Biofloc technology enhances shrimp farming by promoting beneficial microbial communities that improve water quality and reduce the need for water exchange, leading to sustainable and cost-effective production. In contrast, clear-water systems rely on frequent water replacement and filtration, which can increase operational costs and environmental impact. Biofloc offers advantages in nutrient recycling and disease control, making it a superior option for intensive shrimp aquaculture.

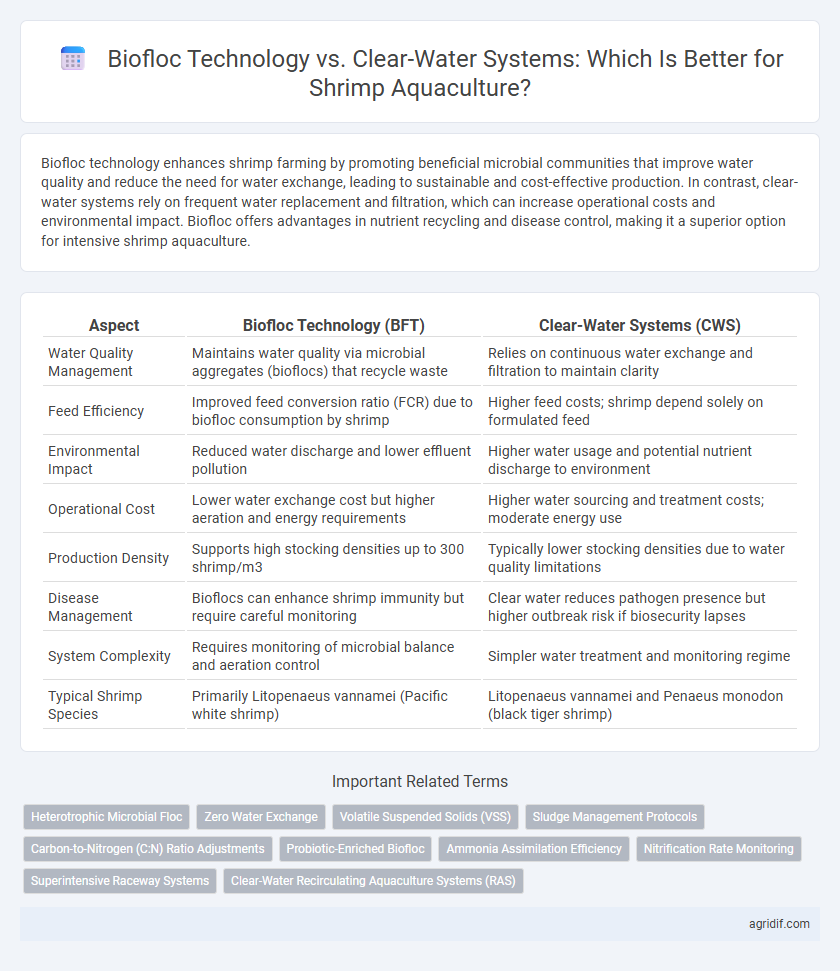

Table of Comparison

| Aspect | Biofloc Technology (BFT) | Clear-Water Systems (CWS) |

|---|---|---|

| Water Quality Management | Maintains water quality via microbial aggregates (bioflocs) that recycle waste | Relies on continuous water exchange and filtration to maintain clarity |

| Feed Efficiency | Improved feed conversion ratio (FCR) due to biofloc consumption by shrimp | Higher feed costs; shrimp depend solely on formulated feed |

| Environmental Impact | Reduced water discharge and lower effluent pollution | Higher water usage and potential nutrient discharge to environment |

| Operational Cost | Lower water exchange cost but higher aeration and energy requirements | Higher water sourcing and treatment costs; moderate energy use |

| Production Density | Supports high stocking densities up to 300 shrimp/m3 | Typically lower stocking densities due to water quality limitations |

| Disease Management | Bioflocs can enhance shrimp immunity but require careful monitoring | Clear water reduces pathogen presence but higher outbreak risk if biosecurity lapses |

| System Complexity | Requires monitoring of microbial balance and aeration control | Simpler water treatment and monitoring regime |

| Typical Shrimp Species | Primarily Litopenaeus vannamei (Pacific white shrimp) | Litopenaeus vannamei and Penaeus monodon (black tiger shrimp) |

Introduction to Shrimp Farming Systems

Biofloc technology leverages microbial communities to optimize water quality and enhance nutrient recycling, promoting a sustainable environment for shrimp growth. In contrast, clear-water systems rely on frequent water exchange and filtration to maintain low turbidity and minimize pathogen buildup. Both systems influence shrimp productivity and environmental impact, with biofloc offering benefits in waste reduction and reduced water usage compared to conventional clear-water setups.

