Mechanical aeration provides consistent oxygenation and efficient water circulation in prawn hatcheries, enhancing larval survival rates. Paddlewheel aeration generates strong surface agitation, promoting gas exchange and preventing sediment buildup, which is crucial for maintaining water quality. Comparing the two, paddlewheels are often favored for larger hatchery setups due to their superior mixing capabilities, while mechanical aerators are suited for smaller or more controlled environments.

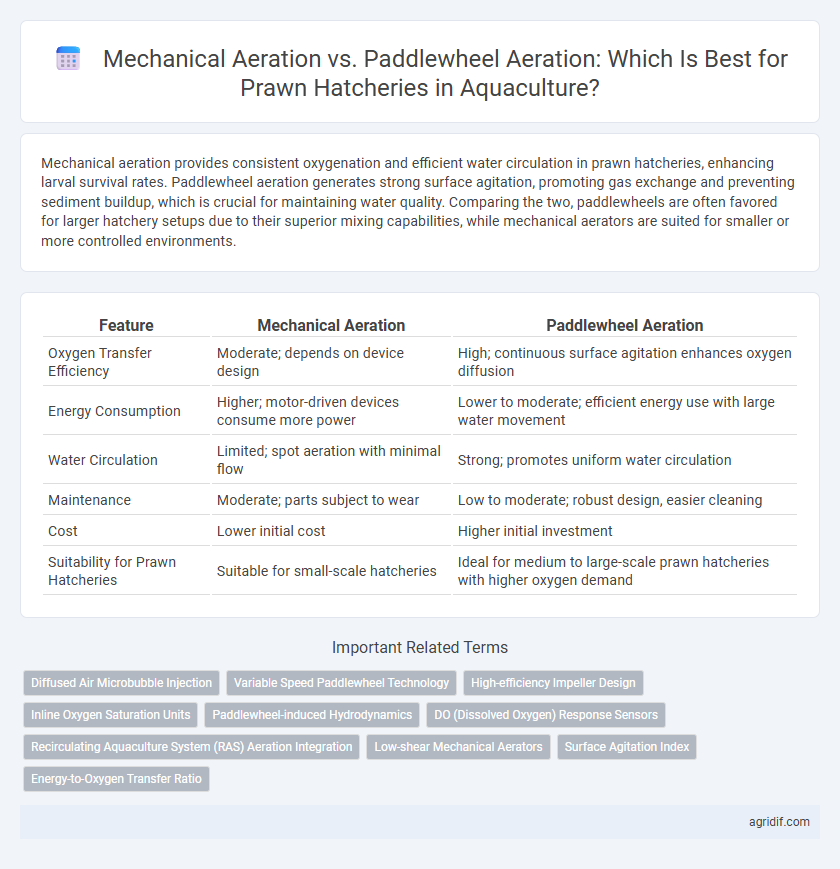

Table of Comparison

| Feature | Mechanical Aeration | Paddlewheel Aeration |

|---|---|---|

| Oxygen Transfer Efficiency | Moderate; depends on device design | High; continuous surface agitation enhances oxygen diffusion |

| Energy Consumption | Higher; motor-driven devices consume more power | Lower to moderate; efficient energy use with large water movement |

| Water Circulation | Limited; spot aeration with minimal flow | Strong; promotes uniform water circulation |

| Maintenance | Moderate; parts subject to wear | Low to moderate; robust design, easier cleaning |

| Cost | Lower initial cost | Higher initial investment |

| Suitability for Prawn Hatcheries | Suitable for small-scale hatcheries | Ideal for medium to large-scale prawn hatcheries with higher oxygen demand |

Introduction to Aeration Methods in Prawn Hatcheries

Mechanical aeration in prawn hatcheries typically involves the use of air blowers and diffusers to efficiently increase dissolved oxygen levels in rearing tanks. Paddlewheel aeration generates surface agitation and water circulation, promoting oxygen transfer and maintaining uniform water quality throughout the hatchery environment. Both methods are critical for optimizing prawn larval survival rates and supporting healthy growth in hatchery systems.

