Manual harvesting offers precision and selectivity, allowing workers to carefully pick crops without damaging plants, which is ideal for delicate produce but requires significant labor and time. Mechanical harvesting significantly increases labor efficiency by rapidly collecting large quantities of crops, reducing the need for extensive manual labor while potentially causing more crop damage and higher initial equipment costs. Balancing these methods depends on crop type, labor availability, and cost-effectiveness to optimize overall productivity.

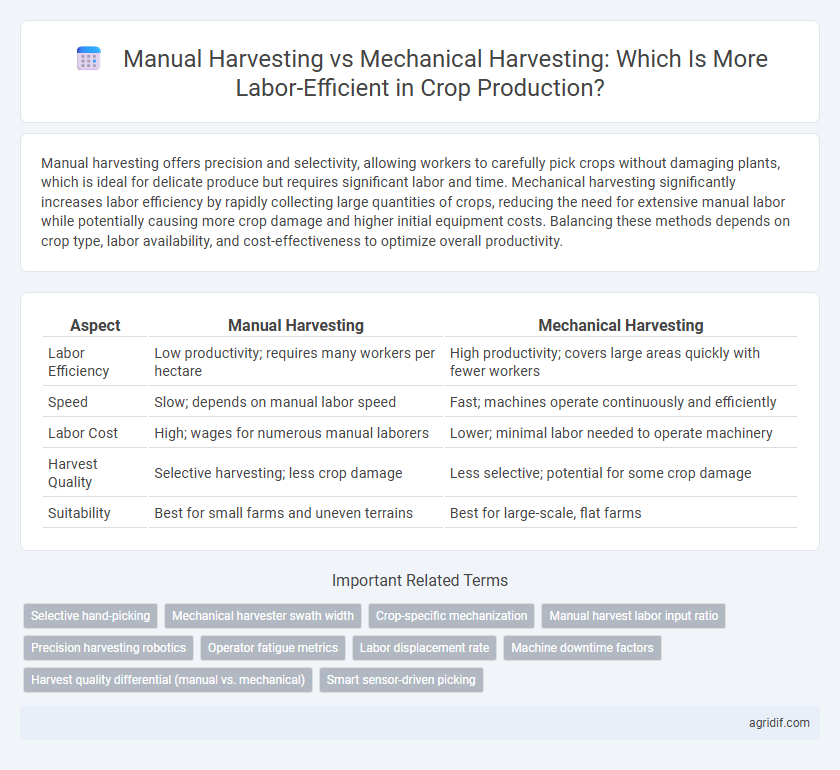

Table of Comparison

| Aspect | Manual Harvesting | Mechanical Harvesting |

|---|---|---|

| Labor Efficiency | Low productivity; requires many workers per hectare | High productivity; covers large areas quickly with fewer workers |

| Speed | Slow; depends on manual labor speed | Fast; machines operate continuously and efficiently |

| Labor Cost | High; wages for numerous manual laborers | Lower; minimal labor needed to operate machinery |

| Harvest Quality | Selective harvesting; less crop damage | Less selective; potential for some crop damage |

| Suitability | Best for small farms and uneven terrains | Best for large-scale, flat farms |

Introduction to Harvesting Methods in Agriculture

Manual harvesting in agriculture remains essential for delicate crops requiring precision and minimal damage, while mechanical harvesting significantly increases labor efficiency by rapidly processing large fields with fewer workers. Mechanical harvesters reduce labor costs and time, enabling farmers to manage larger acreages, but they may not be suitable for all crop types due to potential quality issues. Selecting the appropriate harvesting method depends on crop characteristics, labor availability, and economic considerations to optimize productivity.

Manual Harvesting: Techniques and Tools

Manual harvesting employs precise techniques such as handpicking, sickle cutting, and selective picking, which optimize crop quality and minimize damage. Tools like handheld knives, shears, and traditional sickles enhance labor efficiency by enabling workers to target ripe produce accurately while preserving plant health. This method supports sustainable practices and is vital in terrains unsuitable for machinery or for crops requiring delicate handling.

Mechanical Harvesting: Technologies and Innovations

Mechanical harvesting technologies have significantly enhanced labor efficiency in crop production by reducing the need for manual labor and speeding up the harvesting process. Innovations such as GPS-guided combine harvesters, automated fruit-picking robots, and sensor-based yield monitors increase precision and reduce crop loss. These advancements enable farmers to cover larger areas quickly, optimize resource use, and improve overall productivity in the agricultural sector.

Labor Efficiency in Manual vs Mechanical Harvesting

Mechanical harvesting significantly enhances labor efficiency by reducing the time and workforce required to gather crops compared to manual harvesting. While manual harvesting depends heavily on skilled labor and is labor-intensive, mechanical methods can process larger fields rapidly, lowering labor costs and increasing output. Advances in harvesting machinery have further optimized the speed and precision of crop collection, making mechanical harvesting the preferred choice for large-scale agricultural operations.

Cost Implications of Different Harvesting Methods

Manual harvesting typically involves higher labor costs due to intensive human effort and longer time requirements per acre, increasing overall operational expenses. Mechanical harvesting reduces labor costs significantly by enabling faster crop collection and scalability but entails substantial initial investment and ongoing maintenance costs. Analyzing cost implications requires balancing labor savings against equipment depreciation and fuel expenses to determine the most economically viable harvesting method.

