Extensive aquaculture for shrimp production relies on natural water bodies and minimal input, promoting sustainable growth with lower operational costs but slower yield rates. Intensive aquaculture involves high stocking densities, advanced feeding, and water quality management to maximize shrimp output within limited space, though it demands significant investment and carries higher risks of disease. Balancing ecological impact and productivity is crucial when choosing the appropriate system between extensive and intensive shrimp farming.

Table of Comparison

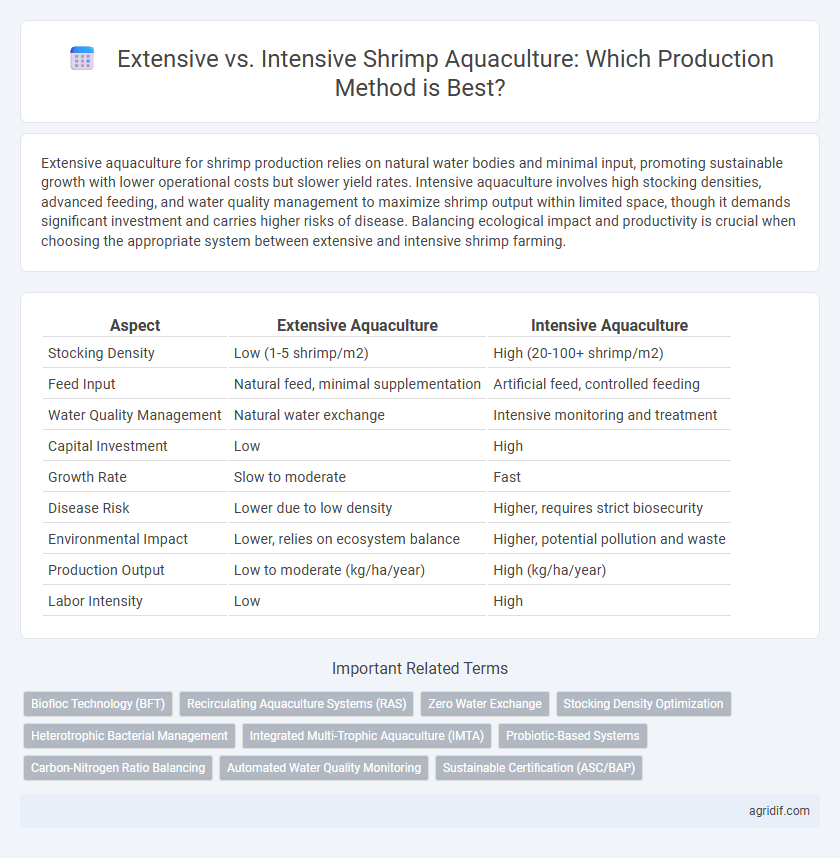

| Aspect | Extensive Aquaculture | Intensive Aquaculture |

|---|---|---|

| Stocking Density | Low (1-5 shrimp/m2) | High (20-100+ shrimp/m2) |

| Feed Input | Natural feed, minimal supplementation | Artificial feed, controlled feeding |

| Water Quality Management | Natural water exchange | Intensive monitoring and treatment |

| Capital Investment | Low | High |

| Growth Rate | Slow to moderate | Fast |

| Disease Risk | Lower due to low density | Higher, requires strict biosecurity |

| Environmental Impact | Lower, relies on ecosystem balance | Higher, potential pollution and waste |

| Production Output | Low to moderate (kg/ha/year) | High (kg/ha/year) |

| Labor Intensity | Low | High |

Overview of Extensive and Intensive Shrimp Aquaculture

Extensive shrimp aquaculture relies on natural water bodies and low stocking densities, minimizing feed input and operational costs, but often results in lower yields and longer production cycles. Intensive shrimp aquaculture utilizes controlled environments with high stocking densities, formulated feeds, and advanced water management to maximize growth rates and productivity, albeit with higher capital investment and environmental management needs. Balancing these methods depends on technological capacity, environmental sustainability, and market demand for shrimp production.

Key Differences Between Extensive and Intensive Methods

Extensive aquaculture for shrimp production relies on natural water bodies with minimal feed input and low stocking densities, resulting in lower yields but reduced environmental impact. Intensive aquaculture employs high stocking densities, formulated feeds, and controlled water quality to maximize production, often necessitating advanced technology and higher operational costs. Key differences include feed management, environmental control, production scale, and economic investment, with extensive systems favoring sustainability and intensive systems prioritizing yield efficiency.

