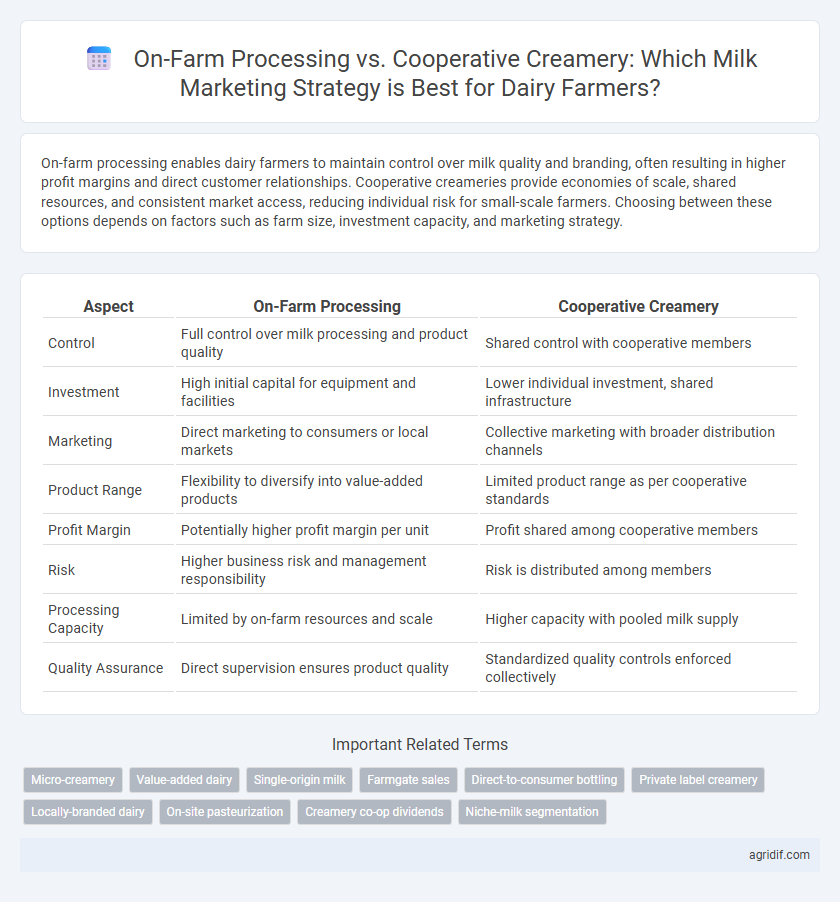

On-farm processing enables dairy farmers to maintain control over milk quality and branding, often resulting in higher profit margins and direct customer relationships. Cooperative creameries provide economies of scale, shared resources, and consistent market access, reducing individual risk for small-scale farmers. Choosing between these options depends on factors such as farm size, investment capacity, and marketing strategy.

Table of Comparison

| Aspect | On-Farm Processing | Cooperative Creamery |

|---|---|---|

| Control | Full control over milk processing and product quality | Shared control with cooperative members |

| Investment | High initial capital for equipment and facilities | Lower individual investment, shared infrastructure |

| Marketing | Direct marketing to consumers or local markets | Collective marketing with broader distribution channels |

| Product Range | Flexibility to diversify into value-added products | Limited product range as per cooperative standards |

| Profit Margin | Potentially higher profit margin per unit | Profit shared among cooperative members |

| Risk | Higher business risk and management responsibility | Risk is distributed among members |

| Processing Capacity | Limited by on-farm resources and scale | Higher capacity with pooled milk supply |

| Quality Assurance | Direct supervision ensures product quality | Standardized quality controls enforced collectively |

Introduction to Milk Marketing Strategies

On-farm processing allows dairy farmers to convert raw milk into value-added products such as cheese, yogurt, and butter, enabling direct sales to consumers and higher profit margins. Cooperative creameries aggregate milk from multiple producers, offering economies of scale, consistent quality standards, and broader market access through collective bargaining power. Choosing the right milk marketing strategy depends on farm size, production capacity, and access to processing facilities, influencing income stability and market reach.

Overview of On-Farm Milk Processing

On-farm milk processing allows dairy farmers to pasteurize, package, and market milk products directly from their farms, increasing profit margins and control over product quality. This method reduces reliance on external cooperatives and shortens the supply chain, enabling faster response to consumer demands and increased traceability. Investments in processing equipment and adherence to food safety regulations are critical factors in successfully implementing on-farm milk processing.

Understanding Cooperative Creameries

Cooperative creameries enable dairy farmers to collectively process and market milk, enhancing bargaining power and access to larger markets compared to on-farm processing. These cooperatives provide shared facilities for pasteurization, bottling, and quality control, ensuring consistent product standards and compliance with regulatory requirements. By leveraging economies of scale, cooperative creameries reduce individual costs and increase profitability for member farmers.

Cost Analysis: On-Farm vs Cooperative Processing

On-farm processing incurs higher initial capital investment due to equipment purchase, maintenance, and compliance with hygiene standards, whereas cooperative creameries distribute processing costs across multiple producers, lowering individual expenses. Variable costs such as labor and energy tend to be more manageable in cooperative setups because of shared resources and economies of scale. Producers must balance on-farm processing control and potential premium pricing against cooperative creamery efficiency and reduced financial risk.

Quality Control and Product Differentiation

On-farm processing allows dairy farmers to maintain stringent quality control by directly overseeing milk handling, ensuring freshness and reducing contamination risks. Cooperative creameries enable pooled resources for advanced quality testing and standardization, supporting consistent product differentiation through scale and innovation. Both methods impact milk marketing strategies by balancing control over product attributes with access to broader distribution networks.