Impact on Crop Quality and Yield

Manual harvesting allows selective picking, preserving crop quality by reducing damage and minimizing bruising, which is crucial for delicate fruits and vegetables. Mechanical harvesting increases labor efficiency by rapidly covering large areas but may cause higher crop damage and loss, potentially reducing overall yield quality. Studies indicate that integrating mechanical harvesting with precision technology can optimize yield while maintaining acceptable crop quality standards.

Training and Skill Requirements for Harvesting

Manual harvesting demands extensive training and specialized skills to efficiently identify and pick crops without damage, impacting labor productivity. Mechanical harvesting reduces the need for skilled labor by relying on machines, but operators still require technical training to manage and maintain equipment effectively. Investment in operator training enhances machine efficiency and reduces downtime, making it critical for maximizing overall harvesting productivity.

Environmental Considerations of Harvesting Practices

Manual harvesting minimizes soil compaction and reduces fuel consumption compared to mechanical methods, leading to lower greenhouse gas emissions and less environmental degradation. While mechanical harvesting boosts labor efficiency and speed, it often results in increased energy use, higher carbon footprints, and potential harm to soil structure and biodiversity. Sustainable crop production requires balancing these environmental considerations to optimize labor efficiency and minimize ecological impact.

Case Studies: Comparing Labor Efficiency in Field Trials

Field trials comparing manual and mechanical harvesting reveal significant differences in labor efficiency, with mechanical methods increasing throughput by 40-60% per hour in crops like wheat and corn. Case studies from farms in the Midwest United States show that mechanical harvesters reduce labor costs by up to 30% while maintaining grain quality. These trials emphasize the importance of machine calibration and operator skill to maximize efficiency in large-scale crop production.

Future Trends in Harvesting for Enhanced Labor Productivity

Mechanical harvesting technology is rapidly advancing with the integration of artificial intelligence and robotics, significantly improving labor productivity by reducing reliance on manual labor. Precision agriculture tools enable machines to adapt to various crop types and field conditions, optimizing the harvesting process and minimizing labor costs. Future trends focus on autonomous harvesters equipped with sensors and machine learning algorithms to enhance efficiency and sustainability in crop production.

Related Important Terms

Selective hand-picking

Selective hand-picking in manual harvesting offers superior labor efficiency for crops requiring precision, minimizing damage and ensuring quality by targeting only ripe produce. Mechanical harvesting, while faster, often lacks this selectivity, leading to increased waste and potential crop loss in delicate varieties.

Mechanical harvester swath width

Mechanical harvesters with wider swath widths significantly enhance labor efficiency by covering more ground per pass, reducing the number of operational cycles needed compared to manual harvesting. High-capacity machines with swath widths ranging from 4 to 12 meters enable faster crop collection, lower labor costs, and improved productivity in large-scale agricultural operations.

Crop-specific mechanization

Mechanical harvesting enhances labor efficiency significantly for large-scale crops like wheat and corn by reducing time and physical effort compared to manual methods. Crop-specific mechanization, such as combine harvesters for grains and specialized fruit pickers for orchards, optimizes productivity by tailoring equipment to the unique characteristics of each crop.

Manual harvest labor input ratio

Manual harvesting in crop production typically requires a labor input ratio significantly higher than mechanical harvesting, with manual methods often consuming up to 60-70% more human labor hours per hectare. This increased labor intensity impacts overall efficiency and cost, especially in regions with limited access to advanced harvesting machinery.

Precision harvesting robotics

Precision harvesting robotics significantly enhance labor efficiency by automating crop selection and minimizing waste, outperforming manual harvesting methods that rely heavily on human labor and are prone to errors. These advanced systems utilize AI-driven sensors and machine learning algorithms to identify optimal harvesting times and accurately pick crops, reducing labor costs and improving yield quality in modern agriculture.

Operator fatigue metrics

Manual harvesting typically results in higher operator fatigue due to repetitive physical labor and longer working hours, reducing overall labor efficiency. Mechanical harvesting significantly lowers operator fatigue by automating intensive tasks, enabling faster work rates and increased crop production per labor hour.

Labor displacement rate

Manual harvesting requires intensive human labor, resulting in a low labor displacement rate, whereas mechanical harvesting significantly increases labor efficiency by reducing the need for manual workers, leading to higher labor displacement rates in crop production. The adoption of mechanized harvesters can displace up to 70-90% of labor traditionally employed in manual harvesting, optimizing overall productivity and reducing operational costs.

Machine downtime factors

Mechanical harvesting significantly improves labor efficiency compared to manual methods by accelerating crop collection and reducing labor hours per hectare. However, machine downtime caused by maintenance needs, operator skill levels, and equipment breakdowns can diminish overall productivity and increase operational costs.

Harvest quality differential (manual vs. mechanical)

Manual harvesting ensures superior harvest quality by minimizing crop damage and allowing selective picking, which preserves the integrity and freshness of produce. Mechanical harvesting increases labor efficiency but often results in higher rates of crop bruising, contamination, and uniformity loss due to less precise handling.

Smart sensor-driven picking

Smart sensor-driven picking in mechanical harvesting significantly boosts labor efficiency by automating crop identification and selective harvesting, reducing reliance on manual labor. Manual harvesting remains labor-intensive and slower, whereas sensor integration enhances precision, increases throughput, and lowers overall labor costs in crop production.

Manual harvesting vs Mechanical harvesting for labor efficiency Infographic

agridif.com

agridif.com