Input Requirements for Extensive vs Intensive Shrimp Farming

Extensive shrimp farming requires low input, relying on natural feed and environmental conditions, with minimal labor and infrastructure costs. Intensive shrimp farming demands high input, including formulated feed, aeration, water quality management, and advanced monitoring systems to achieve higher productivity. The discrepancy in feed conversion ratios and stocking densities highlights the significant resource differences between extensive and intensive shrimp aquaculture.

Environmental Impact Comparison: Extensive vs Intensive Systems

Extensive aquaculture for shrimp production relies on natural water bodies and low stocking densities, resulting in minimal environmental disruption and enhanced ecosystem balance. Intensive aquaculture involves high stocking densities and controlled feeding, which often leads to increased nutrient loading, waste accumulation, and potential habitat degradation. Comparing both systems, extensive aquaculture presents a lower ecological footprint, while intensive methods offer higher yields but require rigorous environmental management to mitigate adverse effects.

Production Yields: Evaluating Output in Both Approaches

Intensive aquaculture yields significantly higher shrimp production per unit area, often reaching up to 10,000 kg per hectare annually, compared to extensive systems that typically produce between 500 to 1,000 kg per hectare. Extensive aquaculture relies on natural productivity with minimal input, resulting in lower but more sustainable output. Intensive systems demand high feed input, aeration, and management, maximizing yield but increasing operational costs and environmental impact.

Disease Management in Extensive and Intensive Shrimp Culture

Extensive aquaculture for shrimp production relies on natural water exchange and low stocking densities, reducing disease outbreaks through enhanced environmental balance but limiting control over pathogens. Intensive aquaculture employs high stocking densities and controlled systems, necessitating rigorous disease management practices such as biosecurity protocols, water quality monitoring, and prophylactic treatments to prevent rapid disease transmission. Effective disease management in intensive shrimp culture includes regular health assessments, use of pathogen-free larvae, and integrated pest management to sustain high productivity and minimize losses.

Economic Viability: Cost Analysis and Profitability

Extensive aquaculture for shrimp production involves lower operational costs due to minimal feed and infrastructure requirements but yields lower shrimp output, impacting overall profitability. Intensive aquaculture demands significant investment in feed, aeration, and system maintenance, resulting in higher production levels and faster growth rates, which can enhance economic viability when market prices are favorable. Careful cost analysis reveals that intensive systems achieve greater profit margins in high-demand conditions, while extensive systems are more sustainable with reduced financial risk in fluctuating markets.

Suitability for Small-Scale and Large-Scale Farmers

Extensive aquaculture for shrimp production is highly suitable for small-scale farmers due to its low input costs, reliance on natural productivity, and minimal technical expertise required. Intensive aquaculture, characterized by high stocking densities, advanced water management, and greater capital investment, aligns better with large-scale farmers seeking higher yields and controlled environments. Small-scale operations benefit from extensive systems' sustainability and simplicity, while commercial enterprises maximize output and efficiency through intensive methods.

Technological Innovations in Shrimp Aquaculture Systems

Technological innovations in shrimp aquaculture systems have significantly advanced both extensive and intensive farming methods by improving water quality management, disease control, and feed efficiency. Extensive aquaculture benefits from satellite monitoring and biofloc technology to optimize natural pond ecosystems with minimal intervention. Intensive aquaculture relies on automated feeding systems, controlled recirculating aquaculture systems (RAS), and advanced sensor technology to maximize shrimp growth rates and production density.

Sustainability and Future Trends in Shrimp Farming Practices

Extensive aquaculture for shrimp production relies on natural water bodies with minimal inputs, promoting ecological balance and reducing environmental impact, which supports long-term sustainability. Intensive aquaculture utilizes high stocking densities and advanced technology to maximize yield but demands careful management of waste and feed to mitigate pollution and disease risks. Future trends emphasize integrated multi-trophic systems and biotechnology enhancements to increase productivity while minimizing ecological footprints, ensuring sustainable shrimp farming growth.

