Recirculating Aquaculture Systems (RAS) offer significant water conservation and improved biosecurity compared to traditional Flow-Through Systems by continuously filtering and reusing water within a closed loop. RAS enable precise control over water quality, temperature, and waste management, promoting healthier fish growth and reducing environmental impact. Conversely, Flow-Through Systems rely on a steady supply of fresh water that flows directly through tanks, resulting in higher water usage and potential contamination risks.

Table of Comparison

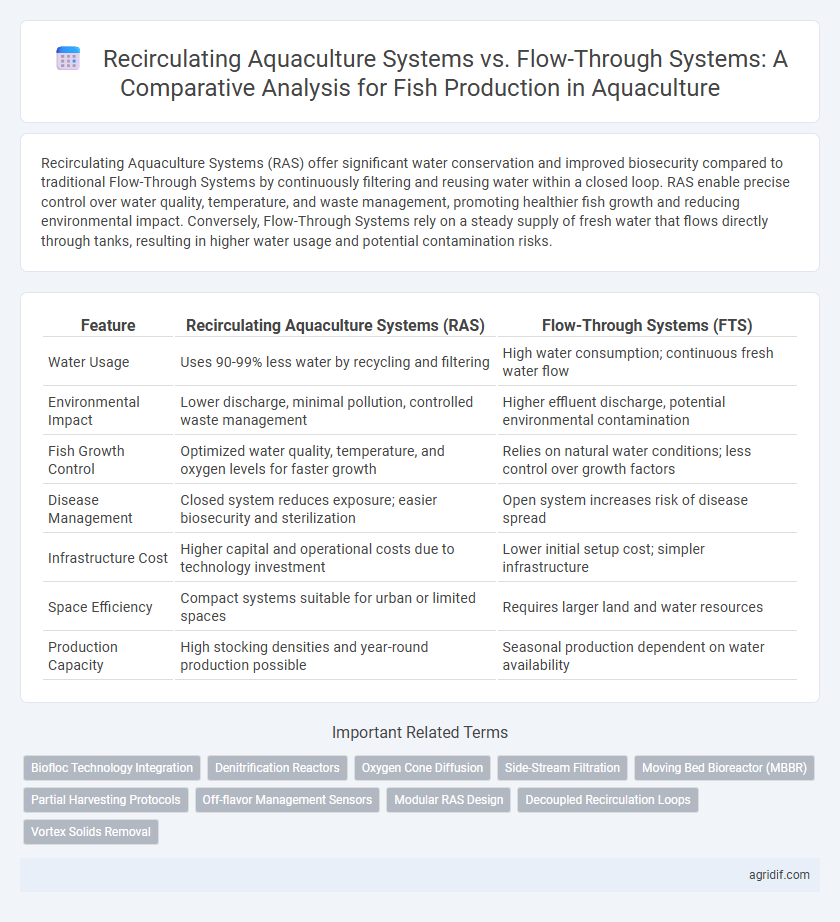

| Feature | Recirculating Aquaculture Systems (RAS) | Flow-Through Systems (FTS) |

|---|---|---|

| Water Usage | Uses 90-99% less water by recycling and filtering | High water consumption; continuous fresh water flow |

| Environmental Impact | Lower discharge, minimal pollution, controlled waste management | Higher effluent discharge, potential environmental contamination |

| Fish Growth Control | Optimized water quality, temperature, and oxygen levels for faster growth | Relies on natural water conditions; less control over growth factors |

| Disease Management | Closed system reduces exposure; easier biosecurity and sterilization | Open system increases risk of disease spread |

| Infrastructure Cost | Higher capital and operational costs due to technology investment | Lower initial setup cost; simpler infrastructure |

| Space Efficiency | Compact systems suitable for urban or limited spaces | Requires larger land and water resources |

| Production Capacity | High stocking densities and year-round production possible | Seasonal production dependent on water availability |

Introduction to Modern Fish Farming Systems

Recirculating Aquaculture Systems (RAS) offer advanced water treatment technologies that enable high-density fish production with minimal water exchange, promoting sustainability and biosecurity. Flow-Through Systems rely on continuous freshwater input, leading to higher water consumption and environmental discharge, but are simpler and often less expensive to implement initially. Modern fish farming increasingly favors RAS due to its efficiency in resource use, disease control, and adaptability to urban or land-based environments.