Overview of Biofloc Technology

Biofloc Technology (BFT) enhances shrimp farming by maintaining water quality through microbial community development that converts waste into nutritious bioflocs, reducing water exchange and feed costs. This system promotes sustainable aquaculture by improving shrimp growth rates and survival compared to traditional clear-water systems, which rely on frequent water replacement and external feed inputs. BFT also supports environmental conservation by minimizing effluent discharge and optimizing resource utilization in intensive shrimp production.

Understanding Clear-Water Systems

Clear-water systems in shrimp aquaculture rely on water exchange and filtration to maintain water quality by removing suspended solids and controlling nutrient levels. This traditional method helps minimize pathogen loads and improve shrimp health but requires significant water input and infrastructure for continuous aeration and waste management. Clear-water systems offer precise environmental control but may lead to higher operational costs and environmental impact compared to biofloc technology.

Water Quality Management: Biofloc vs Clear-Water

Biofloc technology enhances water quality management by maintaining high microbial activity that converts nitrogenous wastes into beneficial proteins, reducing the need for water exchange unlike clear-water systems which rely heavily on frequent water replacement to control ammonia and nitrite levels. In biofloc systems, the microbial floc forms a natural biofilter that stabilizes water parameters, improves oxygen levels, and suppresses pathogens. Conversely, clear-water systems require rigorous mechanical filtration and chemical treatments to maintain optimal water quality, increasing operational costs and environmental impact.

Shrimp Growth and Survival Rates Comparison

Biofloc technology enhances shrimp growth by maintaining optimal water quality through microbial community management, resulting in higher feed conversion efficiency and accelerated weight gain compared to clear-water systems. Survival rates in biofloc systems consistently exceed 90%, attributable to reduced pathogen load and improved immunity, whereas clear-water systems typically show survival rates around 70-80% due to more frequent water exchange and stress exposure. This technology optimizes biochemical parameters and provides supplemental nutrition, making it superior for sustainable shrimp farming.

Feed Efficiency and Cost Implications

Biofloc Technology enhances feed efficiency in shrimp farming by recycling waste into microbial protein, reducing feed conversion ratios compared to clear-water systems. This process lowers operational costs through decreased feed consumption and less frequent water exchange requirements. In contrast, clear-water systems demand higher feed input and increased water treatment expenses, resulting in elevated overall production costs.

Disease Control and Biosecurity Measures

Biofloc Technology enhances shrimp disease control by promoting beneficial microbial communities that suppress pathogens and improve water quality, reducing the need for chemical treatments. Clear-water systems rely heavily on biosecurity measures such as water filtration, disinfection, and quarantine protocols to prevent disease introduction and spread. Comparing the two, biofloc systems offer intrinsic biological defense mechanisms, while clear-water systems depend more on external physical and chemical interventions for biosecurity.

Environmental Impact Assessment

Biofloc Technology reduces water exchange and nutrient discharge, minimizing environmental pollution compared to Clear-Water Systems that require frequent water replacement and generate higher effluent volumes. Biofloc systems enhance microbial assimilation of waste, lowering ammonia and nitrate levels, which mitigates eutrophication risks in surrounding ecosystems. Life cycle assessments indicate Biofloc offers a more sustainable approach by conserving water resources and reducing ecological footprints in shrimp aquaculture.

Economic Viability and Investment Analysis

Biofloc Technology significantly reduces feed costs by recycling waste into microbial protein, enhancing shrimp growth while maintaining water quality, which lowers operational expenses compared to Clear-Water Systems. Initial investment in biofloc systems is higher due to aeration and microbial management infrastructure, but long-term economic viability is improved through increased feed conversion efficiency and reduced water exchange costs. Clear-Water Systems require continuous water treatment and higher feed inputs, resulting in greater ongoing expenses despite lower startup costs, making biofloc the preferred option for sustainable and profitable shrimp farming.

Future Trends in Shrimp Aquaculture Systems

Biofloc technology is gaining momentum in shrimp aquaculture due to its sustainability benefits, including improved water quality management and enhanced microbial balance that supports shrimp health and reduces disease outbreaks. Future trends suggest integration of biofloc systems with precision aquaculture tools, leveraging real-time monitoring and AI to optimize nutrient cycling and minimize environmental impact. Clear-water systems may still play a role in large-scale production, but innovations in biofloc technology are positioning it as the preferred approach for eco-friendly and cost-effective shrimp farming.