Related Important Terms

Biofloc Technology (BFT)

Extensive aquaculture relies on natural productivity in large pond systems with low stocking densities, resulting in slower shrimp growth and lower yields, whereas intensive aquaculture uses high stocking densities supported by advanced systems like Biofloc Technology (BFT), which enhances water quality and provides supplemental nutrition through microbial communities, significantly improving shrimp growth rates and feed conversion ratios. Biofloc Technology optimizes intensive shrimp farming by reducing water exchange, minimizing environmental impact, and promoting sustainable production with higher biomass output.

Recirculating Aquaculture Systems (RAS)

Extensive aquaculture relies on natural water bodies with minimal human intervention and low stocking densities, whereas intensive aquaculture employs high stocking densities and controlled environments such as Recirculating Aquaculture Systems (RAS) for shrimp production. RAS technology enhances biosecurity, optimizes water reuse, and supports higher shrimp yields by maintaining precise water quality parameters and reducing environmental impact compared to traditional extensive methods.

Zero Water Exchange

Extensive aquaculture for shrimp production relies on natural water exchange with minimal management, leading to lower environmental impact but reduced yield per hectare, whereas intensive aquaculture employs high stocking densities and controlled zero water exchange systems to maximize production and minimize water usage. Zero water exchange techniques enhance biosecurity and water quality through advanced filtration and biofloc technology, supporting sustainable, high-density shrimp farming in intensive setups.

Stocking Density Optimization

Extensive aquaculture for shrimp production utilizes low stocking densities, typically ranging from 2 to 5 shrimp per square meter, promoting natural growth with minimal environmental control and reduced operational costs. Intensive aquaculture employs high stocking densities of 100 to 300 shrimp per square meter, requiring advanced water quality management and aeration systems to optimize growth rates and maximize yield within controlled environments.

Heterotrophic Bacterial Management

Extensive aquaculture for shrimp production relies on natural bacterial populations and organic matter decomposition, resulting in lower stocking densities and minimal water exchange, whereas intensive aquaculture employs controlled heterotrophic bacterial management through biofloc technology to optimize water quality and support higher shrimp densities. Effective manipulation of microbial communities in intensive systems enhances nutrient recycling and disease control, crucial for maximizing shrimp growth and survival rates.

Integrated Multi-Trophic Aquaculture (IMTA)

Extensive aquaculture for shrimp production relies on natural productivity with low stocking densities and minimal inputs, whereas intensive aquaculture uses high stocking densities and substantial feed and management to maximize yield. Integrated Multi-Trophic Aquaculture (IMTA) optimizes resource use by combining shrimp with species like seaweed and filter feeders, enhancing water quality and sustainability in both extensive and intensive systems.

Probiotic-Based Systems

Probiotic-based systems in extensive aquaculture enhance shrimp health through natural microbial balance, promoting sustainable, low-input farming methods with minimal environmental impact. In contrast, intensive aquaculture leverages probiotics to boost shrimp growth rates and disease resistance within high-density environments, optimizing production efficiency but requiring careful management to prevent water quality degradation.

Carbon-Nitrogen Ratio Balancing

Extensive aquaculture relies on natural productivity and lower stocking densities, resulting in a fluctuating carbon-nitrogen ratio that can limit shrimp growth but reduces environmental impact. Intensive aquaculture employs controlled feeding and waste management to maintain an optimized carbon-nitrogen ratio, enhancing shrimp yield and minimizing nitrogenous waste accumulation in the system.

Automated Water Quality Monitoring

Automated water quality monitoring in intensive shrimp aquaculture enhances real-time control of parameters like dissolved oxygen, pH, and ammonia, significantly reducing disease outbreaks and boosting shrimp yields. Extensive aquaculture relies on natural water exchange and less frequent monitoring, resulting in lower operational costs but increased vulnerability to environmental fluctuations.

Sustainable Certification (ASC/BAP)

Extensive aquaculture for shrimp production relies on low stocking densities and natural productivity, promoting ecosystem balance and earning sustainable certifications such as ASC (Aquaculture Stewardship Council) and BAP (Best Aquaculture Practices) due to reduced environmental impact. In contrast, intensive aquaculture uses high stocking densities and controlled feeding, requiring strict management protocols and resource inputs to meet ASC/BAP standards focused on minimizing pollution, disease, and resource depletion.

Extensive Aquaculture vs Intensive Aquaculture for shrimp production Infographic

agridif.com

agridif.com