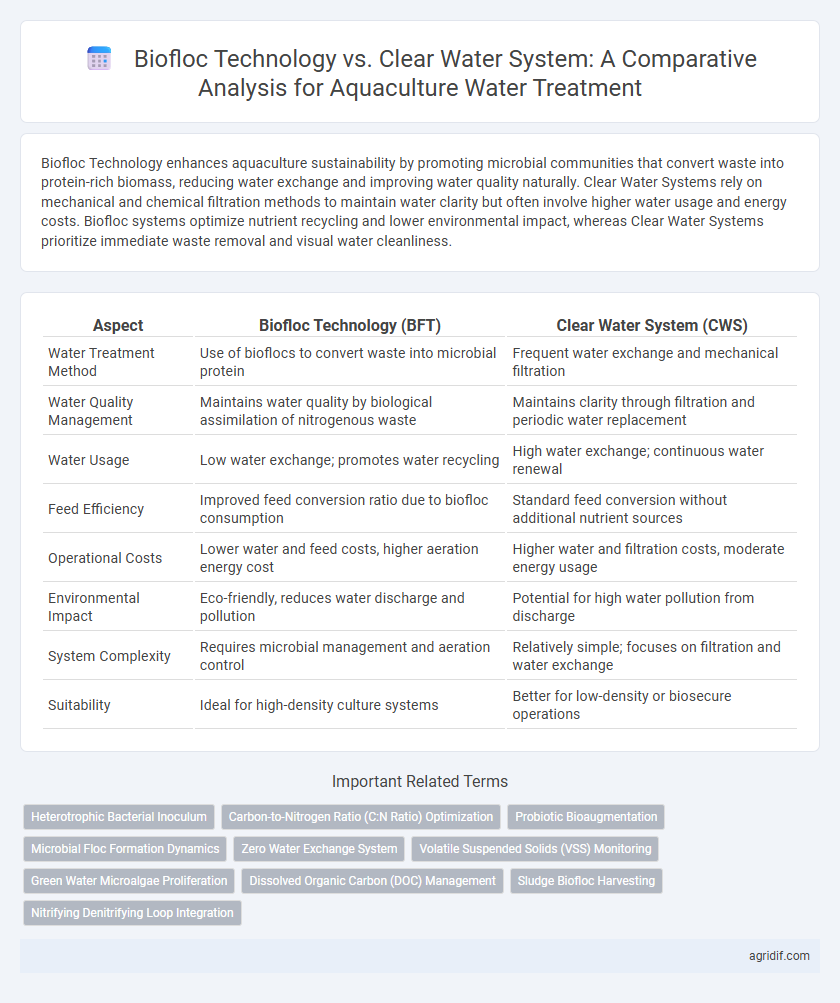

Biofloc Technology enhances aquaculture sustainability by promoting microbial communities that convert waste into protein-rich biomass, reducing water exchange and improving water quality naturally. Clear Water Systems rely on mechanical and chemical filtration methods to maintain water clarity but often involve higher water usage and energy costs. Biofloc systems optimize nutrient recycling and lower environmental impact, whereas Clear Water Systems prioritize immediate waste removal and visual water cleanliness.

Table of Comparison

| Aspect | Biofloc Technology (BFT) | Clear Water System (CWS) |

|---|---|---|

| Water Treatment Method | Use of bioflocs to convert waste into microbial protein | Frequent water exchange and mechanical filtration |

| Water Quality Management | Maintains water quality by biological assimilation of nitrogenous waste | Maintains clarity through filtration and periodic water replacement |

| Water Usage | Low water exchange; promotes water recycling | High water exchange; continuous water renewal |

| Feed Efficiency | Improved feed conversion ratio due to biofloc consumption | Standard feed conversion without additional nutrient sources |

| Operational Costs | Lower water and feed costs, higher aeration energy cost | Higher water and filtration costs, moderate energy usage |

| Environmental Impact | Eco-friendly, reduces water discharge and pollution | Potential for high water pollution from discharge |

| System Complexity | Requires microbial management and aeration control | Relatively simple; focuses on filtration and water exchange |

| Suitability | Ideal for high-density culture systems | Better for low-density or biosecure operations |

Introduction to Biofloc Technology and Clear Water Systems

Biofloc Technology (BFT) enhances aquaculture by promoting beneficial microbial communities that convert waste into protein-rich bioflocs, reducing water exchange needs while improving water quality through nitrogen recycling. Clear Water Systems (CWS) rely on physical and chemical filtration to maintain water clarity and quality, emphasizing frequent water exchange and rigorous filtration processes to manage waste and dissolved nutrients. Both systems aim to optimize water treatment but differ in approach; BFT focuses on biological waste assimilation, whereas CWS prioritize mechanical removal of contaminants.

