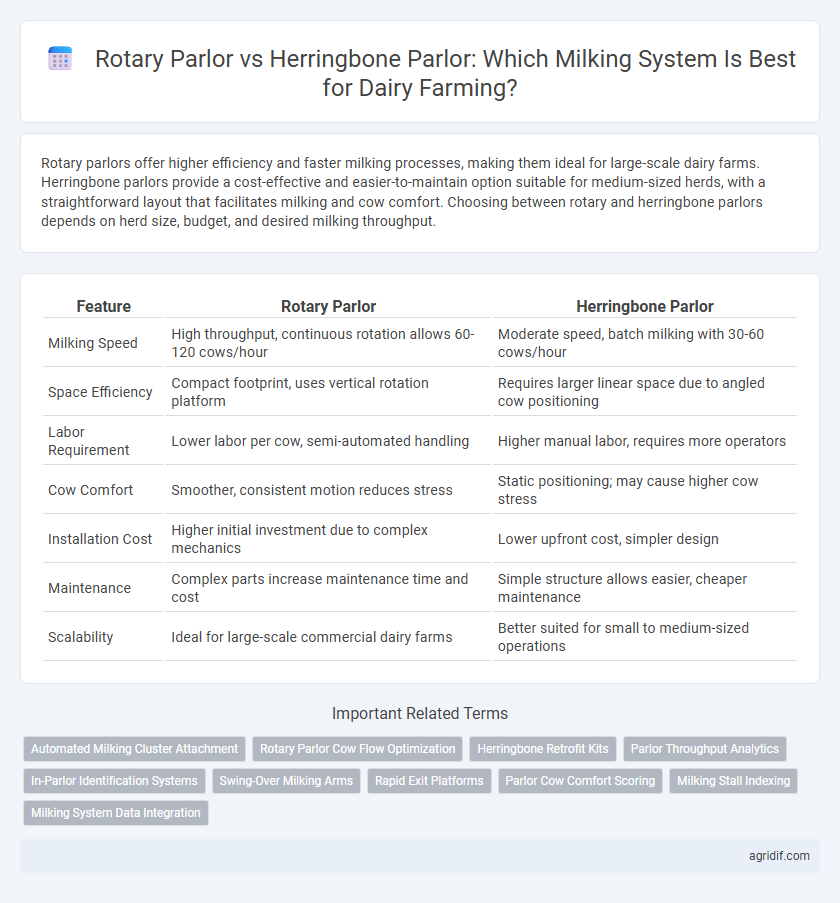

Rotary parlors offer higher efficiency and faster milking processes, making them ideal for large-scale dairy farms. Herringbone parlors provide a cost-effective and easier-to-maintain option suitable for medium-sized herds, with a straightforward layout that facilitates milking and cow comfort. Choosing between rotary and herringbone parlors depends on herd size, budget, and desired milking throughput.

Table of Comparison

| Feature | Rotary Parlor | Herringbone Parlor |

|---|---|---|

| Milking Speed | High throughput, continuous rotation allows 60-120 cows/hour | Moderate speed, batch milking with 30-60 cows/hour |

| Space Efficiency | Compact footprint, uses vertical rotation platform | Requires larger linear space due to angled cow positioning |

| Labor Requirement | Lower labor per cow, semi-automated handling | Higher manual labor, requires more operators |

| Cow Comfort | Smoother, consistent motion reduces stress | Static positioning; may cause higher cow stress |

| Installation Cost | Higher initial investment due to complex mechanics | Lower upfront cost, simpler design |

| Maintenance | Complex parts increase maintenance time and cost | Simple structure allows easier, cheaper maintenance |

| Scalability | Ideal for large-scale commercial dairy farms | Better suited for small to medium-sized operations |

Introduction to Milking Parlor Systems

Rotary parlor systems increase milking efficiency by allowing multiple cows to be milked simultaneously on a rotating platform, optimizing throughput on large-scale dairy farms. Herringbone parlors feature cows positioned at an angle to the milking pit, facilitating easy attachment of milking machines and efficient worker movement in medium-sized operations. Both systems enhance milk quality and animal comfort through automated processes and hygienic design tailored to different farm capacities.

