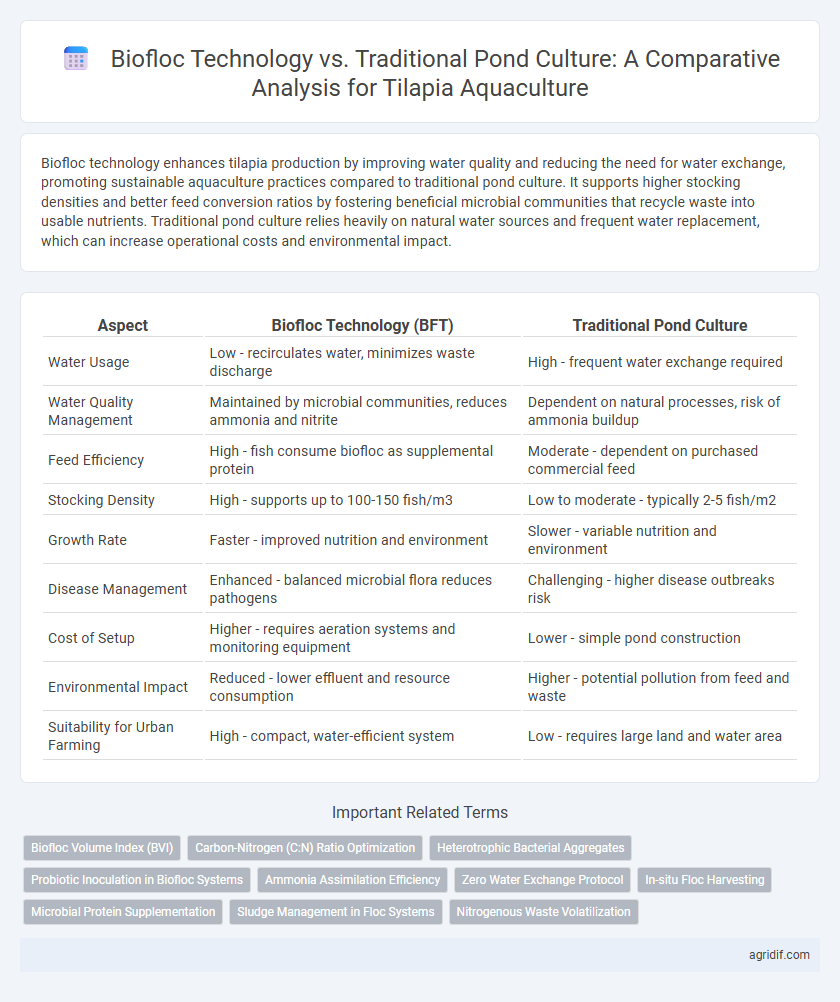

Biofloc technology enhances tilapia production by improving water quality and reducing the need for water exchange, promoting sustainable aquaculture practices compared to traditional pond culture. It supports higher stocking densities and better feed conversion ratios by fostering beneficial microbial communities that recycle waste into usable nutrients. Traditional pond culture relies heavily on natural water sources and frequent water replacement, which can increase operational costs and environmental impact.

Table of Comparison

| Aspect | Biofloc Technology (BFT) | Traditional Pond Culture |

|---|---|---|

| Water Usage | Low - recirculates water, minimizes waste discharge | High - frequent water exchange required |

| Water Quality Management | Maintained by microbial communities, reduces ammonia and nitrite | Dependent on natural processes, risk of ammonia buildup |

| Feed Efficiency | High - fish consume biofloc as supplemental protein | Moderate - dependent on purchased commercial feed |

| Stocking Density | High - supports up to 100-150 fish/m3 | Low to moderate - typically 2-5 fish/m2 |

| Growth Rate | Faster - improved nutrition and environment | Slower - variable nutrition and environment |

| Disease Management | Enhanced - balanced microbial flora reduces pathogens | Challenging - higher disease outbreaks risk |

| Cost of Setup | Higher - requires aeration systems and monitoring equipment | Lower - simple pond construction |

| Environmental Impact | Reduced - lower effluent and resource consumption | Higher - potential pollution from feed and waste |

| Suitability for Urban Farming | High - compact, water-efficient system | Low - requires large land and water area |

Introduction to Tilapia Farming: Biofloc vs Traditional Pond

Tilapia farming using Biofloc Technology (BFT) enhances water quality by promoting beneficial microbial communities that recycle waste into feed, leading to higher stocking densities and improved growth rates compared to traditional pond culture. Traditional pond systems rely on natural water exchange and sedimentation to maintain water quality, often resulting in lower productivity and more frequent water management challenges. Biofloc's integrated approach reduces feed costs and environmental impact while boosting tilapia survival and overall yield, making it a sustainable alternative to conventional pond aquaculture.