Principle of Operation: Biofloc vs Clear Water

Biofloc technology operates by promoting the growth of heterotrophic bacteria that convert organic waste into microbial protein, maintaining water quality through continuous biofloc formation and nutrient recycling. In contrast, the clear water system relies on frequent water exchange and mechanical filtration to remove waste, requiring significant water input and external treatment. Biofloc integrates microbial communities directly within the culture environment, enhancing sustainability and reducing water usage compared to the clear water system.

Microbial Dynamics in Biofloc and Clear Water Systems

Biofloc technology enhances microbial dynamics by promoting beneficial heterotrophic bacteria that convert organic waste into microbial protein, improving water quality and nutrient recycling in aquaculture systems. In contrast, clear water systems rely heavily on mechanical and chemical filtration, resulting in lower microbial diversity and less efficient nutrient transformation. The diverse microbial communities in biofloc systems contribute to disease suppression and reduced ammonia and nitrite levels, making them more sustainable for intensive aquaculture compared to the microbial-limited environment of clear water systems.

Water Quality Management: A Comparative Analysis

Biofloc Technology enhances water quality by promoting microbial communities that convert waste into usable nutrients, reducing ammonia and nitrite levels efficiently. Clear Water Systems rely on frequent water exchanges and mechanical filtration to maintain low organic matter but often face challenges with nutrient buildup and higher operational costs. Comparative analysis shows Biofloc systems provide more stable water quality management with sustainable nitrogen recycling and lower environmental impact.

Feed Conversion and Nutrient Efficiency

Biofloc Technology significantly improves Feed Conversion Ratio (FCR) by utilizing microbial communities to convert waste into nutritious biomass, reducing feed costs and enhancing nutrient uptake. In contrast, the Clear Water System relies on frequent water exchange and filtration, often resulting in higher FCR due to nutrient losses and less feed recycling. Biofloc Systems promote superior nutrient efficiency by recycling organic matter within the system, minimizing environmental impact and optimizing growth performance in aquaculture species.

Disease Control and Health Impacts

Biofloc technology enhances disease control by promoting beneficial microbial communities that outcompete pathogens, reducing the incidence of diseases in aquaculture systems. Unlike the clear water system, which relies on frequent water exchange and chemical treatments that can stress aquatic species, biofloc maintains water quality through natural biodegradation processes, resulting in healthier stock and improved immune response. Studies show that biofloc systems significantly decrease pathogen loads and support robust fish and shrimp health, making them advantageous for sustainable disease management.

Environmental Sustainability Considerations

Biofloc Technology enhances environmental sustainability by reducing water discharge and recycling nutrients within the system, minimizing external water source dependence and lowering environmental pollution. In contrast, Clear Water Systems require frequent water exchanges, increasing effluent release and potential contamination of natural water bodies. The closed-loop nutrient cycling in Biofloc promotes resource efficiency and supports eco-friendly aquaculture practices compared to the conventional water-intensive Clear Water approach.

Economic Aspects: Cost and Profitability

Biofloc Technology reduces operational costs by recycling nutrients and minimizing water exchange, leading to savings in water, feed, and energy expenses compared to the Clear Water System. Despite higher initial setup costs, Biofloc systems improve profitability through enhanced feed conversion ratios and increased biomass yield. Clear Water Systems incur ongoing costs for water treatment and aeration, often resulting in lower profit margins due to higher maintenance and input requirements.

Suitability for Different Aquaculture Species

Biofloc Technology excels in supporting species such as tilapia, catfish, and shrimp by enhancing water quality through microbial communities that recycle nutrients and reduce harmful waste. In contrast, the Clear Water System suits species like trout and salmon, which require high oxygen levels and minimal organic load for optimal growth. Selecting the appropriate system depends on species-specific tolerance to water quality parameters, stocking density, and feed conversion efficiency.

Future Prospects and Industry Recommendations

Biofloc Technology demonstrates promising future prospects in aquaculture by enhancing water quality through microbial community management, reducing water exchange needs, and promoting sustainable nutrient recycling compared to the Clear Water System. Industry recommendations emphasize adopting biofloc for its cost-effectiveness, improved feed conversion ratios, and resilience to environmental stressors, which align with growing demands for eco-friendly and high-yield aquaculture practices. Integrating sensor technology and automation can further optimize biofloc systems, ensuring precise monitoring and control for scalable commercial applications.

