Rotary parlours offer higher efficiency and faster milking times ideal for large-scale dairy farming, optimizing cow flow and reducing labor costs. Herringbone parlours provide better accessibility to each cow, making them suitable for smaller herds with a focus on animal comfort and ease of maintenance. Choosing between these systems depends on herd size, farm management goals, and the balance between speed and individual cow care.

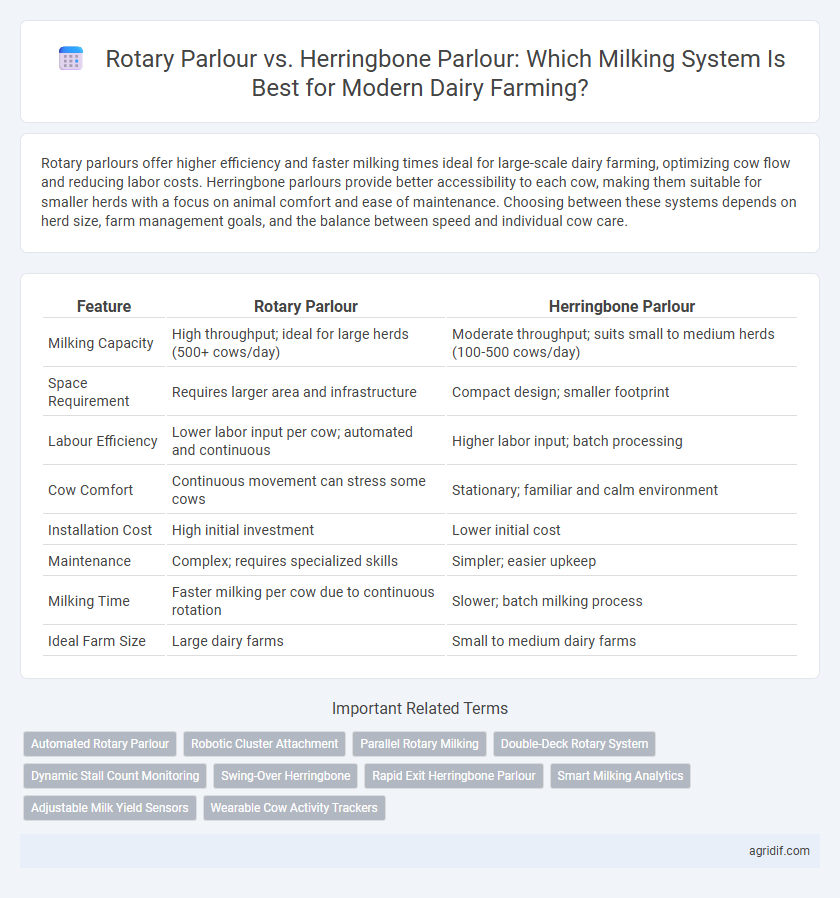

Table of Comparison

| Feature | Rotary Parlour | Herringbone Parlour |

|---|---|---|

| Milking Capacity | High throughput; ideal for large herds (500+ cows/day) | Moderate throughput; suits small to medium herds (100-500 cows/day) |

| Space Requirement | Requires larger area and infrastructure | Compact design; smaller footprint |

| Labour Efficiency | Lower labor input per cow; automated and continuous | Higher labor input; batch processing |

| Cow Comfort | Continuous movement can stress some cows | Stationary; familiar and calm environment |

| Installation Cost | High initial investment | Lower initial cost |

| Maintenance | Complex; requires specialized skills | Simpler; easier upkeep |

| Milking Time | Faster milking per cow due to continuous rotation | Slower; batch milking process |

| Ideal Farm Size | Large dairy farms | Small to medium dairy farms |

Introduction to Milking Systems in Dairy Farming

Rotary parlours offer continuous, circular milking with high throughput, making them ideal for large-scale dairy farms aiming for efficiency. In contrast, Herringbone parlours arrange cows in angled stalls, providing straightforward access and easier cow handling for moderate herd sizes. Both systems impact milking speed, labour requirements, and cow comfort, essential factors in optimizing dairy farm productivity.

Overview of Rotary Parlour Milking Systems

Rotary parlour milking systems feature a circular platform that rotates continuously, allowing cows to enter, be milked, and exit efficiently in a streamlined process. These systems enhance milking speed and capacity, accommodating large herds by minimizing cow stress and improving operator ergonomics. Integration of automated cluster removal and milk flow monitoring contributes to higher productivity and milking consistency compared to traditional herringbone parlours.

Overview of Herringbone Parlour Milking Systems

Herringbone parlour milking systems feature stalls arranged at an angle resembling a fish skeleton, allowing cows to stand in a V-shaped formation for efficient milking. This design facilitates easy access to the udder, simplifying the attachment of milking units and improving worker ergonomics. Herringbone parlours are typically suited for medium-sized herds, offering lower installation costs and straightforward maintenance compared to rotary systems.

Efficiency and Throughput Comparison

Rotary parlours offer higher throughput and greater efficiency compared to herringbone parlours by enabling continuous cow rotation and milking, reducing idle time and increasing the number of cows milked per hour. Herringbone parlours typically process cows in batches, which can limit milking speed and result in longer waiting times. Farms aiming for maximum milking efficiency and increased daily output often prefer rotary systems due to their streamlined workflow and capacity for handling large herds.

Labor Requirements and Workforce Management

Rotary parlors require fewer laborers due to automated, continuous milking processes that streamline workflow and reduce manual handling, enhancing overall efficiency in large-scale dairy operations. Herringbone parlors demand more workforce involvement, as each cow must be manually attached and detached, increasing labor intensity and supervision needs. Effective workforce management in rotary systems centers on technical skills and maintenance, while herringbone parlors prioritize operational staffing and manual dexterity.

