotrophic nitrification, which often leads to slower nitrogen removal and higher risk of toxic nitrite buildup in aquaculture environments.

Sludge Retention Time (SRT)

Biofloc Technology enhances water quality control by maintaining a shorter Sludge Retention Time (SRT), effectively promoting microbial activity that decomposes organic waste and reduces toxicity. In contrast, the Clear Water System typically operates with longer SRT, requiring frequent water exchange to manage sludge accumulation and maintain optimal aquatic conditions.

Low-Salinity Biofloc Applications

Biofloc Technology enhances water quality in low-salinity aquaculture by promoting beneficial microbial communities that recycle nutrients and reduce harmful wastes, outperforming traditional Clear Water Systems that rely on frequent water exchange. Low-salinity Biofloc systems optimize nitrogen regulation and organic matter decomposition, leading to improved shrimp growth and lower environmental impact compared to Clear Water Systems.

Probiotic Enrichment in Biofloc Systems

Biofloc Technology enhances water quality control by promoting probiotic enrichment, which naturally suppresses pathogenic bacteria and improves nutrient recycling, leading to reduced ammonia and nitrite levels. In contrast, Clear Water Systems rely heavily on mechanical filtration and frequent water exchange, lacking the continuous microbial balance that probiotics provide in Biofloc Systems.

Stress-mitigating Metabolites (in clear water)

Clear Water System in aquaculture promotes the accumulation of stress-mitigating metabolites by maintaining low nutrient levels and stable water parameters, which reduces ammonia and nitrite toxicity. This environment enhances fish health and growth performance by minimizing physiological stress compared to the high organic load conditions in Biofloc Technology.

Volatile Suspended Solids (VSS) Monitoring

Biofloc Technology enhances water quality by converting organic waste into microbial protein, significantly reducing Volatile Suspended Solids (VSS) concentrations compared to Clear Water Systems that rely on external filtration and water exchange. Continuous VSS monitoring in Biofloc systems ensures optimal microbial balance and prevents detrimental toxin accumulation, promoting healthier aquatic environments and improved biomass yield.

Biofloc Technology vs Clear Water System for water quality control Infographic

agridif.com

agridif.com