Open pond systems for shrimp production offer natural environmental conditions and lower initial costs but face challenges such as disease outbreaks and water quality fluctuations. Closed tank systems provide controlled environments that enhance biosecurity, optimize growth rates, and reduce pollution risks, though they require higher capital investment and operational expertise. Selecting between open ponds and closed tanks depends on specific farm objectives, budget constraints, and environmental considerations.

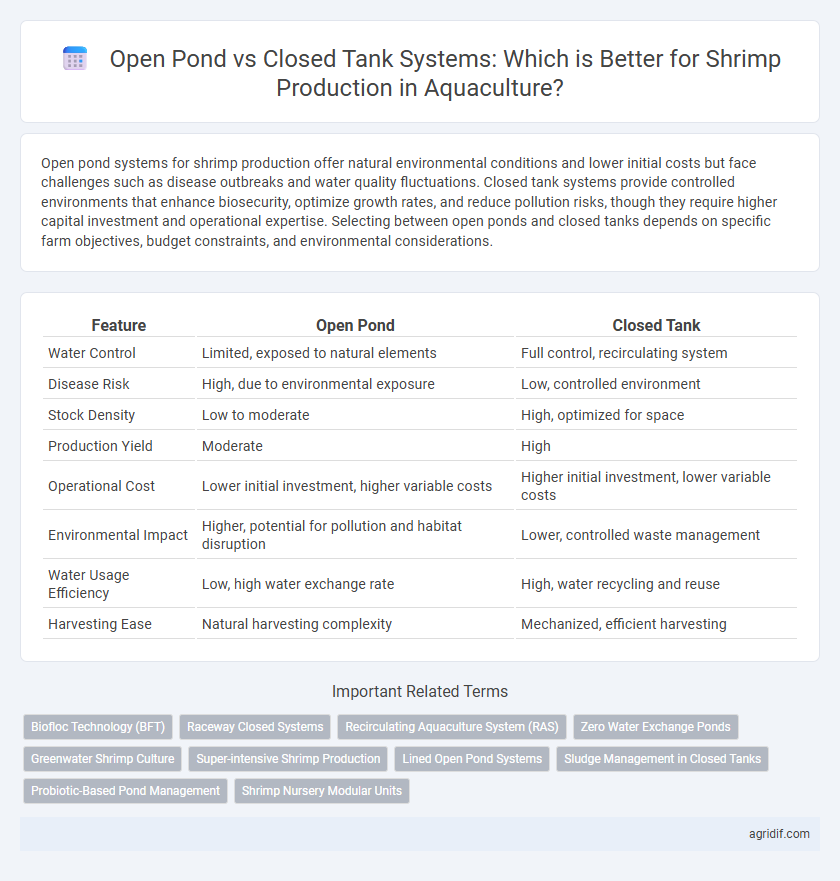

Table of Comparison

| Feature | Open Pond | Closed Tank |

|---|---|---|

| Water Control | Limited, exposed to natural elements | Full control, recirculating system |

| Disease Risk | High, due to environmental exposure | Low, controlled environment |

| Stock Density | Low to moderate | High, optimized for space |

| Production Yield | Moderate | High |

| Operational Cost | Lower initial investment, higher variable costs | Higher initial investment, lower variable costs |

| Environmental Impact | Higher, potential for pollution and habitat disruption | Lower, controlled waste management |

| Water Usage Efficiency | Low, high water exchange rate | High, water recycling and reuse |

| Harvesting Ease | Natural harvesting complexity | Mechanized, efficient harvesting |

Overview of Open Pond and Closed Tank Shrimp Farming

Open pond shrimp farming involves cultivating shrimp in natural or artificial ponds, leveraging sunlight and natural water exchange to promote growth, often resulting in lower initial costs but higher risks of contamination and water quality fluctuations. Closed tank shrimp farming employs controlled recirculating aquaculture systems (RAS), enabling precise regulation of environmental parameters such as temperature, oxygen levels, and waste removal, which enhances biosecurity and production efficiency. These contrasting methods impact factors like disease management, water usage, and shrimp yield, influencing the sustainability and scalability of shrimp production operations.

