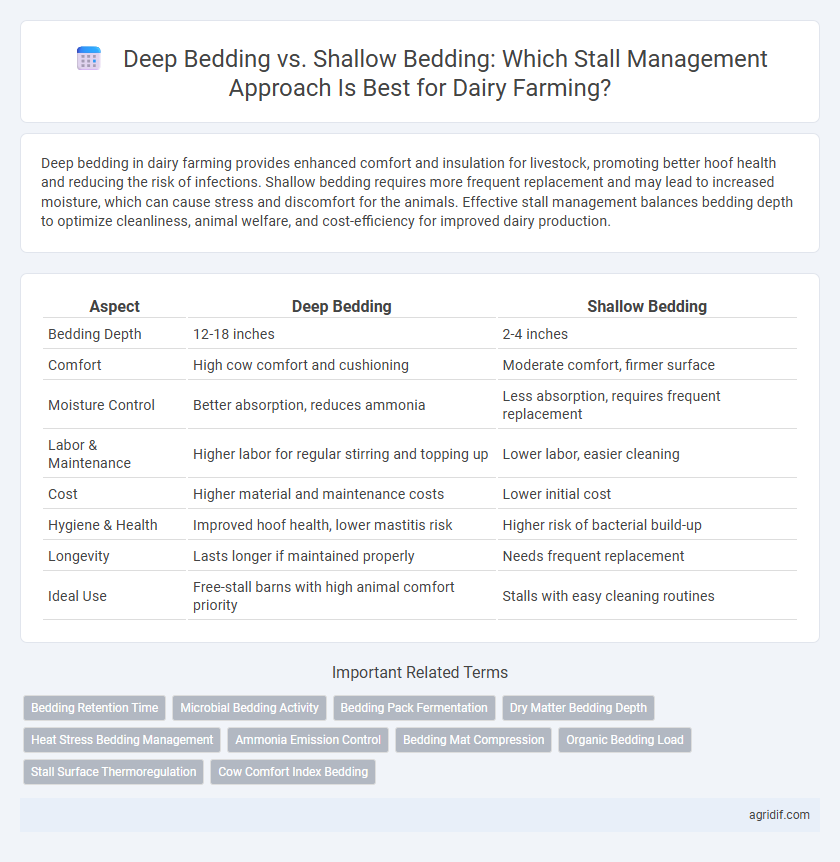

Deep bedding in dairy farming provides enhanced comfort and insulation for livestock, promoting better hoof health and reducing the risk of infections. Shallow bedding requires more frequent replacement and may lead to increased moisture, which can cause stress and discomfort for the animals. Effective stall management balances bedding depth to optimize cleanliness, animal welfare, and cost-efficiency for improved dairy production.

Table of Comparison

| Aspect | Deep Bedding | Shallow Bedding |

|---|---|---|

| Bedding Depth | 12-18 inches | 2-4 inches |

| Comfort | High cow comfort and cushioning | Moderate comfort, firmer surface |

| Moisture Control | Better absorption, reduces ammonia | Less absorption, requires frequent replacement |

| Labor & Maintenance | Higher labor for regular stirring and topping up | Lower labor, easier cleaning |

| Cost | Higher material and maintenance costs | Lower initial cost |

| Hygiene & Health | Improved hoof health, lower mastitis risk | Higher risk of bacterial build-up |

| Longevity | Lasts longer if maintained properly | Needs frequent replacement |

| Ideal Use | Free-stall barns with high animal comfort priority | Stalls with easy cleaning routines |

Introduction to Stall Bedding in Dairy Farming

Effective stall bedding in dairy farming significantly impacts cow comfort, hygiene, and overall productivity. Deep bedding systems, often utilizing materials like sand or straw, provide enhanced cushioning and moisture absorption, reducing the risk of lameness and mastitis. Shallow bedding requires more frequent replenishment but uses less material, emphasizing management practices to maintain cleanliness and cow health.

Defining Deep Bedding and Shallow Bedding

Deep bedding in dairy farming involves using thick layers of organic material such as straw, sand, or sawdust to provide cows with a soft, absorbent resting surface that promotes comfort and reduces the risk of lameness. Shallow bedding consists of thinner, less absorbent layers that may require more frequent replacement to maintain cleanliness and cow health. Optimal stall management depends on selecting the appropriate bedding depth to balance cow comfort, hygiene, and labor efficiency.

Materials Commonly Used for Bedding

Deep bedding commonly uses materials such as sawdust, chopped straw, and sand, which provide cushioning and absorb moisture effectively. Shallow bedding typically involves thinner layers of materials like wood shavings or dry manure solids, prioritized for ease of maintenance and cost efficiency. The choice of bedding material significantly impacts cow comfort, hygiene, and stall durability in dairy farming.

Animal Comfort: Deep vs. Shallow Bedding

Deep bedding provides dairy cows with enhanced comfort by offering better cushioning and insulation, reducing pressure on joints and minimizing the risk of hock lesions. Shallow bedding, while less costly, often results in harder surfaces that can lead to increased cow discomfort and higher incidences of injuries. Prioritizing deep bedding in stall management significantly improves overall animal welfare and promotes longer lying times, which are crucial for cow health and milk production.

Impact on Udder Health and Mastitis Prevention

Deep bedding provides superior cushioning and moisture absorption, reducing udder contact with dirty surfaces and significantly lowering mastitis risk. In contrast, shallow bedding retains less moisture control, increasing bacterial exposure that can compromise udder health. Implementing deep bedding consistently supports improved cow comfort and effectively minimizes mastitis incidence in dairy herds.