Related Important Terms

Heterotrophic Bacterial Inoculum

Biofloc Technology leverages heterotrophic bacterial inoculum to rapidly convert nitrogenous wastes into microbial biomass, enhancing water quality and providing supplemental feed, while Clear Water Systems rely on physical filtration and biofiltration with autotrophic bacteria for slower nitrogen removal. The heterotrophic bacterial inoculum in Biofloc promotes efficient nutrient recycling and reduces the need for water exchange, driving sustainable aquaculture practices.

Carbon-to-Nitrogen Ratio (C:N Ratio) Optimization

Biofloc Technology optimizes the Carbon-to-Nitrogen (C:N) ratio by promoting heterotrophic bacterial growth that converts nitrogenous wastes into microbial protein, enhancing nutrient recycling and reducing water exchange needs. In contrast, Clear Water Systems rely on nitrification and physical filtration, requiring strict control of C:N ratios through external carbon addition to prevent toxic ammonia accumulation and maintain water quality.

Probiotic Bioaugmentation

Biofloc Technology enhances water quality through probiotic bioaugmentation by promoting beneficial microbial communities that degrade organic waste and nitrogenous compounds, reducing harmful pathogens and minimizing water exchange. In contrast, Clear Water Systems rely on mechanical and chemical filtration, but lack the continuous probiotic enhancement that supports natural biofloc development for efficient bioremediation and improved aquaculture sustainability.

Microbial Floc Formation Dynamics

Biofloc Technology enhances water quality through the rapid formation of microbial flocs composed of heterotrophic bacteria, algae, and protozoa that efficiently recycle nutrients and reduce toxic nitrogen compounds. In contrast, Clear Water Systems rely on mechanical filtration and frequent water exchange, which limits microbial flocculation and nutrient recycling, resulting in higher operational costs and less sustainable nutrient dynamics.

Zero Water Exchange System

Biofloc Technology enhances aquaculture productivity by utilizing microbial communities to convert waste into beneficial biomass, minimizing water usage through a zero water exchange system that maintains water quality and reduces environmental impact. In contrast, the Clear Water System relies on complete water exchanges to maintain optimal conditions, resulting in higher water consumption and greater vulnerability to water contamination.

Volatile Suspended Solids (VSS) Monitoring

Biofloc Technology significantly reduces Volatile Suspended Solids (VSS) levels through microbial assimilation, enhancing water quality and promoting sustainable aquaculture practices. In contrast, Clear Water Systems rely on mechanical filtration and water exchange, which may result in higher VSS fluctuations and increased operational costs.

Green Water Microalgae Proliferation

Biofloc Technology enhances water quality by promoting heterotrophic bacterial growth that converts organic waste into microbial proteins, reducing the need for water exchange, while Clear Water Systems rely on physical filtration and chemical treatments to maintain water clarity, often limiting natural microbial activity. Green water microalgae proliferation in Biofloc Systems supports nutrient recycling and oxygen production, fostering a balanced aquatic environment that improves shrimp and fish health compared to the typically algae-suppressed Clear Water Systems.

Dissolved Organic Carbon (DOC) Management

Biofloc Technology enhances Dissolved Organic Carbon (DOC) management by promoting microbial aggregation that converts organic waste into usable biomass, reducing DOC accumulation and improving water quality. In contrast, Clear Water Systems require frequent water exchange and filtration to control DOC levels, often resulting in higher operational costs and less efficient organic matter removal.

Sludge Biofloc Harvesting

Biofloc technology enhances aquaculture sustainability by promoting sludge biofloc harvesting, which recycles waste into microbial protein, reducing water exchange and improving feed conversion ratios. In contrast, the clear water system requires frequent water replacement to manage sludge accumulation, increasing operational costs and environmental impact.

Nitrifying Denitrifying Loop Integration

Biofloc technology enhances aquaculture sustainability by integrating nitrifying-denitrifying loops, fostering in-situ microbial communities that convert ammonia to nitrate and subsequently to nitrogen gas, reducing water exchange needs and improving water quality. In contrast, clear water systems rely heavily on mechanical filtration and external biofilters for nitrification, lacking the intrinsic denitrification processes present in biofloc systems, which limits their efficiency in nitrogen removal and increases operational costs.

Biofloc Technology vs Clear Water System for water treatment Infographic

agridif.com

agridif.com