Overview of Biofloc Technology in Aquaculture

Biofloc Technology in aquaculture enhances water quality and reduces operational costs by utilizing microbial communities to convert waste nutrients into protein-rich bioflocs, which serve as supplementary feed for tilapia. This innovative system promotes sustainable tilapia farming by improving growth rates and feed conversion efficiency compared to traditional pond culture, which relies heavily on external feed inputs and frequent water exchange. Biofloc's integrated approach supports higher stocking densities and lowers environmental impact, making it a promising advancement in sustainable aquaculture practices.

Traditional Pond Culture Methods for Tilapia

Traditional pond culture methods for tilapia involve raising fish in earthen ponds with natural water exchange and reliance on external feed inputs, such as formulated feeds and supplemental fertilizers to promote plankton growth. This approach benefits from simplicity and low initial investment but often faces challenges like water quality fluctuations, disease outbreaks, and lower feed conversion efficiency. Despite these limitations, traditional pond culture remains widely practiced due to its adaptability to local conditions and established management practices in tilapia farming.

Comparative Water Quality Management

Biofloc Technology maintains superior water quality in tilapia farming by promoting beneficial microbial communities that degrade organic waste, reducing ammonia and nitrite levels compared to Traditional Pond Culture. The biofloc system enhances dissolved oxygen and stabilizes pH, minimizing toxic substance accumulation without frequent water exchange. In contrast, Traditional Pond Culture relies heavily on water renewal and aeration to manage water quality, often facing challenges with nutrient buildup and fluctuating parameters.

Nutrient Utilization and Feed Efficiency

Biofloc Technology enhances nutrient utilization in tilapia farming by recycling waste into microbial biomass, reducing the need for external feed inputs and improving feed conversion ratios compared to traditional pond culture. This system promotes efficient nitrogen cycling and minimizes water exchange, leading to lower environmental impact and better growth performance. Traditional pond culture typically requires higher feed amounts and results in lower nutrient retention due to sedimentation and less microbial activity.

Disease Management and Fish Health

Biofloc Technology significantly enhances disease management in tilapia culture by maintaining better water quality and promoting beneficial microbial communities that inhibit pathogen growth, compared to Traditional Pond Culture. The biofloc system reduces reliance on antibiotics and chemicals, resulting in healthier fish with stronger immune responses and higher survival rates. In contrast, Traditional Pond Culture often faces challenges with water quality fluctuations and higher incidences of bacterial and parasitic infections, increasing fish stress and mortality.

Environmental Sustainability Considerations

Biofloc technology significantly enhances environmental sustainability in tilapia farming by reducing water exchange needs and promoting nutrient recycling, which minimizes effluent discharge and eutrophication risks. In contrast, traditional pond culture typically requires frequent water replacement and generates higher nutrient waste, leading to greater environmental impact. The closed-loop system of biofloc also improves oxygen levels and supports beneficial microbial communities, fostering a more balanced aquatic ecosystem.

Economic Analysis: Biofloc vs Pond Culture

Biofloc technology reduces feed costs by up to 30% compared to traditional pond culture due to enhanced natural feed availability and improved nutrient recycling. Economic analysis shows higher production efficiency and better water use in biofloc systems, resulting in increased tilapia yield per unit area and reduced operational expenses. While initial setup costs for biofloc may be higher, rapid growth rates and lower mortality translate to greater overall profitability.

Production Yields and Growth Rates

Biofloc Technology significantly enhances tilapia production yields by promoting beneficial microbial communities that improve water quality and nutrient recycling, resulting in higher stocking densities and reduced feed conversion ratios compared to Traditional Pond Culture. Growth rates in biofloc systems are notably faster due to the continuous availability of biofloc as a natural protein source, optimizing feed efficiency and promoting robust fish health. Studies demonstrate that tilapia in biofloc environments achieve up to 30-40% higher weight gain and increased survival rates, making it a more sustainable and productive aquaculture method.