Understanding Rotary Parlor Design

Rotary parlor design offers continuous milking by rotating cows on a circular platform, enhancing efficiency and throughput compared to the fixed stalls in herringbone parlors. This system optimizes labor by allowing multiple cows to be milked simultaneously, reducing downtime between sessions. Key features include automated teat cleaning, precise milk monitoring, and ergonomic operator stations, making rotary parlors ideal for large-scale dairy farms seeking increased productivity and animal comfort.

Overview of Herringbone Parlor Configuration

Herringbone parlor configuration features cows arranged at an angle, typically 45 to 60 degrees, to the milking pit, allowing efficient access to the udder for milking. This system accommodates 8 to 12 cows per unit, suitable for medium-sized dairy farms, promoting ease of cleaning and maintenance with a straightforward design. Herringbone parlors optimize labor efficiency and milking speed while maintaining cow comfort, making them a common choice for balanced performance and cost-effectiveness in dairy farming operations.

Comparison of Milking Efficiency

Rotary parlors offer higher milking efficiency by enabling continuous cow flow and reduced handling time, typically processing 60-120 cows per hour, compared to herringbone parlors which handle 30-60 cows per hour with more frequent stops. The rotary system's automated cleaning and cluster attachment reduce labor intensity and milking duration per cow, improving throughput. Herringbone parlors, while simpler and less costly, often result in longer milking sessions and lower overall productivity for large-scale dairy operations.

Labor Requirements and Workforce Optimization

Rotary parlors drastically reduce labor requirements by allowing one operator to manage multiple cows simultaneously through continuous rotation, enhancing workforce efficiency. Herringbone parlors demand more manual labor as operators must move between cows to attach and detach milking units individually, increasing time and labor intensity. Choosing a rotary parlor optimizes workforce allocation by streamlining milking processes and lowering the need for additional labor, especially in large-scale dairy operations.

Animal Comfort and Welfare Considerations

Rotary parlors provide consistent, gentle handling and continuous movement, reducing cow stress and promoting better animal comfort during milking. Herringbone parlors offer straightforward access to udders but may cause more standing time, potentially increasing discomfort and stress. Prioritizing proper stall design and minimizing milking duration are essential for optimizing animal welfare in both systems.

Space and Infrastructure Requirements

Rotary parlors require a larger circular space and specialized rotating platforms, making them suitable for high-capacity dairy farms with sufficient infrastructure investment. Herringbone parlors demand less floor space and have simpler structural needs, often fitting into smaller barns or existing facilities more easily. Space efficiency and initial infrastructure costs are critical factors when selecting between rotary and herringbone milking systems in dairy farming operations.

Installation and Maintenance Costs

Rotary parlors demand higher initial installation costs due to complex mechanical components and larger space requirements, but offer efficient animal throughput that can offset expenses over time. Herringbone parlors typically have lower upfront installation costs, featuring simpler structural designs suited for small to medium-sized herds, resulting in easier and less costly maintenance. Maintenance for rotary systems often involves specialized technicians and more expensive parts, whereas herringbone parlors benefit from straightforward mechanics, reducing ongoing repair expenses.

Technological Integration and Automation

Rotary parlors offer advanced technological integration with fully automated milking processes, enhancing efficiency and cow comfort through continuous rotation and sensor-driven data collection. Herringbone parlors feature semi-automated systems with manual intervention for attach and detach steps, providing moderate automation suitable for smaller herds or budget-conscious operations. The choice between rotary and herringbone systems depends on herd size and automation needs, with rotary parlors excelling in high-volume, tech-intensive dairy farms.