Overview of Mechanical Aeration Systems

Mechanical aeration systems in prawn hatcheries use motors to power impellers or diffusers that introduce oxygen into the water, enhancing dissolved oxygen levels essential for larval development. These systems provide consistent aeration, improving water circulation and preventing stratification, crucial for maintaining optimal growth conditions in aquaculture tanks. Mechanical aeration offers scalability and energy efficiency, making it suitable for high-density prawn hatchery operations where precise oxygen control is vital.

Understanding Paddlewheel Aeration Technology

Paddlewheel aeration technology in prawn hatcheries enhances oxygen transfer more efficiently than traditional mechanical aerators by creating a consistent water flow that increases surface agitation and aeration rates. This method promotes better gas exchange, reduces stratification, and maintains optimal dissolved oxygen levels critical for prawn larval development. Paddlewheel systems also offer energy efficiency advantages and improved scalability for large-scale hatchery operations.

Comparative Oxygen Transfer Efficiency

Mechanical aeration and paddlewheel aeration differ significantly in oxygen transfer efficiency in prawn hatcheries, with paddlewheel systems generally providing higher dissolved oxygen levels due to better surface agitation and water circulation. Mechanical aerators, such as airlifts or diffusers, often have lower oxygen transfer rates but can be more energy-efficient and suitable for smaller or less intensive setups. Optimizing oxygen transfer efficiency is crucial for prawn larval survival and growth, making paddlewheel aeration preferable for large-scale hatcheries requiring consistent and high oxygenation.

Energy Consumption and Operational Costs

Mechanical aeration in prawn hatcheries typically consumes less energy and incurs lower operational costs compared to paddlewheel aeration due to its more efficient oxygen transfer rates and targeted mixing capabilities. Paddlewheel aerators, while effective for larger culture ponds, often require higher electricity usage and frequent maintenance, increasing long-term operational expenses. Optimizing energy consumption in prawn hatcheries involves selecting aeration equipment that balances oxygenation efficiency with cost-effective power usage, where mechanical aerators generally outperform paddlewheel systems.

Impact on Water Quality Parameters

Mechanical aeration in prawn hatcheries enhances dissolved oxygen levels effectively, promoting optimal growth and survival rates by reducing ammonia and nitrite concentrations. Paddlewheel aeration, while also increasing oxygen transfer, excels in maintaining uniform water circulation, thereby preventing stratification and accumulation of harmful gases in the water column. Both methods significantly influence key water quality parameters such as pH, turbidity, and salinity, but paddlewheel aerators offer superior control over sediment resuspension, ultimately supporting healthier prawn larvae environments.

Effects on Prawn Growth and Survival Rates

Mechanical aeration in prawn hatcheries ensures consistent oxygen distribution, promoting higher growth rates and improved survival by maintaining optimal dissolved oxygen levels. Paddlewheel aeration enhances water circulation and surface agitation, which increases oxygen exchange and reduces harmful gas buildup, positively influencing prawn health and development. Studies indicate that combining both aeration methods can maximize prawn growth performance and survival rates by providing stable and well-oxygenated environments suited for intensive hatchery conditions.

Maintenance and Durability Considerations

Mechanical aeration systems in prawn hatcheries typically demand more frequent maintenance due to moving parts susceptible to wear and biofouling, requiring regular cleaning and part replacement to ensure optimal oxygenation. Paddlewheel aerators, constructed with durable materials and fewer intricate components, generally offer enhanced longevity and reduced maintenance intervals, making them cost-effective for continuous operation. Evaluating the maintenance schedules and lifespan of each aeration type is critical for sustainable hatchery management and minimizing downtime in prawn cultivation.

Suitability for Different Hatchery Scales

Mechanical aeration systems offer precise oxygen control suitable for small to medium prawn hatcheries, ensuring consistent water quality with lower energy consumption. Paddlewheel aeration, with its robust water circulation and higher oxygen transfer rates, is ideal for large-scale hatcheries requiring intensive aeration and efficient waste dispersion. Choosing between these methods depends on hatchery size, water volume, and operational costs, with mechanical aerators favored in confined settings and paddlewheels in expansive culture systems.

Choosing the Optimal Aeration System for Prawn Hatcheries

Mechanical aeration systems in prawn hatcheries provide consistent oxygen transfer rates essential for larval development, while paddlewheel aerators enhance water circulation and prevent sediment buildup. Optimal aeration balances dissolved oxygen levels and water movement to support prawn health and growth, reducing stress and mortality rates. Selecting the appropriate system depends on hatchery size, energy efficiency, and maintenance requirements, with paddlewheel aerators favored for larger, flow-through operations.

