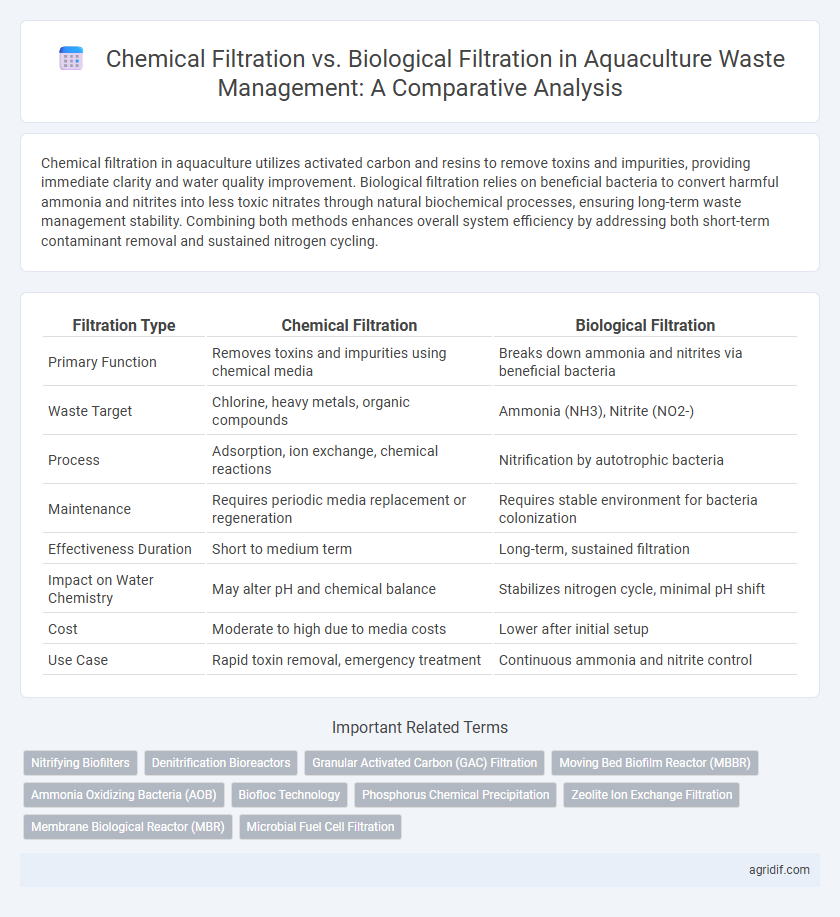

Chemical filtration in aquaculture utilizes activated carbon and resins to remove toxins and impurities, providing immediate clarity and water quality improvement. Biological filtration relies on beneficial bacteria to convert harmful ammonia and nitrites into less toxic nitrates through natural biochemical processes, ensuring long-term waste management stability. Combining both methods enhances overall system efficiency by addressing both short-term contaminant removal and sustained nitrogen cycling.

Table of Comparison

| Filtration Type | Chemical Filtration | Biological Filtration |

|---|---|---|

| Primary Function | Removes toxins and impurities using chemical media | Breaks down ammonia and nitrites via beneficial bacteria |

| Waste Target | Chlorine, heavy metals, organic compounds | Ammonia (NH3), Nitrite (NO2-) |

| Process | Adsorption, ion exchange, chemical reactions | Nitrification by autotrophic bacteria |

| Maintenance | Requires periodic media replacement or regeneration | Requires stable environment for bacteria colonization |

| Effectiveness Duration | Short to medium term | Long-term, sustained filtration |

| Impact on Water Chemistry | May alter pH and chemical balance | Stabilizes nitrogen cycle, minimal pH shift |

| Cost | Moderate to high due to media costs | Lower after initial setup |

| Use Case | Rapid toxin removal, emergency treatment | Continuous ammonia and nitrite control |

Introduction to Waste Management in Aquaculture

Chemical filtration in aquaculture targets the removal of dissolved wastes and harmful chemicals through processes like activated carbon absorption and ion exchange, effectively purifying water to maintain optimal fish health. Biological filtration employs beneficial bacteria to convert toxic ammonia and nitrite, generated from fish waste, into less harmful nitrate via nitrification, supporting a sustainable aquatic environment. Effective waste management integrates both filtration methods to ensure water quality, promote fish growth, and reduce environmental impact in aquaculture systems.