Related Important Terms

Heterotrophic Microbial Floc

Biofloc technology leverages heterotrophic microbial floc to enhance shrimp growth by recycling organic waste into microbial biomass, improving water quality and reducing feed costs compared to clear-water systems. In contrast, clear-water systems require frequent water exchange and external feed inputs, lacking the beneficial microbial community inherent to biofloc systems.

Zero Water Exchange

Biofloc technology enhances shrimp production by promoting microbial growth that maintains water quality with zero water exchange, contrasting with clear-water systems that require regular water replacement to manage ammonia and other toxins. This sustainable approach reduces water consumption and disease risks while improving feed conversion ratios and shrimp yield in intensive aquaculture operations.

Volatile Suspended Solids (VSS)

Biofloc Technology (BFT) maintains higher levels of Volatile Suspended Solids (VSS), enhancing microbial activity that improves nutrient recycling and shrimp growth compared to Clear-Water Systems (CWS), which exhibit lower VSS concentrations resulting in reduced natural feed availability. Elevated VSS in BFT promotes better water quality stability and biofloc formation, crucial factors for sustainable shrimp aquaculture performance.

Sludge Management Protocols

Biofloc technology utilizes microbial communities that convert organic waste into bioavailable nutrients, significantly reducing sludge accumulation compared to traditional clear-water systems, which require frequent sludge removal and disposal to maintain water quality. Effective sludge management in biofloc systems involves controlled aeration and carbon-to-nitrogen ratio adjustments, optimizing microbial activity and minimizing environmental impact, whereas clear-water systems depend on mechanical filtration and sedimentation tanks to handle higher solid waste loads.

Carbon-to-Nitrogen (C:N) Ratio Adjustments

Biofloc technology enhances shrimp aquaculture by maintaining an optimal Carbon-to-Nitrogen (C:N) ratio, typically between 15:1 and 20:1, which promotes microbial growth that assimilates nitrogenous waste, reducing toxicity and improving water quality. In contrast, clear-water systems rely on frequent water exchange and biofiltration but often struggle to sustain stable C:N ratios, leading to higher ammonia levels and increased operational costs.

Probiotic-Enriched Biofloc

Probiotic-enriched biofloc technology enhances shrimp growth and immunity by maintaining optimal water quality through microbial aggregation, outperforming traditional clear-water systems that require frequent water exchange and chemical treatments. This sustainable approach reduces disease incidence and feed costs, leveraging beneficial bacteria to create a balanced aquatic environment ideal for high-density shrimp farming.

Ammonia Assimilation Efficiency

Biofloc technology enhances ammonia assimilation efficiency in shrimp aquaculture by promoting beneficial microbial communities that convert toxic ammonia into microbial protein, reducing the need for water exchange compared to clear-water systems. Clear-water systems rely heavily on mechanical filtration and water replacement, which are less effective in controlling ammonia levels and require higher operational costs.

Nitrification Rate Monitoring

Biofloc technology enhances nitrification rate monitoring in shrimp aquaculture by maintaining high concentrations of beneficial microbes that rapidly convert ammonia into less toxic nitrate, improving water quality and shrimp health. In contrast, clear-water systems require more frequent water exchanges and external biofilters to manage nitrification, resulting in higher operational costs and less stable microbial activity.

Superintensive Raceway Systems

Biofloc Technology in superintensive raceway systems enhances shrimp production by recycling nutrients and improving water quality through microbial community development, whereas clear-water systems require frequent water exchange and intensive management to maintain optimal conditions. Superintensive raceway systems with biofloc reduce feed costs and disease outbreaks, promoting sustainable shrimp farming with higher biomass yields compared to traditional clear-water setups.

Clear-Water Recirculating Aquaculture Systems (RAS)

Clear-water recirculating aquaculture systems (RAS) for shrimp utilize advanced filtration and biofiltration units to maintain optimal water quality by removing solid wastes and controlling nitrogenous compounds, enabling high-density shrimp farming with minimal water exchange. This system reduces environmental impact and disease risks compared to biofloc technology by providing precise control over water parameters such as dissolved oxygen, ammonia, and nitrate levels.

Biofloc Technology vs Clear-Water Systems for Shrimp Infographic

agridif.com

agridif.com