In-pond raceway systems enhance yield optimization by increasing water circulation and oxygen levels compared to traditional pond systems, promoting faster fish growth and improved health. These systems facilitate better waste management and feed efficiency, reducing environmental impact while maximizing production. Implementing in-pond raceway technology can significantly boost aquaculture productivity by maintaining optimal water quality and reducing stocking density limitations inherent in traditional ponds.

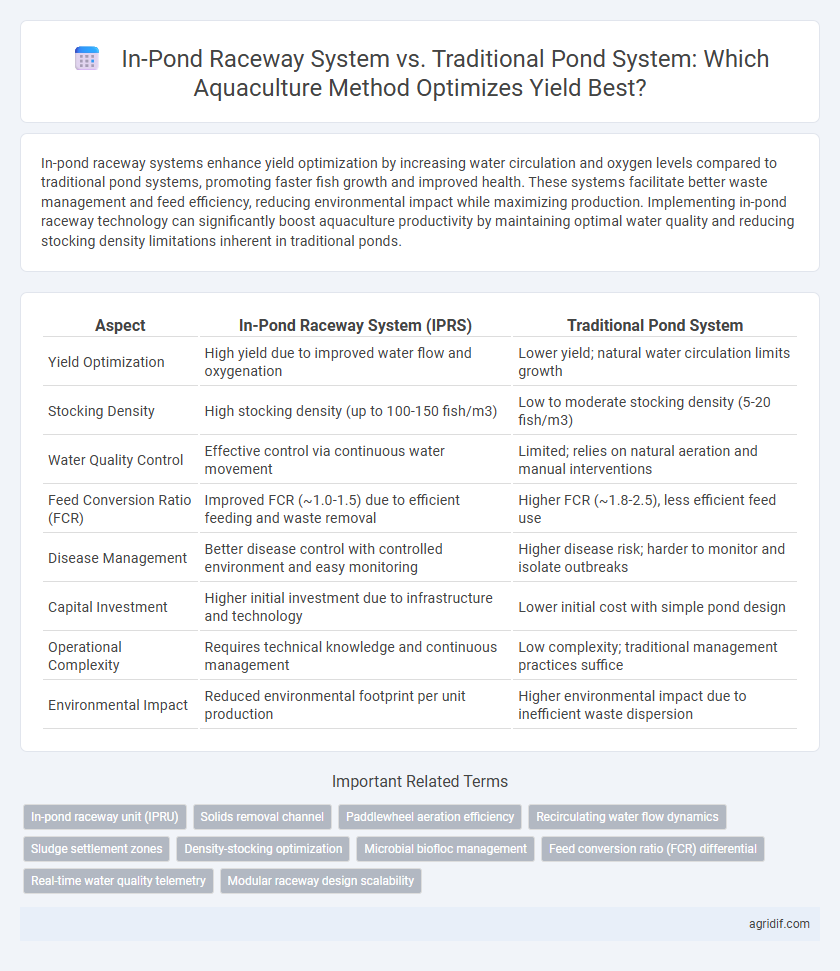

Table of Comparison

| Aspect | In-Pond Raceway System (IPRS) | Traditional Pond System |

|---|---|---|

| Yield Optimization | High yield due to improved water flow and oxygenation | Lower yield; natural water circulation limits growth |

| Stocking Density | High stocking density (up to 100-150 fish/m3) | Low to moderate stocking density (5-20 fish/m3) |

| Water Quality Control | Effective control via continuous water movement | Limited; relies on natural aeration and manual interventions |

| Feed Conversion Ratio (FCR) | Improved FCR (~1.0-1.5) due to efficient feeding and waste removal | Higher FCR (~1.8-2.5), less efficient feed use |

| Disease Management | Better disease control with controlled environment and easy monitoring | Higher disease risk; harder to monitor and isolate outbreaks |

| Capital Investment | Higher initial investment due to infrastructure and technology | Lower initial cost with simple pond design |

| Operational Complexity | Requires technical knowledge and continuous management | Low complexity; traditional management practices suffice |

| Environmental Impact | Reduced environmental footprint per unit production | Higher environmental impact due to inefficient waste dispersion |

Introduction to Aquaculture Yield Optimization

In-pond raceway systems (IPRS) offer enhanced water circulation and oxygenation compared to traditional pond systems, resulting in improved fish growth rates and higher yields. The controlled environment in IPRS allows for better feed conversion efficiency and reduced disease outbreaks, optimizing overall production. Traditional pond systems often face challenges such as oxygen depletion and uneven nutrient distribution, limiting biomass density and harvest potential.