Understanding Chemical Filtration in Aquaculture Systems

Chemical filtration in aquaculture systems utilizes activated carbon, ion exchange resins, or other media to remove toxins such as ammonia, nitrites, and dissolved organic compounds from the water. This method effectively controls water quality by adsorbing harmful chemicals and contaminants, preventing their accumulation and promoting a healthier aquatic environment. Unlike biological filtration, chemical filtration provides rapid pollutant removal but requires regular media replacement to maintain efficiency.

Principles of Biological Filtration for Aquatic Environments

Biological filtration in aquaculture relies on nitrifying bacteria to convert toxic ammonia and nitrite into less harmful nitrate, maintaining water quality and supporting aquatic life health. This process takes place in biofilters with substrates that provide surface area for beneficial microbial colonization, optimizing waste breakdown and nutrient cycling. Effective biological filtration enhances system stability and reduces chemical dependency compared to chemical filtration methods.

Key Differences Between Chemical and Biological Filtration

Chemical filtration in aquaculture uses activated carbon or resins to remove toxins, impurities, and dissolved organic compounds, offering rapid water clarification and toxin removal. Biological filtration relies on beneficial nitrifying bacteria to convert harmful ammonia and nitrites into less toxic nitrates, promoting long-term water stability and nitrogen cycle balance. The key differences lie in chemical filtration's immediate pollutant adsorption versus biological filtration's ongoing biochemical waste transformation.

Efficiency of Chemical Filtration in Removing Contaminants

Chemical filtration efficiently removes dissolved contaminants such as ammonia, nitrites, and heavy metals from aquaculture systems by using activated carbon or ion exchange resins. This method rapidly reduces toxins, improving water clarity and quality, which is critical for maintaining fish health and preventing stress. However, chemical filtration alone does not break down organic waste and should be integrated with biological filtration for comprehensive waste management.

Role of Biological Filtration in Nitrification and Water Quality

Biological filtration plays a crucial role in nitrification by converting toxic ammonia into less harmful nitrate through the activity of nitrifying bacteria such as Nitrosomonas and Nitrobacter. This process significantly improves water quality in aquaculture systems by maintaining low ammonia levels, reducing fish stress, and preventing toxic buildup. In comparison to chemical filtration, biological filtration offers a sustainable and efficient method to stabilize nitrogenous waste and support healthy aquatic environments.

Environmental Impact of Chemical vs Biological Filtration

Chemical filtration in aquaculture uses activated carbon and resins to remove toxins rapidly but can generate hazardous waste requiring proper disposal to prevent environmental contamination. Biological filtration relies on nitrifying bacteria to convert harmful ammonia and nitrites into less toxic nitrates, promoting a natural and sustainable waste management process with minimal ecological disruption. The environmental impact favors biological filtration due to lower chemical use and enhanced ecosystem compatibility, supporting healthier aquatic environments.

Cost Analysis: Chemical vs Biological Filtration Solutions

Chemical filtration systems generally involve higher operational costs due to the frequent replacement of activated carbon, resins, or chemicals required to remove toxins and impurities from aquaculture water. In contrast, biological filtration utilizes beneficial bacteria to naturally break down waste products, resulting in lower ongoing expenses but potentially higher initial setup costs for biofilter media and system design. Evaluating total cost of ownership should consider long-term maintenance, labor, and system efficiency to optimize waste management in aquaculture facilities.

Practical Considerations for Filtration Selection in Aquaculture

Chemical filtration in aquaculture effectively removes dissolved organic compounds and toxins, providing rapid water quality improvement, while biological filtration supports beneficial bacteria that convert harmful ammonia and nitrite into less toxic nitrate, ensuring long-term stability. Practical considerations for filtration selection include system size, stocking density, and specific waste load characteristics, as well as maintenance capability and cost-efficiency. Combining both filtration types often yields optimal waste management, balancing immediate contaminant removal with sustainable nutrient cycling.

Future Trends in Aquaculture Waste Filtration Technologies

Future trends in aquaculture waste filtration technologies emphasize the integration of advanced chemical filtration media with enhanced biological filtration systems to maximize pollutant removal efficiency. Innovations such as bioengineered enzyme filters and nanomaterial-based adsorbents aim to accelerate the breakdown of nitrogenous wastes while maintaining water quality. Increasing adoption of hybrid filtration units combining both chemical and biological processes is set to improve sustainability and reduce environmental impact in large-scale aquaculture operations.

