Parlor milking requires manual labor to operate milking machines, offering greater control and routine but demanding more time and physical effort. Robotic milking automates the process, allowing cows to be milked on their own schedule, enhancing efficiency and reducing labor costs. Both methods impact milk quality and animal welfare differently, with robotics promoting consistent milking and potential stress reduction.

Table of Comparison

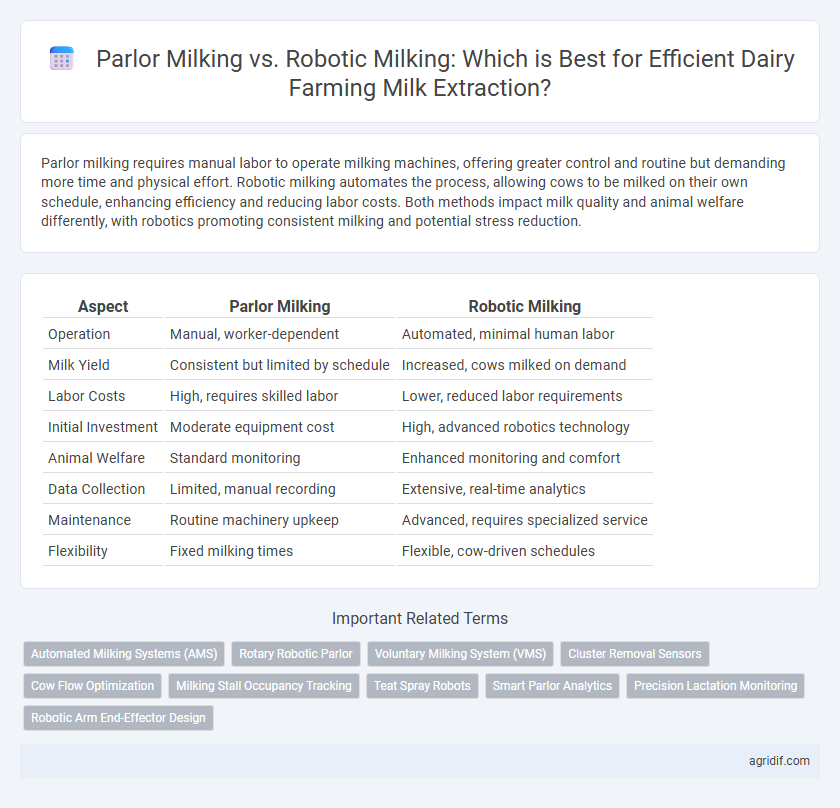

| Aspect | Parlor Milking | Robotic Milking |

|---|---|---|

| Operation | Manual, worker-dependent | Automated, minimal human labor |

| Milk Yield | Consistent but limited by schedule | Increased, cows milked on demand |

| Labor Costs | High, requires skilled labor | Lower, reduced labor requirements |

| Initial Investment | Moderate equipment cost | High, advanced robotics technology |

| Animal Welfare | Standard monitoring | Enhanced monitoring and comfort |

| Data Collection | Limited, manual recording | Extensive, real-time analytics |

| Maintenance | Routine machinery upkeep | Advanced, requires specialized service |

| Flexibility | Fixed milking times | Flexible, cow-driven schedules |

Introduction to Milking Systems in Dairy Farming

Parlor milking systems involve manual or semi-automated setups where cows enter a designated area for milk extraction by milkers, ensuring controlled herd management but requiring significant labor. Robotic milking utilizes automated machines that allow cows to self-milk at their own pace, increasing efficiency, reducing labor costs, and improving animal welfare through consistent milking schedules. Both systems impact milk yield, animal health monitoring, and overall farm productivity, with robotic milking gaining popularity for precision dairy farming.

Overview of Parlor Milking Technology

Parlor milking technology involves the use of specialized milking stalls where cows are guided into a milking area for manual or semi-automated extraction of milk. This system relies on operators to attach milking units to the udders, with machines controlling vacuum and pulsation to ensure efficient milk flow. Parlor milking is often preferred for its ability to handle large herds systematically while maintaining milking hygiene and consistency.

Understanding Robotic Milking Systems

Robotic milking systems use automated technology to extract milk, improving efficiency by operating independently without human intervention. These systems incorporate sensors and software to monitor cow health and optimize milking frequency, enhancing animal welfare and milk quality. Compared to traditional parlor milking, robotic systems reduce labor costs and provide precise data for herd management, transforming modern dairy farming.

Efficiency Comparison: Parlor vs Robotic Milking

Robotic milking systems offer higher efficiency by enabling cows to be milked multiple times daily with minimal labor, increasing milk yield and improving herd health monitoring through automated data collection. Parlor milking requires scheduled milking sessions and more labor, limiting frequency and potentially causing stress to cows, which can reduce milk production. Overall, robotic milking optimizes time management and resource use, enhancing productivity compared to traditional parlor setups.

Labor Requirements for Parlor and Robotic Milking

Parlor milking systems demand substantial labor input, requiring multiple skilled workers to handle cow preparation, milking, and post-milking tasks efficiently. Robotic milking systems significantly reduce human labor needs by automating cow identification, udder cleaning, and milk extraction, allowing one operator to manage a larger herd with minimal manual intervention. Labor cost savings and increased flexibility are key advantages of robotic milking in modern dairy farming operations.

Animal Welfare and Cow Comfort Considerations

Parlor milking systems require cows to be herded and restrained for milking, which can increase stress and reduce overall comfort compared to robotic milking systems that allow cows to choose when to be milked, promoting natural behavior and reducing stress. Robotic milking integrates sensors that monitor cow health and udder condition, enabling early detection of issues and improving animal welfare through individualized care. Enhanced cow comfort in robotic milking systems leads to higher milk yield and better reproductive performance, reflecting improved overall welfare.