Overview of Recirculating Aquaculture Systems (RAS)

Recirculating Aquaculture Systems (RAS) utilize advanced water treatment technologies to continuously filter and reuse water, significantly reducing water consumption compared to Flow-Through Systems. These systems maintain optimal water quality by integrating biofiltration, mechanical filtration, aeration, and disinfection processes, enabling high-density fish production in controlled environments. RAS offer superior control over environmental parameters, disease management, and resource efficiency, making them ideal for sustainable aquaculture operations.

Understanding Flow-Through Aquaculture Systems

Flow-through aquaculture systems continuously supply fresh water to fish tanks while discharging used water, ensuring stable water quality but requiring substantial water volumes and infrastructure. These systems are highly effective for species tolerant of variable water conditions and are commonly used in regions with abundant clean water resources. Compared to recirculating aquaculture systems (RAS), flow-through systems have lower initial costs but higher long-term water and energy consumption.

Water Quality Management in RAS vs Flow-Through Systems

Recirculating Aquaculture Systems (RAS) offer advanced water quality management through continuous filtration, biofiltration, and oxygenation, significantly reducing water usage compared to Flow-Through Systems. RAS maintain optimal parameters like ammonia, nitrite, and nitrate levels, enhancing fish health and growth rates by recycling and treating water in a closed loop. In contrast, Flow-Through Systems depend on constant freshwater input, making them more susceptible to fluctuations in water quality and environmental contaminants.

Environmental Impact Comparison

Recirculating Aquaculture Systems (RAS) significantly reduce environmental impact by recycling water, minimizing effluent discharge, and lowering water usage compared to Flow-Through Systems, which continuously withdraw and discharge large volumes of water, leading to habitat disruption and pollution. RAS effectively control nutrient loads and disease spread, whereas Flow-Through Systems often contribute to eutrophication and chemical contamination of surrounding ecosystems due to untreated waste release. Energy consumption in RAS can be higher but is offset by reduced water consumption and pollution, making RAS a sustainable solution for intensive fish production with lower ecological footprint.

Cost Analysis: Initial Investment and Operational Expenses

Recirculating Aquaculture Systems (RAS) require higher initial investment costs due to complex filtration, aeration, and monitoring infrastructure compared to Flow-Through Systems, which utilize natural water flow with lower setup expenses. Operational expenses for RAS include energy-intensive water recirculation, advanced waste treatment, and labor for system maintenance, whereas Flow-Through Systems incur higher water usage fees and potential environmental compliance costs. Cost efficiency in RAS improves over time through water conservation and biosecurity benefits, while Flow-Through Systems generally have fluctuating operational costs driven by water sourcing and discharge management.

Fish Health and Disease Control Differences

Recirculating Aquaculture Systems (RAS) provide superior fish health management by maintaining controlled water quality and minimizing exposure to external pathogens, significantly reducing disease outbreaks compared to Flow-Through Systems. RAS use advanced biofiltration and continuous monitoring, which helps prevent the accumulation of harmful bacteria and parasites, while Flow-Through Systems rely on constant water replacement but are more vulnerable to environmental contaminants. Disease control in RAS is enhanced by quarantine capabilities and closed-loop water use, limiting pathogen introduction, whereas Flow-Through Systems face higher risks due to open water exchange and fluctuating conditions.

Production Efficiency and Yield Potential

Recirculating aquaculture systems (RAS) offer superior production efficiency by recycling water and maintaining optimal water quality, enabling higher stocking densities and reduced water usage compared to flow-through systems. The controlled environment in RAS minimizes disease outbreaks and enhances growth rates, resulting in increased yield potential per unit area. Flow-through systems, while simpler, often require large volumes of water and face challenges with waste management, limiting their scalability and production intensity.

Scalability and Flexibility in System Design

Recirculating Aquaculture Systems (RAS) offer superior scalability by enabling precise control over water quality, temperature, and oxygen levels, allowing for higher stocking densities and year-round production independent of external water sources. Their modular design supports flexible system expansion and customization to match production goals and available space, making them ideal for diverse species and varying production scales. In contrast, Flow-Through Systems rely on continuous water exchange, limiting scalability due to dependence on consistent water supply and environmental conditions, and offering less flexibility in adapting infrastructure to changing demands.