Key Differences Between Open Pond and Closed Tank Systems

Open pond systems for shrimp production utilize natural water bodies or earthen ponds, offering lower initial costs but higher vulnerability to environmental fluctuations and disease outbreaks. Closed tank systems feature controlled environments with advanced filtration and monitoring technologies, enabling optimized water quality and biosecurity at a higher operational expense. The key differences lie in water management precision, disease control capabilities, and scalability potential for sustainable shrimp aquaculture.

Environmental Impact: Pond vs. Tank in Shrimp Aquaculture

Open ponds in shrimp aquaculture often lead to water pollution and habitat disruption due to nutrient runoff and waste discharge into surrounding ecosystems. Closed tanks provide a controlled environment that minimizes effluent release, reducing the risk of contaminating natural water bodies and improving biosecurity against disease outbreaks. The use of closed systems supports sustainable shrimp production by enabling better waste management and lowering the environmental footprint compared to traditional open pond methods.

Water Quality Management in Open Ponds vs Closed Tanks

Open ponds in shrimp aquaculture rely on natural water exchange and biological filtration, which can result in fluctuating water quality parameters such as dissolved oxygen, pH, and ammonia levels. Closed tanks offer precise control over water quality through mechanical filtration, aeration systems, and biofilters, enabling stable conditions that reduce disease risk and improve shrimp growth rates. Effective water quality management in closed tanks minimizes environmental impact and allows for higher stocking densities compared to the variable conditions in open pond systems.

Disease Control and Biosecurity Considerations

Closed tank systems offer superior disease control and biosecurity compared to open ponds by minimizing pathogen exposure and allowing for better water quality management. These systems enable more effective isolation of shrimp populations, reducing the risk of disease outbreaks and facilitating targeted treatment protocols. In contrast, open ponds are more vulnerable to contamination from environmental sources, increasing the likelihood of disease transmission and complicating biosecurity measures.

Shrimp Growth Rates and Yield Comparisons

Closed tank systems for shrimp production often deliver higher growth rates and yield due to better control over water quality, temperature, and disease management compared to open ponds. Shrimp in closed tanks can achieve up to 20-30% faster growth rates, with yields reaching 15-20 tons per hectare annually, while open ponds typically yield 5-10 tons per hectare with slower growth. Enhanced biosecurity and optimized feeding in closed tanks reduce mortality and improve feed conversion ratios, resulting in more efficient shrimp production.

Operational Costs: Open Pond vs Closed Tank Production

Operational costs in open pond shrimp production are generally lower due to less infrastructure investment and reliance on natural water exchange, whereas closed tank systems require higher initial capital and continuous energy inputs for water circulation and aeration. Closed tanks offer better control over environmental parameters, reducing disease risk and potentially lowering costs related to stock loss and treatments, but these savings may be offset by increased energy and maintenance expenses. Efficient management of feed and water quality in both systems directly influences production costs and overall economic viability.

Resource Utilization and Sustainability Factors

Open ponds for shrimp production leverage natural sunlight and ecosystem services, reducing energy consumption and operational costs, while promoting biodiversity through habitat complexity. Closed tanks enable precise control over water quality and waste management, minimizing pathogen risks and enabling water recirculation systems that enhance resource efficiency and sustainability. Balancing open pond expanses with intensive closed system technology optimizes water use, feed conversion ratios, and environmental footprint in aquaculture operations.

Technological Advancements in Shrimp Farming Systems

Technological advancements in shrimp farming have significantly improved both open pond and closed tank systems, enhancing production efficiency and sustainability. Recirculating aquaculture systems (RAS) in closed tanks provide superior water quality control, disease management, and biosecurity, leading to higher shrimp survival rates and faster growth. Conversely, innovations in open pond aeration, automated feeding, and water monitoring have optimized environmental conditions, reducing operational costs and environmental impact while maintaining high yield.