Future Prospects and Adoption Challenges

Biofloc Technology offers enhanced water quality management and nutrient recycling, making it a sustainable alternative to Traditional Pond Culture for tilapia farming. Future prospects include increased yield efficiency and disease resistance, driven by microbial community optimization within biofloc systems. Adoption challenges remain in initial investment costs, technical expertise requirements, and scalability constraints for small-scale producers.

Related Important Terms

Biofloc Volume Index (BVI)

Biofloc Technology significantly enhances tilapia production by maintaining a higher Biofloc Volume Index (BVI), which promotes microbial growth essential for water quality and nutrient recycling. In contrast, traditional pond culture often exhibits lower BVI levels, resulting in less efficient nutrient use and potentially higher feed costs.

Carbon-Nitrogen (C:N) Ratio Optimization

Biofloc technology enhances tilapia production by optimizing the Carbon-Nitrogen (C:N) ratio, promoting microbial growth that assimilates nitrogenous waste, thus maintaining water quality and reducing the need for water exchange. Traditional pond culture lacks precise C:N ratio control, often resulting in nitrogen accumulation and suboptimal water conditions that hinder tilapia growth and health.

Heterotrophic Bacterial Aggregates

Biofloc technology enhances tilapia production by promoting heterotrophic bacterial aggregates that improve water quality and supply natural microbial protein, leading to higher growth rates and reduced feed costs compared to traditional pond culture. Traditional pond culture relies on natural productivity with limited microbial management, often resulting in lower microbial biomass and potential water quality issues affecting tilapia health and yield.

Probiotic Inoculation in Biofloc Systems

Biofloc Technology enhances tilapia growth by utilizing probiotic inoculation to maintain water quality and promote beneficial microbial communities, reducing disease outbreaks common in traditional pond culture. This method increases feed efficiency and sustainable biomass production by recycling nutrients, contrasting with the limited microbial control and higher environmental impact seen in conventional pond systems.

Ammonia Assimilation Efficiency

Biofloc Technology significantly enhances ammonia assimilation efficiency in tilapia cultivation by promoting microbial biomass that converts toxic ammonia into microbial protein, reducing water toxicity and improving fish health. Traditional pond culture relies on natural microbial activity and water exchange, often resulting in higher ammonia accumulation and increased stress on tilapia.

Zero Water Exchange Protocol

Biofloc Technology in tilapia farming minimizes water usage through a Zero Water Exchange Protocol, enhancing nutrient recycling and maintaining water quality by promoting beneficial microbial communities. Traditional pond culture relies heavily on continuous water exchange, leading to higher water consumption and potential environmental impacts due to effluent discharge.

In-situ Floc Harvesting

Biofloc technology enhances tilapia production by promoting in-situ floc harvesting, which recycles nutrients and maintains higher water quality compared to traditional pond culture. This method reduces feed costs and improves growth rates by providing a natural, protein-rich food source within the pond environment.

Microbial Protein Supplementation

Biofloc Technology enhances tilapia growth by supplementing microbial protein directly in the water, reducing feed costs and improving water quality compared to Traditional Pond Culture. This microbial protein acts as a sustainable, high-quality nutrient source that promotes fish health and increases production efficiency in aquaculture systems.

Sludge Management in Floc Systems

Biofloc technology in tilapia aquaculture significantly reduces sludge accumulation compared to traditional pond culture by promoting microbial aggregation that efficiently recycles nutrients within the system. This biofloc system enhances water quality management and minimizes solid waste buildup, resulting in improved sludge management and sustainable production practices.

Nitrogenous Waste Volatilization

Biofloc Technology significantly reduces nitrogenous waste volatilization in tilapia farming by promoting microbial assimilation of ammonia into microbial protein, thereby enhancing water quality and minimizing off-gassing of harmful nitrogen compounds. In contrast, traditional pond culture relies heavily on natural microbial activity and water exchange, leading to higher ammonia volatilization rates and increased environmental nitrogen pollution.

Biofloc Technology vs Traditional Pond Culture for tilapia Infographic

agridif.com

agridif.com