Related Important Terms

Nitrifying Biofilters

Nitrifying biofilters play a crucial role in biological filtration by converting toxic ammonia into less harmful nitrate through the activity of nitrifying bacteria, significantly enhancing water quality in aquaculture systems. Unlike chemical filtration that relies on media to adsorb waste, biological filtration supports sustainable nitrogen cycling, reducing ammonia accumulation and promoting healthier aquatic environments.

Denitrification Bioreactors

Denitrification bioreactors in aquaculture enhance waste management by converting harmful nitrates into nitrogen gas, outperforming chemical filtration methods that primarily remove toxins without addressing nitrate accumulation. Biological filtration fosters sustainable water quality by harnessing microbial communities to detoxify ammonia and nitrites, while denitrification bioreactors specifically target nitrate reduction, crucial for maintaining optimal aquatic health and minimizing environmental impact.

Granular Activated Carbon (GAC) Filtration

Granular Activated Carbon (GAC) filtration excels in chemical filtration by adsorbing dissolved organic compounds, toxins, and contaminants, effectively improving water quality in aquaculture systems. Unlike biological filtration that relies on microbial breakdown of ammonia and nitrites, GAC filtration targets chemical pollutants, enhancing waste management by removing harmful substances that biological processes cannot degrade.

Moving Bed Biofilm Reactor (MBBR)

Chemical filtration in aquaculture primarily targets the removal of dissolved wastes and toxins using activated carbon or chemical resins, while biological filtration leverages microbial biofilms to convert harmful ammonia into less toxic nitrates. The Moving Bed Biofilm Reactor (MBBR) enhances biological filtration efficiency by providing a large surface area for biofilm growth on moving carriers, ensuring robust ammonia oxidation and improved water quality in aquaculture systems.

Ammonia Oxidizing Bacteria (AOB)

Chemical filtration effectively removes physical impurities and toxins from aquaculture water but cannot biologically convert harmful ammonia compounds, a task performed by Ammonia Oxidizing Bacteria (AOB) during biological filtration. AOB play a crucial role in waste management by oxidizing ammonia into nitrite, significantly reducing toxicity and promoting a healthier aquatic environment.

Biofloc Technology

Biofloc Technology integrates biological filtration by promoting beneficial microbial communities that convert ammonia and organic waste into microbial protein, enhancing water quality and providing a natural feed source. Compared to traditional chemical filtration that relies on synthetic resins or chemicals to remove waste, biofloc's microbial-driven process ensures sustainable nutrient recycling and reduces the need for water exchange in aquaculture systems.

Phosphorus Chemical Precipitation

Phosphorus chemical precipitation in aquaculture effectively removes phosphorus from wastewater, reducing eutrophication risks by forming insoluble phosphate compounds that settle out of the system. Unlike biological filtration, which relies on microbial assimilation and transformation, chemical filtration provides rapid phosphorus removal, enhancing overall waste management efficiency in intensive aquaculture setups.

Zeolite Ion Exchange Filtration

Zeolite ion exchange filtration excels in aquaculture waste management by selectively removing ammonia and heavy metals, enhancing water quality more efficiently than traditional biological filtration. Its high cation exchange capacity allows rapid detoxification, preventing toxic buildup and promoting a healthier aquatic environment.

Membrane Biological Reactor (MBR)

Membrane Biological Reactor (MBR) technology in aquaculture combines biological filtration with membrane filtration to efficiently remove organic waste and dissolved solids, enhancing water quality and reducing ammonia and nitrite levels. MBR systems outperform traditional chemical filtration by promoting beneficial microbial activity for biodegradation while physically retaining suspended solids, resulting in superior waste management and sustainability in recirculating aquaculture systems (RAS).

Microbial Fuel Cell Filtration

Microbial Fuel Cell (MFC) filtration integrates biological filtration by harnessing electrogenic bacteria to convert organic waste into electricity, enhancing waste management efficiency in aquaculture systems. This method surpasses traditional chemical filtration by reducing chemical additives while promoting sustainable nutrient cycling and toxin removal through microbial metabolism.

Chemical Filtration vs Biological Filtration for waste management Infographic

agridif.com

agridif.com