Choosing the Right Parlor System for Your Dairy Farm

Rotary parlors offer high throughput capacity, ideal for large-scale dairy farms aiming to maximize milking efficiency and minimize labor costs. Herringbone parlors provide a more compact, cost-effective solution suitable for smaller herds with easier maintenance and quicker cow turnover. Evaluating herd size, budget constraints, and farm layout is crucial to selecting a milking system that aligns with operational goals and enhances overall productivity.

Related Important Terms

Automated Milking Cluster Attachment

Rotary parlor systems excel in automated milking cluster attachment by enabling continuous cow rotation with minimal manual intervention, enhancing throughput and operational efficiency in large-scale dairy farms. Herringbone parlors, while simpler and less costly, often require more frequent manual cluster attachment and detachment, limiting automation potential and reducing overall milking speed.

Rotary Parlor Cow Flow Optimization

Rotary parlors enhance cow flow optimization by allowing continuous, smooth rotation of cows through the milking process, reducing wait times and improving throughput compared to the stop-and-go nature of herringbone parlors. This design minimizes cow stress and maximizes milking efficiency, making rotary systems ideal for high-volume dairy operations seeking optimal productivity.

Herringbone Retrofit Kits

Herringbone retrofit kits enhance traditional herringbone parlors by upgrading milking technology for improved efficiency and cow comfort, offering a cost-effective alternative to investing in rotary parlors. These kits optimize vacuum systems and pulsation control, increasing milk yield and reducing labor without the need for extensive facility modifications.

Parlor Throughput Analytics

Rotary parlors achieve higher parlor throughput rates, milking up to 60-100 cows per hour, compared to herringbone parlors, which typically handle 30-60 cows per hour, optimizing overall dairy farm efficiency. The continuous cow flow and automated milking clusters in rotary systems reduce stall idle time and labor intensity, enhancing milk output and operational productivity in large-scale dairy operations.

In-Parlor Identification Systems

Rotary parlor milking systems integrate advanced in-parlor identification technologies like RFID tags and automated milk meters, enabling real-time data collection for each cow's health and production monitoring. In contrast, herringbone parlors use simpler identification methods, often requiring more manual intervention, which may reduce efficiency in large-scale dairy operations.

Swing-Over Milking Arms

Rotary parlors feature Swing-Over Milking Arms that allow efficient cow turnaround and minimize downtime by enabling simultaneous detachment and attachment of units, significantly increasing throughput compared to the stationary arms in herringbone parlors. Herringbone parlors, while easier to maintain and less expensive, have fixed positions that limit flexibility and slow the milking process, making rotary systems with Swing-Over Arms preferable for large-scale dairy operations seeking higher efficiency.

Rapid Exit Platforms

Rotary parlor systems significantly enhance milking efficiency by incorporating rapid exit platforms that allow cows to leave quickly after milking, reducing wait times and increasing throughput. In contrast, herringbone parlors lack rapid exit mechanisms, often resulting in slower cow flow and decreased overall milking capacity.

Parlor Cow Comfort Scoring

Rotary parlors provide a continuous, gentle milking process that scores higher in cow comfort due to reduced standing time and smoother entry and exit, enhancing udder health and milk yield. Herringbone parlors, while effective, often score lower on comfort because cows experience longer wait times and less ergonomic positioning, potentially increasing stress and mastitis risk.

Milking Stall Indexing

Rotary parlors offer continuous milking stall indexing allowing cows to enter and exit efficiently, significantly enhancing throughput compared to the fixed-position stalls of herringbone parlors. This dynamic indexing system reduces cow handling time and increases milking capacity, making rotary parlors ideal for large-scale dairy operations.

Milking System Data Integration

Rotary parlors offer superior milking system data integration by enabling continuous real-time monitoring of individual cow milk yield, flow rates, and health indicators through automated sensors, enhancing herd management efficiency. Herringbone parlors, while offering batch data collection, lack the seamless, high-frequency data capture and analysis capabilities that rotary systems provide for precision dairy farming.

Rotary Parlor vs Herringbone Parlor for milking system Infographic

agridif.com

agridif.com