Choosing the Right System: Recommendations for Shrimp Farmers

Open pond systems provide natural modeling of shrimp growth through exposure to the environment, offering cost-effective solutions with higher yields but elevated risks of disease and water quality fluctuation. Closed tank systems ensure controlled water conditions, reduced pathogen exposure, and enhanced biosecurity, allowing for precise management of shrimp nutrition and growth rates, though with higher operational costs and energy input. Shrimp farmers should evaluate factors such as local climate, budget constraints, desired production scale, and risk tolerance to select the optimal system for sustainable and profitable shrimp farming.

Related Important Terms

Biofloc Technology (BFT)

Biofloc Technology (BFT) enhances shrimp production by promoting beneficial microbial communities that improve water quality and nutrient recycling in both open pond and closed tank systems; closed tanks offer more control over environmental parameters and biofloc composition, leading to higher shrimp densities and reduced disease risks. Open ponds benefit from natural sunlight and lower operational costs, but face challenges in maintaining optimal biofloc balance and water quality stability compared to the more intensively managed closed tank systems.

Raceway Closed Systems

Raceway closed systems in shrimp production optimize water quality and disease management by controlling environmental parameters more effectively than open ponds, resulting in higher shrimp density and improved growth rates. These systems utilize continuous water circulation and filtration, reducing waste accumulation and enhancing biosecurity for sustainable aquaculture operations.

Recirculating Aquaculture System (RAS)

Recirculating Aquaculture Systems (RAS) offer superior water quality control and biosecurity compared to open ponds in shrimp production, reducing disease outbreaks and environmental impact. Closed tanks in RAS enable efficient waste management and oxygen regulation, resulting in higher shrimp growth rates and consistent production cycles.

Zero Water Exchange Ponds

Zero water exchange ponds in shrimp production offer significant biosecurity advantages by minimizing waterborne pathogen entry compared to open ponds, which rely heavily on natural water sources and continuous exchange. Closed tank systems provide tighter environmental control but involve higher capital costs, whereas zero water exchange ponds strike a balance with lower operational expenses and reduced ecological impact.

Greenwater Shrimp Culture

Open ponds for greenwater shrimp culture provide natural sunlight and biofloc formation, enhancing algal growth and nutrient cycling which support shrimp health and growth. Closed tanks offer better control over water quality and biosecurity, reducing disease risks but require advanced filtration and aeration systems to maintain optimal greenwater conditions.

Super-intensive Shrimp Production

Super-intensive shrimp production favors closed tank systems over open ponds due to enhanced biosecurity, precise water quality control, and increased stocking densities reaching up to 500 shrimp/m2. Closed tanks minimize disease outbreaks and environmental impact while enabling optimized feed conversion ratios and faster growth cycles in shrimp aquaculture.

Lined Open Pond Systems

Lined open pond systems for shrimp production offer enhanced water retention and reduced seepage compared to traditional earthen ponds, improving biosecurity and water quality management. These systems facilitate cost-effective large-scale shrimp farming by minimizing environmental impact and optimizing feed conversion ratios.

Sludge Management in Closed Tanks

Closed tank shrimp production systems enhance sludge management by enabling precise control over waste accumulation and facilitating regular sludge removal through mechanical or hydraulic means. This containment minimizes environmental impact and promotes water quality stability, leading to improved shrimp health and higher production efficiency compared to open pond systems.

Probiotic-Based Pond Management

Probiotic-based pond management in open pond systems enhances water quality by promoting beneficial microbial communities that suppress pathogens and reduce harmful nutrient buildup, improving shrimp health and yield. In closed tank systems, probiotics facilitate controlled microbial balance and optimize biofilter efficiency, enabling consistent water quality and higher shrimp density with minimized disease outbreaks.

Shrimp Nursery Modular Units

Shrimp nursery modular units in closed tank systems offer controlled water quality, reducing disease risk and improving early-stage shrimp survival rates compared to open pond systems. These modular units enable precise management of temperature, salinity, and feeding, optimizing growth performance and yield efficiency in hatchery and nursery phases.

Open Pond vs Closed Tank for Shrimp Production Infographic

agridif.com

agridif.com