Overview of In-pond Raceway System (IPRS)

The In-pond Raceway System (IPRS) enhances yield by enabling controlled water flow and optimized oxygen distribution within raceways integrated into traditional pond settings. This system improves feed conversion ratios and supports higher stocking densities compared to conventional pond systems, resulting in increased biomass production. Efficient waste removal and improved water quality management in IPRS contribute to healthier aquatic environments and sustainable aquaculture practices.

Understanding the Traditional Pond System

The Traditional Pond System relies on natural water bodies or earthen ponds for fish cultivation, offering simplicity and lower initial investment compared to In-pond Raceway Systems. However, this system often results in lower yield due to limited water circulation, oxygen levels, and difficulty in managing waste and fish density effectively. Understanding these limitations is crucial for optimizing production and considering advancements like raceway systems that enhance growth rates and resource efficiency.

Comparative Analysis: IPRS vs Traditional Pond System

The In-pond Raceway System (IPRS) offers higher yield optimization compared to traditional pond systems by enhancing water circulation, improving oxygen distribution, and reducing waste accumulation, which leads to better fish health and growth rates. IPRS enables controlled feeding and allows for higher stocking densities without compromising water quality, resulting in significantly increased production per unit area. In contrast, traditional pond systems tend to have lower yields due to limited water exchange and inefficient resource utilization.

Water Quality Management in Both Systems

In-pond raceway systems (IPRS) enhance water quality management by promoting continuous water circulation and improved oxygenation, which reduces ammonia and nitrite accumulation compared to traditional pond systems. Traditional pond systems often struggle with stagnant zones, leading to stratification and higher risks of harmful algal blooms and poor dissolved oxygen levels. Optimal water exchange and aeration in IPRS result in more stable physicochemical parameters, supporting higher yield and better fish health.

Feed Efficiency and Conversion Ratios

In-pond raceway systems significantly enhance feed efficiency by providing continuous water flow, which improves oxygen levels and reduces waste accumulation, leading to better fish health and faster growth rates compared to traditional pond systems. Feed conversion ratios (FCR) in in-pond raceways are optimized due to controlled feeding and reduced feed wastage, often achieving FCR values as low as 1.0 to 1.2, whereas traditional ponds typically exhibit higher FCRs around 1.5 to 2.0. These improvements contribute to higher yield per unit area and more sustainable aquaculture production.

Stocking Density and Fish Health Considerations

In-pond raceway systems enable higher stocking densities compared to traditional pond systems by facilitating continuous water flow that enhances oxygen levels and waste removal, directly supporting better fish health. The controlled environment reduces stress and disease outbreaks, promoting faster growth rates and improved survival. Optimizing stocking density within these systems maximizes yield while maintaining optimal water quality and fish welfare.

Economic Analysis: Investment and Returns

In-pond raceway systems (IPRS) demonstrate higher yield potential and faster turnover rates compared to traditional pond systems, leading to increased annual production and revenue. Although the initial investment in infrastructure and technology for IPRS is significantly higher, the enhanced feed conversion ratio and reduced mortality rates optimize operational costs and improve profitability. Economic analysis reveals that the return on investment (ROI) for IPRS surpasses traditional ponds within a shorter period, making it a cost-effective solution for sustainable aquaculture yield optimization.

Environmental Sustainability of IPRS and Traditional Ponds

The In-pond Raceway System (IPRS) enhances environmental sustainability by improving water circulation and reducing waste accumulation, which minimizes nutrient loading and decreases the risk of eutrophication compared to traditional pond systems. Traditional ponds often suffer from stagnant water and lower oxygen levels, leading to higher greenhouse gas emissions and poorer water quality. IPRS supports better feed conversion ratios and reduces the need for water exchange, contributing to resource conservation and a smaller ecological footprint in aquaculture operations.

