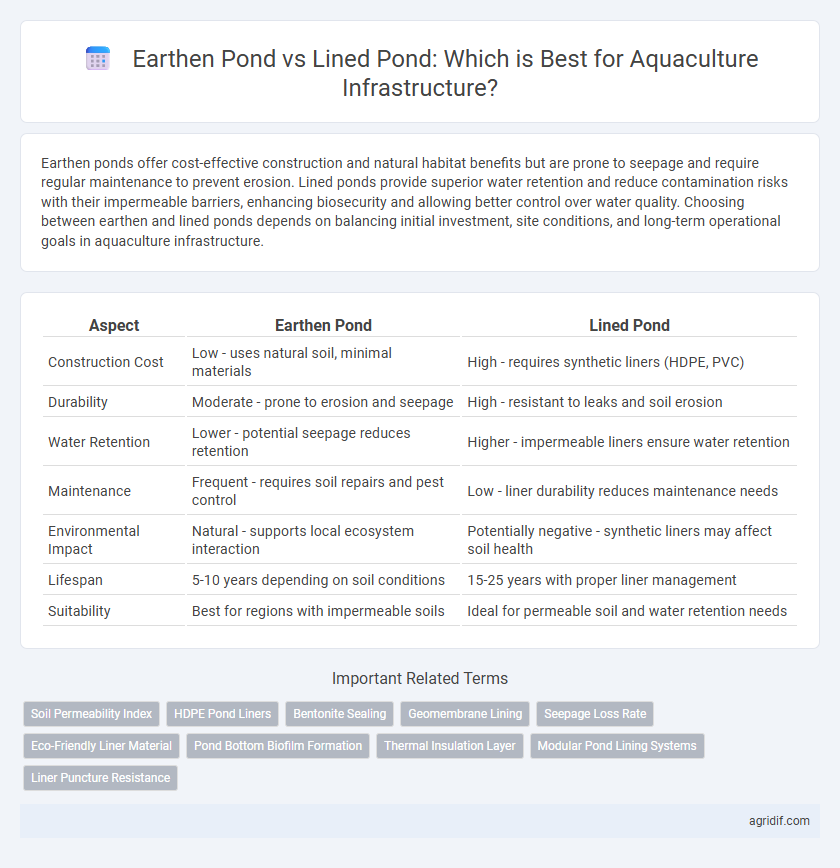

Earthen ponds offer cost-effective construction and natural habitat benefits but are prone to seepage and require regular maintenance to prevent erosion. Lined ponds provide superior water retention and reduce contamination risks with their impermeable barriers, enhancing biosecurity and allowing better control over water quality. Choosing between earthen and lined ponds depends on balancing initial investment, site conditions, and long-term operational goals in aquaculture infrastructure.

Table of Comparison

| Aspect | Earthen Pond | Lined Pond |

|---|---|---|

| Construction Cost | Low - uses natural soil, minimal materials | High - requires synthetic liners (HDPE, PVC) |

| Durability | Moderate - prone to erosion and seepage | High - resistant to leaks and soil erosion |

| Water Retention | Lower - potential seepage reduces retention | Higher - impermeable liners ensure water retention |

| Maintenance | Frequent - requires soil repairs and pest control | Low - liner durability reduces maintenance needs |

| Environmental Impact | Natural - supports local ecosystem interaction | Potentially negative - synthetic liners may affect soil health |

| Lifespan | 5-10 years depending on soil conditions | 15-25 years with proper liner management |

| Suitability | Best for regions with impermeable soils | Ideal for permeable soil and water retention needs |

Introduction to Aquaculture Pond Types

Earthen ponds, constructed by excavating natural soil, provide a cost-effective and environmentally integrated option for aquaculture infrastructure, supporting diverse species due to their natural water retention and nutrient cycling capabilities. Lined ponds, utilizing materials like HDPE or PVC liners, offer superior control over water seepage, contamination, and maintenance, making them ideal for intensive aquaculture systems requiring precise water quality management. Selection between earthen and lined ponds depends on site conditions, water availability, species cultured, and capital investment, with each type presenting unique operational advantages and challenges.