Milk Quality and Hygiene: Parlor vs Robotic Approaches

Robotic milking systems enhance milk quality by enabling frequent, stress-free milking, reducing bacterial contamination through automated cleaning and consistent teat sanitation. Parlor milking relies heavily on operator skill for hygiene maintenance, with variable cleaning protocols that can impact somatic cell counts and overall milk safety. Studies show robotic systems maintain lower somatic cell counts and improved milk hygiene metrics compared to traditional parlor methods, optimizing dairy product quality.

Installation and Maintenance Costs Analysis

Parlor milking systems typically require lower initial installation costs but incur higher labor expenses over time, while robotic milking systems involve significant upfront investment due to advanced technology and automation. Maintenance costs for robotic systems are generally higher and require specialized technical support to ensure optimal performance, whereas parlor milking equipment maintenance is often simpler and less expensive. Evaluating long-term cost efficiency depends on herd size, labor availability, and farm management priorities, with robotic milking favored for high automation benefits despite increased installation and maintenance expenses.

Data Management and Precision Farming Integration

Parlor milking systems rely on manual data entry and periodic monitoring, limiting real-time insights into cow health and milk yield variations, whereas robotic milking integrates advanced sensors and automated data collection for continuous monitoring. Precision farming integration in robotic milking enables individualized cow treatment through AI-driven analytics, enhancing milk quality and herd management efficiency. Data management platforms connected to robotic systems offer seamless synchronization with farm management software, facilitating predictive maintenance and optimized resource allocation.

Future Trends in Dairy Milking Technologies

Robotic milking systems are increasingly adopted in dairy farming due to their ability to improve milking efficiency, enhance cow comfort, and provide real-time health monitoring data. Future trends indicate integration of AI and IoT technologies to optimize milk yield, reduce labor costs, and enable precision dairy management. Parlor milking remains relevant in large-scale operations but is gradually complemented or replaced by automated milking systems for sustainable production increases.

Related Important Terms

Automated Milking Systems (AMS)

Automated Milking Systems (AMS) in dairy farming enhance efficiency by allowing cows to be milked without human intervention, improving milking frequency and animal welfare compared to traditional parlor milking. AMS utilizes advanced robotics, sensors, and data analytics to monitor milk yield, quality, and cow health in real time, optimizing overall farm productivity.

Rotary Robotic Parlor

Rotary robotic parlors combine automated milking technology with high-efficiency rotary systems, enhancing milk extraction speed while reducing labor costs and improving animal welfare through consistent milking routines. These systems optimize herd management by integrating real-time data on milk yield, cow health, and milking frequency, ensuring precision and productivity in modern dairy farming operations.

Voluntary Milking System (VMS)

Voluntary Milking Systems (VMS) utilize robotic milking technology that allows cows to be milked on their own schedule, increasing milking frequency and improving animal welfare compared to traditional parlor milking. VMS enhances milk yield and quality by reducing cow stress and enabling precise data collection for individualized herd management in dairy farming operations.

Cluster Removal Sensors

Cluster removal sensors in robotic milking systems enhance dairy farm efficiency by automatically detecting milk flow cessation and detaching milking clusters without human intervention, reducing labor costs and minimizing udder stress. In contrast, traditional parlor milking relies on manual cluster removal, which can lead to inconsistent teat health management and increased risk of over-milking or under-milking.

Cow Flow Optimization

Robotic milking systems enhance cow flow optimization by allowing cows to be milked individually on their own schedule, reducing stress and improving udder health compared to traditional parlor milking, which relies on scheduled group sessions that can create bottlenecks and delays. Advanced sensors and data analytics in robotic systems streamline movement patterns and monitor cow readiness, maximizing throughput and milk yield efficiency on large-scale dairy farms.

Milking Stall Occupancy Tracking

Robotic milking systems leverage advanced sensors and real-time data analytics for precise milking stall occupancy tracking, optimizing cow flow and reducing waiting times. In contrast, parlor milking relies on manual monitoring and scheduling, which can lead to less efficient stall utilization and increased labor costs.

Teat Spray Robots

Teat spray robots in robotic milking systems ensure precise and consistent application of disinfectants, reducing mastitis risk and improving udder health compared to manual parlor milking methods. These automated teat spray technologies enhance hygiene standards and operational efficiency, leading to higher milk quality and increased herd productivity.

Smart Parlor Analytics

Smart Parlor Analytics enhances parlor milking by providing real-time data on cow health, milk yield, and milking speed, enabling optimized herd management and increased efficiency. Compared to robotic milking, these analytics offer precise control over high-volume operations while integrating seamlessly with existing dairy infrastructure for improved productivity.

Precision Lactation Monitoring

Parlor milking systems provide efficient batch processing of dairy cows, but robotic milking offers advanced precision lactation monitoring through automated sensors that track individual cow health, milk yield, and quality in real time. This data-driven approach enables timely intervention for mastitis, optimized milking schedules, and improved overall herd management, enhancing milk production efficiency and animal welfare.

Robotic Arm End-Effector Design

Robotic arm end-effector design in dairy farming enhances milking efficiency by precisely mimicking manual milking motions, reducing animal stress and improving teat health. Advanced sensor integration and adaptive gripping mechanisms ensure optimal teat attachment and cleaning, leading to higher milk yield and consistent udder hygiene.

Parlor milking vs Robotic milking for milk extraction Infographic

agridif.com

agridif.com