Bedding Management and Labor Requirements

Deep bedding in dairy farming typically enhances cow comfort and reduces manure buildup by providing a thicker absorbent layer, which lowers the frequency of stall cleaning and bedding replacement. Shallow bedding requires more frequent maintenance and bedding addition, thus increasing labor demands for stall management. Effective bedding management balances cow health benefits with labor efficiency, often favoring deep bedding for long-term sustainability in dairy operations.

Cost Analysis: Deep Bedding vs. Shallow Bedding

Deep bedding in dairy stall management incurs higher upfront material costs but can reduce long-term expenses by decreasing mastitis incidence and improving cow comfort, leading to better milk yield. Shallow bedding involves lower initial investment but may result in increased labor and bedding replacement frequency, raising operational costs over time. Analyzing cost-effectiveness depends on factors like bedding material prices, labor rates, cow health metrics, and milk production efficiency.

Manure Handling and Environmental Considerations

Deep bedding in dairy stall management enhances manure absorption and reduces ammonia emissions, promoting better air quality and environmental sustainability. Shallow bedding requires more frequent manure removal and can increase labor costs and nutrient runoff risks. Effective manure handling practices combined with optimized bedding depth improve herd comfort while minimizing environmental impact.

Bedding Longevity and Maintenance Practices

Deep bedding in dairy stalls offers extended bedding longevity by providing a thicker, more absorbent layer that reduces the frequency of replacements and enhances cow comfort. Shallow bedding requires more frequent maintenance and replenishment to prevent moisture buildup and maintain hygiene, increasing labor and bedding costs. Effective stall management balances bedding depth with routine cleaning practices to optimize udder health and cow productivity.

Choosing the Right Bedding System for Your Dairy Farm

Selecting the right bedding system for dairy cow stalls hinges on factors such as cow comfort, manure management, and cost efficiency. Deep bedding typically provides better insulation and moisture absorption, promoting hoof health and reducing mastitis risk, while shallow bedding requires more frequent replacement but offers easier cleaning and lower material use. Evaluating farm-specific conditions, including climate, cow size, and labor availability, ensures an optimal balance between animal welfare and operational sustainability.

Related Important Terms

Bedding Retention Time

Deep bedding offers extended retention time by maintaining moisture and cushioning for longer periods compared to shallow bedding, which often requires more frequent replacement due to quicker compaction and contamination. Optimizing bedding retention time with deep bedding enhances cow comfort, reduces labor costs, and promotes better udder health in dairy farming operations.

Microbial Bedding Activity

Deep bedding systems enhance microbial bedding activity by providing a stable, oxygen-rich environment that promotes the growth of beneficial bacteria, which helps break down manure and maintain a healthier stall. Shallow bedding offers less microbial diversity and activity due to limited organic material and reduced moisture retention, often resulting in faster accumulation of waste and higher pathogen loads.

Bedding Pack Fermentation

Deep bedding systems promote controlled bedding pack fermentation, enhancing microbial activity that breaks down organic matter and reduces pathogens, which benefits cow comfort and udder health. Conversely, shallow bedding tends to have less effective fermentation, leading to quicker moisture accumulation and increased risks of mastitis and hoof diseases in dairy cows.

Dry Matter Bedding Depth

Deep bedding with a dry matter depth of 15-20 cm enhances cow comfort and reduces udder infections compared to shallow bedding at 5-10 cm, which may lead to increased moisture and bacterial growth. Proper dry matter depth in deep bedding improves stall hygiene, animal welfare, and manure management efficiency in dairy farming operations.

Heat Stress Bedding Management

Deep bedding in dairy stalls provides superior insulation and moisture absorption compared to shallow bedding, reducing heat stress by maintaining cooler, drier lying surfaces for cows. Effective stall management with deep bedding enhances cow comfort and productivity by minimizing heat load and promoting better thermoregulation during hot weather.

Ammonia Emission Control

Deep bedding in dairy stall management significantly reduces ammonia emissions by absorbing and binding manure more effectively than shallow bedding, which tends to allow faster ammonia volatilization. Utilizing deep bedding composed of materials like straw or wood shavings enhances microbial activity that breaks down nitrogen compounds, thereby improving air quality and promoting healthier conditions for dairy cattle.

Bedding Mat Compression

Deep bedding in dairy farming provides enhanced cushioning for cows, reducing bedding mat compression and improving udder health by minimizing pressure points. Shallow bedding, while cost-effective, often leads to increased mat compression, resulting in reduced comfort and higher risks of mastitis due to inadequate cushioning.

Organic Bedding Load

Deep bedding systems utilize a thicker layer of organic materials such as straw or sawdust, enhancing manure absorption and providing better comfort for dairy cows compared to shallow bedding, which uses a minimal layer and often requires more frequent replacement. Organic bedding load in deep bedding setups promotes microbial activity that aids in nutrient recycling and improves stall hygiene, ultimately reducing pathogen buildup and enhancing udder health.

Stall Surface Thermoregulation

Deep bedding provides superior stall surface thermoregulation by maintaining consistent temperature and enhancing cow comfort through better insulation compared to shallow bedding, which tends to allow greater temperature fluctuations and increased moisture retention. Optimized thermoregulation in deep bedding reduces heat stress and improves udder health, critical factors for maximizing dairy cow productivity and welfare.

Cow Comfort Index Bedding

Deep bedding in dairy stall management significantly enhances the Cow Comfort Index (CCI) by providing improved cushioning and moisture absorption, reducing hock injuries and increasing lying times. Conversely, shallow bedding often results in lower CCI scores due to insufficient padding and higher exposure to moisture, leading to discomfort and increased stress in dairy cows.

Deep Bedding vs Shallow Bedding for Stall Management Infographic

agridif.com

agridif.com