Animal Comfort and Welfare Considerations

Rotary parlours provide continuous movement, reducing stress and improving cow flow, which enhances overall animal comfort during milking. Herringbone parlours offer more stationary milking stalls, allowing for easier individual cow monitoring but may result in longer waiting times that can increase animal stress. Both systems require proper design and management to optimize cow welfare by minimizing handling time and ensuring gentle milking procedures.

Installation and Maintenance Costs

Rotary parlours generally involve higher installation costs due to their complex mechanical structures and larger space requirements compared to Herringbone parlours, which are simpler and more compact. Maintenance expenses for rotary systems tend to be elevated because of sophisticated moving parts requiring specialized upkeep, while Herringbone parlours benefit from easier access and fewer components, reducing ongoing service costs. Choosing between these systems depends on the scale of the dairy operation and budget constraints related to initial investment and long-term maintenance affordability.

Space and Infrastructure Needs

Rotary parlors require a larger footprint and more complex infrastructure, including advanced mechanization and automation systems, making them suitable for large-scale dairy farms with extensive space availability. Herringbone parlors demand less space and simpler structural setups, fitting better into farms with limited area and lower capital investment capacity. Designing milking systems must consider these differences to optimize operational flow and facility layout.

Technological Integration and Automation

Rotary parlours offer advanced technological integration with automated milking systems, enabling continuous cow flow and real-time data collection for improved efficiency and animal health monitoring. Herringbone parlours, while effective, typically incorporate less automation, relying more on manual labor for cow positioning and milking processes. The rotary design supports seamless integration with robotic arms and sensor technologies, optimizing milk yield and reducing operator fatigue compared to the more traditional herringbone setup.

Choosing the Best Parlour System for Your Dairy Farm

Rotary parlours offer higher throughput and efficiency for large dairy farms with herds exceeding 200 cows, enabling continuous milking and reducing labor costs. Herringbone parlours provide greater flexibility and are better suited for small to medium-sized farms, allowing easier cow access and simpler maintenance. Selecting between rotary and herringbone systems depends on herd size, farm layout, labor availability, and investment budget to optimize milking performance and animal welfare.

Related Important Terms

Automated Rotary Parlour

Automated rotary parlours in dairy farming enhance milking efficiency by allowing continuous, high-speed milking with minimal labor, outperforming traditional herringbone parlours that require more manual intervention and slower throughput. Advanced sensors and robotic arms in automated rotary systems ensure optimal teat stimulation and hygiene, leading to increased milk yield and improved animal welfare compared to conventional herringbone parlours.

Robotic Cluster Attachment

Rotary parlours offer faster milking throughput with automated robotic cluster attachment systems that enhance efficiency and reduce labor dependency compared to herringbone parlours, which rely more on manual cluster placement. Robotic cluster attachment in rotary systems improves animal welfare by minimizing stress and ensures consistent milking routines through precise, sensor-driven alignment technology.

Parallel Rotary Milking

Parallel rotary milking systems enhance efficiency by combining the continuous rotation of rotary parlours with the parallel alignment of cows, reducing milking time and improving cow comfort compared to traditional herringbone parlours. This system optimizes space usage and labor, resulting in higher throughput and better udder health management in dairy farming operations.

Double-Deck Rotary System

The Double-Deck Rotary System enhances milking efficiency by accommodating more cows per cycle compared to traditional Herringbone parlours, significantly reducing milking time while maintaining animal comfort. This rotary parlour's elevated design optimizes space usage and streamlines workflow, offering higher throughput and improved herd management in large-scale dairy farming operations.

Dynamic Stall Count Monitoring

Rotary parlours offer advanced dynamic stall count monitoring by continuously tracking each cow's milking session, enabling real-time adjustments to optimize throughput and minimize cow stress. In contrast, herringbone parlours provide static stall counts with limited real-time monitoring capabilities, often requiring manual data collection that can delay responsiveness and reduce overall efficiency.

Swing-Over Herringbone

Swing-Over Herringbone parlours offer a cost-effective milking system with flexible cow positioning, allowing one cluster to swing over to the next stall, optimizing labor efficiency while maintaining milking speed. Rotary parlours provide continuous cow movement and higher throughput but require greater capital investment and space compared to the modular and lower-capacity Swing-Over Herringbone design.

Rapid Exit Herringbone Parlour

The Rapid Exit Herringbone Parlour enhances milking efficiency by allowing cows to leave the stall quickly after milking, reducing wait times and increasing throughput compared to traditional herringbone systems. Unlike Rotary Parlours, which operate continuously in a circular motion, Rapid Exit Herringbone Parlours combine stall batch processing with faster cow turnover, improving overall herd milking speed and animal welfare.

Smart Milking Analytics

Rotary parlours offer continuous, high-throughput milking with integrated smart milking analytics that provide real-time data on milk yield, cow health, and milking efficiency, enabling precision management and early detection of issues. Herringbone parlours, while simpler and lower-cost, generally collect less detailed data, limiting the depth of analytics and insights available for optimizing herd performance and resource use.

Adjustable Milk Yield Sensors

Rotary parlours offer continuous rotation allowing adjustable milk yield sensors to monitor individual cows in real-time, optimizing milking efficiency and data accuracy. Herringbone parlours incorporate stationary stalls with adjustable sensors that measure milk yield per cow, providing reliable data but with less throughput compared to rotary systems.

Wearable Cow Activity Trackers

Rotary parlours offer higher milking throughput and better integration with wearable cow activity trackers that continuously monitor cow health, optimizing herd management by early detection of lameness and estrus. In contrast, herringbone parlours provide easier access for individual cow handling but may limit real-time data collection and responsiveness from wearable sensors during milking.

Rotary parlour vs Herringbone parlour for milking systems Infographic

agridif.com

agridif.com