Future Prospects and Recommendations

In-pond raceway systems offer higher yield optimization compared to traditional pond systems by enhancing water circulation and enabling better waste management, which supports sustainable aquaculture growth. Future prospects include integrating automated monitoring technologies and adopting eco-friendly feed strategies to further increase production efficiency. Recommended practices emphasize upgrading infrastructure to facilitate water quality control and incorporating selective breeding programs to maximize fish growth rates.

Related Important Terms

In-pond raceway unit (IPRU)

In-pond raceway units (IPRUs) significantly enhance aquaculture yield by improving water circulation, oxygenation, and waste removal compared to traditional pond systems, leading to healthier fish growth and higher stocking densities. IPRUs also enable better feed conversion ratios and disease control, optimizing production efficiency and sustainability in intensive aquaculture operations.

Solids removal channel

In-pond raceway systems enhance yield optimization by integrating a solids removal channel that efficiently separates and removes uneaten feed and fish waste, maintaining better water quality compared to traditional pond systems. This continuous removal of solids reduces organic load and ammonia buildup, promoting healthier fish growth and higher production rates.

Paddlewheel aeration efficiency

In-pond raceway systems with paddlewheel aeration deliver significantly higher oxygen transfer rates compared to traditional pond systems, enhancing fish growth and feed conversion efficiency. This optimized aeration reduces stratification and improves water quality, leading to yield increases of up to 30-50% in commercial aquaculture operations.

Recirculating water flow dynamics

In-pond raceway systems enhance yield optimization by utilizing continuous recirculating water flow dynamics, which improve oxygen distribution and waste removal compared to stagnant conditions in traditional pond systems. This controlled water movement in raceways promotes better fish growth rates and higher stocking densities, leading to more efficient aquaculture production.

Sludge settlement zones

In-pond raceway systems enhance yield optimization by incorporating designated sludge settlement zones that facilitate efficient waste removal, reducing toxin accumulation and improving water quality compared to traditional pond systems. This targeted sedimentation process supports healthier fish growth environments and increases overall production efficiency.

Density-stocking optimization

In-pond raceway systems enhance yield by allowing higher density-stocking optimization compared to traditional pond systems, as continuous water flow improves dissolved oxygen levels and waste removal, promoting healthier fish growth. Traditional ponds face limitations in maintaining optimal water quality at high stocking densities, resulting in lower productivity and increased disease risks.

Microbial biofloc management

In-pond raceway systems enhance yield optimization by promoting efficient microbial biofloc management through continuous water circulation and improved aeration, resulting in higher dissolved oxygen levels and reduced sludge accumulation. Traditional pond systems often face challenges in maintaining optimal biofloc balance, leading to lower feed conversion ratios and limited microbial activity, which can negatively impact fish growth and overall productivity.

Feed conversion ratio (FCR) differential

In-pond raceway systems improve yield by maintaining optimal water flow and aeration, leading to a significantly lower Feed Conversion Ratio (FCR) of approximately 1.2 compared to 1.6-2.0 in traditional pond systems. Enhanced feed efficiency in raceway systems reduces feed waste and promotes faster growth rates, maximizing production output per unit of feed input.

Real-time water quality telemetry

In-pond raceway systems (IPRS) enhance yield optimization by integrating real-time water quality telemetry, enabling continuous monitoring of parameters such as dissolved oxygen, pH, and temperature to maintain optimal aquaculture conditions. Traditional pond systems lack such precise control, often resulting in suboptimal water quality management and lower productivity.

Modular raceway design scalability

In-pond raceway systems with modular raceway design offer enhanced scalability and improved water circulation, resulting in higher yield optimization compared to traditional pond systems. This design facilitates better oxygen distribution, waste management, and stock density control, significantly increasing fish production efficiency.

In-pond raceway system vs Traditional pond system for yield optimization Infographic

agridif.com

agridif.com