Market Access and Distribution Channels

On-farm processing enables dairy farmers to retain control over product quality and directly access niche markets, often resulting in higher profit margins and personalized brand development. Cooperative creameries offer extensive distribution channels and bulk marketing power, facilitating access to larger regional and national markets with reduced individual handling costs. Balancing on-farm processing with cooperative partnerships optimizes market reach while maintaining product integrity and farmer autonomy.

Profitability and Economic Sustainability

On-farm processing allows dairy farmers to capture higher profit margins by directly selling value-added products like cheese and yogurt, enhancing economic sustainability through diversified income streams. Cooperative creameries offer collective bargaining power and reduced processing costs, improving profitability via economies of scale but often at the expense of individual price control. Strategic alignment with market demand and operational capacity determines whether on-farm processing or cooperative marketing maximizes long-term financial viability for dairy producers.

Regulatory Compliance and Certification Requirements

On-farm processing offers greater control over regulatory compliance, requiring farmers to meet state-specific milk safety and sanitation standards, including regular inspections and adherence to Pasteurized Milk Ordinance (PMO) guidelines. Cooperative creameries often manage certification requirements centrally, ensuring compliance with federal and state regulations such as the Grade A Pasteurized Milk certification, reducing individual farmer burden. Both options demand strict adherence to food safety protocols like Hazard Analysis Critical Control Point (HACCP) plans, but cooperatives may provide added resources for maintaining certifications and meeting evolving regulatory standards.

Community Impact and Farmer Collaboration

On-farm processing empowers dairy farmers by allowing them to retain a larger share of profits and maintain control over product quality, fostering a strong sense of community pride. Cooperative creameries enhance farmer collaboration by pooling resources, sharing expertise, and stabilizing market access, which strengthens local economies and supports collective bargaining power. Both models contribute significantly to rural development, with cooperatives promoting social cohesion and on-farm processing encouraging entrepreneurial innovation among farmers.

Future Trends in Dairy Marketing Approaches

On-farm processing offers dairy farmers greater control over product quality and direct access to niche markets, leveraging increasing consumer demand for locally produced and artisanal dairy goods. Cooperative creameries provide economies of scale and access to broader distribution networks, enhancing bargaining power in competitive global markets. Future trends in dairy marketing emphasize digital platforms and blockchain for transparent supply chains, enabling both on-farm processors and cooperatives to build consumer trust and respond agilely to dynamic market demands.

Related Important Terms

Micro-creamery

Micro-creamery on-farm processing enhances milk marketing by allowing dairy farmers to retain higher profit margins through direct sales and customized product offerings, contrasting with cooperative creameries which often involve collective milk pooling and standardized pricing. This approach supports local branding and traceability while reducing dependency on large-scale cooperatives, fostering greater control over quality and market positioning.

Value-added dairy

On-farm processing enables dairy farmers to directly produce value-added products like cheese and yogurt, capturing higher profit margins through local branding and customized offerings. Cooperative creameries leverage collective volume to access larger markets and shared resources, enhancing economies of scale while distributing value-added profits among members.

Single-origin milk

On-farm processing of single-origin milk enables dairy farmers to maintain complete control over product quality, traceability, and brand differentiation, enhancing farm-to-table appeal for niche markets. Cooperative creameries offer scale economies and established distribution networks but may dilute single-origin identity due to mixed milk sourcing and standardized processing.

Farmgate sales

Farmgate sales through on-farm processing allow dairy farmers to capture higher profit margins by directly controlling product quality and pricing, reducing dependency on external markets. In contrast, cooperative creameries offer collective bargaining power and access to larger distribution networks but often result in lower farmgate prices due to shared profit structures.

Direct-to-consumer bottling

On-farm processing enables dairy farmers to maintain control over milk quality and branding through direct-to-consumer bottling, increasing profit margins by bypassing intermediaries. Cooperative creameries offer economies of scale and collective marketing power but often limit individual farm branding and reduce direct consumer engagement opportunities.

Private label creamery

Private label creameries empower dairy farmers by allowing on-farm processing that enhances product control, quality assurance, and direct brand positioning, leading to higher profit margins compared to cooperative creameries. Utilizing private label options enables tailored marketing strategies and niche product development, optimizing farm-level revenue streams in competitive dairy markets.

Locally-branded dairy

On-farm processing enables farmers to create unique, locally-branded dairy products that directly connect with consumers, enhancing farm identity and capturing higher profit margins. Cooperative creameries offer economies of scale and wider distribution networks, yet may dilute local branding efforts, limiting the distinctiveness of dairy marketed under regional or farm-specific names.

On-site pasteurization

On-site pasteurization in on-farm processing enhances milk quality control and reduces transportation costs by allowing farmers to handle milk directly from production to packaging. This method increases product freshness and market responsiveness compared to cooperative creameries, which often involve batch processing and centralized distribution delays.

Creamery co-op dividends

On-farm processing allows dairy farmers to retain greater control over product quality and capture higher profit margins by selling directly to consumers, while cooperative creameries offer stability through shared processing infrastructure and established market access. Creamery co-op dividends provide members with a financial return based on the volume and quality of milk supplied, enhancing overall income by distributing profits back to participating farmers.

Niche-milk segmentation

On-farm processing enables dairy farmers to directly market niche milk products such as organic, raw, or specialty cheeses, capturing higher margins through brand differentiation and consumer trust. Cooperative creameries facilitate access to larger markets and collective bargaining power but often standardize products, limiting opportunities for niche segmentation and premium pricing.

On-farm processing vs Cooperative creamery for milk marketing Infographic

agridif.com

agridif.com