Overview of Earthen Ponds

Earthen ponds, constructed by excavating natural soil and compacting the base and sides, offer a cost-effective and environmentally sustainable option for aquaculture infrastructure. These ponds provide natural water retention and support beneficial microbial communities essential for fish health and water quality. However, earthen ponds require regular maintenance to prevent seepage and erosion, posing challenges in water management and pond longevity compared to lined ponds.

Overview of Lined Ponds

Lined ponds in aquaculture utilize synthetic or natural liners such as HDPE, PVC, or clay to prevent water seepage, ensuring optimal water retention and quality. These ponds offer enhanced control over environmental conditions, reducing contamination risks and facilitating easier management of water parameters compared to earthen ponds. The higher initial investment in lined ponds is offset by improved durability, lower maintenance costs, and increased productivity in intensive aquaculture systems.

Construction Requirements: Earthen vs Lined Ponds

Earthen pond construction demands suitable soil with proper compaction and natural waterproofing properties to minimize seepage, often requiring site-specific geotechnical evaluation. Lined ponds necessitate installing synthetic liners such as HDPE or PVC, which provide enhanced impermeability and reduce maintenance related to erosion or leakage. Selecting between earthen and lined ponds hinges on balancing initial construction costs, soil conditions, and long-term water retention efficiency crucial for sustainable aquaculture infrastructure.

Cost Comparison: Earthen Pond vs Lined Pond

Earthen ponds generally incur lower initial construction costs due to the use of natural soil and minimal materials, making them cost-effective for large-scale aquaculture projects with available land. Lined ponds, although more expensive upfront due to synthetic liners like HDPE or PVC, offer reduced water seepage and maintenance expenses, potentially lowering long-term operational costs. Selecting between earthen and lined ponds depends on factors such as soil permeability, water availability, and total budget including both capital investment and recurring costs.

Water Quality Management in Earthen and Lined Ponds

Earthen ponds rely on natural soil filtration which influences water quality management through sedimentation and nutrient cycling, often requiring regular monitoring to control turbidity and prevent eutrophication. Lined ponds use impermeable barriers like HDPE liners, significantly reducing water infiltration and contamination, thereby facilitating more consistent water quality and easier management of oxygen levels and pollutants. Effective water quality management in earthen ponds demands routine sediment removal and aeration, while lined ponds benefit from controlled water exchange and fewer external pollutant inputs.

Maintenance and Durability Considerations

Earthen ponds require regular maintenance, including sediment removal and bank repairs, to prevent erosion and water leakage, while lined ponds offer enhanced durability with reduced seepage and lower maintenance frequency. Lined ponds, often constructed with materials such as HDPE or PVC liners, provide a more stable environment by minimizing water loss and controlling seepage, which supports better water quality and longer infrastructure lifespan. The initial higher cost of lined ponds is offset by their decreased maintenance demands and increased structural reliability compared to traditional earthen ponds.

Environmental Impact: Earthen vs Lined Ponds

Earthen ponds rely on natural soil permeability, supporting groundwater recharge but posing risks of nutrient leaching and potential contamination. Lined ponds use synthetic barriers like HDPE liners to prevent seepage, reducing groundwater impact but generating non-biodegradable waste and increasing manufacturing carbon footprint. Proper environmental management requires balancing ecosystem benefits of earthen ponds with pollution control advantages and material concerns of lined ponds in sustainable aquaculture infrastructure.

Productivity and Yield Differences

Earthen ponds, constructed with natural soil, offer cost-effective infrastructure but often face challenges with water retention and seepage, leading to lower productivity and yield fluctuations. Lined ponds, using impermeable materials such as HDPE or clay liners, significantly reduce water loss and contamination risks, promoting consistent water quality and enhancing fish growth rates, thereby improving overall yield. Studies indicate that lined ponds can increase biomass production by up to 30-50% compared to earthen ponds due to better environmental control and reduced maintenance.