Future Trends in Aquaculture System Development

Recirculating Aquaculture Systems (RAS) offer enhanced water use efficiency and biosecurity compared to traditional Flow-Through Systems, driving their increasing adoption in sustainable fish production. Emerging trends emphasize integration of advanced sensor technologies, automation, and AI-driven monitoring to optimize water quality and fish health in RAS environments. Future aquaculture development prioritizes minimizing environmental footprint while maximizing production through renewable energy use and circular economy principles within recirculating setups.

Related Important Terms

Biofloc Technology Integration

Recirculating Aquaculture Systems (RAS) combined with Biofloc Technology (BFT) enhance water quality by promoting microbial communities that convert waste into usable protein, reducing water exchange and operational costs compared to Flow-Through Systems. Integrating BFT in RAS supports sustainable fish production by improving feed conversion ratios and minimizing environmental impact through nutrient recycling and disease control.

Denitrification Reactors

Denitrification reactors in recirculating aquaculture systems (RAS) efficiently remove nitrate buildup by converting it to nitrogen gas, significantly enhancing water quality and reducing environmental impact compared to flow-through systems. These reactors enable RAS to maintain optimal fish health and maximize production density by recycling water and minimizing effluent discharge, unlike conventional flow-through setups that rely on constant water exchange.

Oxygen Cone Diffusion

Recirculating Aquaculture Systems (RAS) utilize Oxygen Cone Diffusion to enhance oxygen transfer efficiency, reducing gas bubble size and increasing oxygen dissolution rates compared to Flow-Through Systems, which rely on natural aeration methods with lower oxygen transfer efficiency. The superior oxygen transfer in RAS supports higher stocking densities and improves fish growth rates while minimizing water usage and environmental discharge.

Side-Stream Filtration

Side-stream filtration in recirculating aquaculture systems (RAS) enhances water quality by continuously removing suspended solids and dissolved wastes, reducing the need for frequent water exchange typical in flow-through systems. This targeted filtration method improves fish health and growth rates by maintaining optimal environmental conditions and minimizing waste discharge into surrounding ecosystems.

Moving Bed Bioreactor (MBBR)

Recirculating Aquaculture Systems (RAS) utilizing Moving Bed Bioreactor (MBBR) technology offer superior water quality management and reduced environmental impact compared to traditional Flow-Through Systems, enabling higher fish density and improved biofiltration efficiency. The MBBR enhances nitrogen removal by providing a large surface area for microbial growth, optimizing ammonia oxidation while minimizing water exchange, which is critical for sustainable fish production.

Partial Harvesting Protocols

Partial harvesting protocols in Recirculating Aquaculture Systems (RAS) enable precise control over fish biomass removal, improving water quality management and minimizing stress on remaining stock compared to Flow-Through Systems, where continuous water exchange limits harvesting flexibility. Implementing staged partial harvests in RAS enhances production efficiency and disease control by maintaining optimal environmental parameters during successive harvest cycles.

Off-flavor Management Sensors

Recirculating Aquaculture Systems (RAS) employ advanced off-flavor management sensors to continuously monitor and detect geosmin and MIB compounds, enabling precise water quality control and reducing fish off-flavors more effectively than Flow-Through Systems. These sensors integrate with automated filtration units in RAS, optimizing water recirculation and minimizing off-flavor accumulation, resulting in higher-quality fish production and improved marketability.

Modular RAS Design

Modular Recirculating Aquaculture Systems (RAS) offer enhanced water efficiency and waste management compared to traditional flow-through systems by recycling and filtering water within contained units. This modular approach allows scalable fish production with precise environmental control, reducing operational costs and environmental impact while improving fish health and growth rates.

Decoupled Recirculation Loops

Decoupled Recirculation Loops in Recirculating Aquaculture Systems (RAS) enhance water quality control by isolating biofiltration from fish tanks, reducing stress and disease risk compared to traditional Flow-Through Systems. This configuration optimizes oxygen levels and waste removal efficiency, enabling sustainable fish production with lower water consumption and improved growth rates.

Vortex Solids Removal

Recirculating Aquaculture Systems (RAS) utilize vortex solids removal to efficiently separate and remove suspended solids from water, enhancing water quality and reducing waste accumulation compared to Flow-Through Systems. This technology enables higher stocking densities and improved environmental control, promoting sustainable fish production with minimized water usage and effluent discharge.

Recirculating Aquaculture Systems vs Flow-Through Systems for fish production Infographic

agridif.com

agridif.com