Related Important Terms

Diffused Air Microbubble Injection

Diffused air microbubble injection enhances oxygen transfer efficiency in prawn hatcheries by delivering fine bubbles directly into the water column, promoting better gas exchange and reducing energy consumption compared to paddlewheel aeration. Mechanical aeration methods like paddlewheels create surface agitation but often result in lower oxygen dissolution and increased stress on larval prawns due to turbulence.

Variable Speed Paddlewheel Technology

Variable Speed Paddlewheel Technology in prawn hatcheries enhances oxygenation efficiency by allowing precise control of aeration intensity, which optimizes water circulation and reduces energy consumption. This technology outperforms traditional mechanical aeration by minimizing stress on prawn larvae and improving overall survival rates through consistent dissolved oxygen levels.

High-efficiency Impeller Design

High-efficiency impeller designs in mechanical aeration systems deliver superior oxygen transfer rates and energy savings compared to conventional paddlewheel aeration in prawn hatcheries. Optimized impellers ensure uniform water circulation and enhanced dissolved oxygen levels, crucial for larval health and growth performance in intensive aquaculture setups.

Inline Oxygen Saturation Units

Inline oxygen saturation units integrated with mechanical aeration systems in prawn hatcheries ensure precise control of dissolved oxygen levels, enhancing larval survival rates and growth efficiency. Paddlewheel aeration, while effective for water circulation, often lacks the fine-tuned oxygen delivery capabilities offered by inline units, making mechanical aeration more suitable for optimizing hatchery oxygen management.

Paddlewheel-induced Hydrodynamics

Paddlewheel aeration in prawn hatcheries generates highly effective hydrodynamics by creating uniform water circulation that enhances oxygen distribution and waste suspension, leading to improved larval growth and survival rates. Compared to mechanical aerators, paddlewheel-induced flow patterns minimize dead zones and reduce energy consumption, optimizing tank conditions crucial for early-stage prawn development.

DO (Dissolved Oxygen) Response Sensors

Mechanical aeration in prawn hatcheries typically delivers higher dissolved oxygen (DO) levels through continuous, high-efficiency oxygen transfer supported by DO response sensors that optimize aeration cycles based on real-time oxygen demand. Paddlewheel aeration provides targeted water circulation enhancing oxygen distribution but relies on less responsive DO sensors, potentially leading to uneven oxygen saturation in critical hatchery zones.

Recirculating Aquaculture System (RAS) Aeration Integration

Mechanical aeration systems in prawn hatcheries within Recirculating Aquaculture Systems (RAS) optimize oxygen transfer efficiency and energy consumption, crucial for maintaining water quality and supporting high-density prawn larval cultures. Paddlewheel aeration offers enhanced surface agitation and improved gas exchange but may require higher maintenance and energy inputs, making integration decisions dependent on hatchery scale and specific oxygenation demands.

Low-shear Mechanical Aerators

Low-shear mechanical aerators reduce stress and physical damage to delicate prawn larvae by providing gentle oxygenation compared to high-shear paddlewheel systems, which generate turbulent water flow. Optimizing dissolved oxygen levels with low-shear aeration enhances larval survival rates and supports healthier growth in prawn hatcheries.

Surface Agitation Index

Mechanical aeration in prawn hatcheries provides consistent oxygenation by enhancing water circulation, but paddlewheel aeration achieves a higher Surface Agitation Index (SAI), crucial for maintaining uniform dissolved oxygen levels and preventing stratification. The elevated SAI associated with paddlewheel aeration improves larval survival rates and growth performance by maximizing oxygen transfer efficiency at the water's surface.

Energy-to-Oxygen Transfer Ratio

Mechanical aeration systems in prawn hatcheries offer consistent oxygen transfer but often consume more energy compared to paddlewheel aeration. Paddlewheel aerators demonstrate a higher energy-to-oxygen transfer ratio, optimizing operational costs and reducing environmental impact in intensive aquaculture setups.

Mechanical Aeration vs Paddlewheel Aeration for Prawn Hatcheries Infographic

agridif.com

agridif.com