Choosing the Right Pond Type for Your Aquaculture Operation

Earthen ponds offer natural filtration and lower construction costs but require soil with good water retention and periodic maintenance to prevent seepage and erosion. Lined ponds, made with PVC or HDPE liners, provide higher water retention efficiency and contamination control, making them ideal for intensive aquaculture systems and areas with permeable soils. Selecting the right pond type depends on factors like budget, soil characteristics, water availability, and production goals to optimize infrastructure durability and operational efficiency.

Related Important Terms

Soil Permeability Index

Earthen ponds rely heavily on the Soil Permeability Index to determine water retention efficiency, with low permeability soils reducing seepage and maintenance costs. Lined ponds, using synthetic liners, offer consistent impermeability regardless of soil permeability, making them suitable for areas with high Soil Permeability Index values where earthen ponds would face excessive water loss.

HDPE Pond Liners

HDPE pond liners offer superior durability, chemical resistance, and impermeability compared to traditional earthen pond infrastructure, significantly reducing water loss and contamination risks in aquaculture. The high tensile strength and UV resistance of HDPE liners also ensure long-term stability and low maintenance costs, making them a preferred choice for sustainable and efficient aquaculture pond construction.

Bentonite Sealing

Earthen ponds, commonly used in aquaculture, benefit from bentonite sealing which enhances water retention by swelling to fill soil pores and cracks, minimizing seepage losses. In contrast, lined ponds use synthetic materials like HDPE liners that provide an impermeable barrier but involve higher installation costs and potential environmental concerns compared to natural bentonite-treated earthen ponds.

Geomembrane Lining

Geomembrane lining in aquaculture earthen ponds significantly enhances water retention and minimizes seepage compared to natural soil barriers, promoting better water quality and reducing environmental contamination. This engineered solution ensures durability and chemical resistance, providing an efficient, cost-effective alternative to traditional earthen pond infrastructure.

Seepage Loss Rate

Earthen ponds typically experience seepage loss rates between 0.5% and 5% per day due to soil permeability variations, whereas lined ponds with high-density polyethylene (HDPE) liners can reduce seepage losses to less than 0.1% daily. Selecting lined ponds significantly enhances water retention efficiency, lowering operational water costs and maintaining stable aquatic environments essential for productive aquaculture infrastructure.

Eco-Friendly Liner Material

Earthen ponds utilize natural soil which promotes groundwater recharge but may face water seepage issues, whereas lined ponds with eco-friendly liners made from biodegradable materials like natural rubber or recycled polymers significantly reduce seepage and improve water retention. These sustainable liners minimize environmental impact by preventing chemical leaching and supporting long-term aquaculture productivity with reduced resource depletion.

Pond Bottom Biofilm Formation

Earthen ponds naturally support robust biofilm formation on pond bottoms due to their porous soil structure, which enhances nutrient cycling and microbial diversity critical for aquaculture productivity. In contrast, lined ponds with impermeable substrates tend to limit biofilm development, potentially reducing beneficial microbial activity and affecting overall water quality management.

Thermal Insulation Layer

Earthen ponds offer natural thermal insulation due to soil's high heat capacity, stabilizing water temperature essential for aquaculture species' growth and health. Lined ponds, often constructed with polyethylene or PVC, lack inherent thermal insulation, potentially requiring supplemental measures to manage temperature fluctuations and maintain optimal aquatic environments.

Modular Pond Lining Systems

Modular pond lining systems in aquaculture offer superior durability and ease of installation compared to traditional earthen ponds, significantly reducing seepage and maintenance costs. These systems enhance water retention and biosecurity, promoting sustainable fish farming with minimal environmental impact.

Liner Puncture Resistance

Lined ponds offer superior puncture resistance compared to earthen ponds, significantly reducing the risk of leaks and structural failures in aquaculture infrastructure. High-density polyethylene (HDPE) liners provide enhanced durability against sharp objects and environmental stresses, ensuring longer operational lifespan and minimizing maintenance costs.

Earthen Pond vs Lined Pond for infrastructure Infographic

agridif.com

agridif.com